Lean manufacturing, a standalone Industry 4.0 project

By OEM Update Editorial June 18, 2019 12:43 pm IST

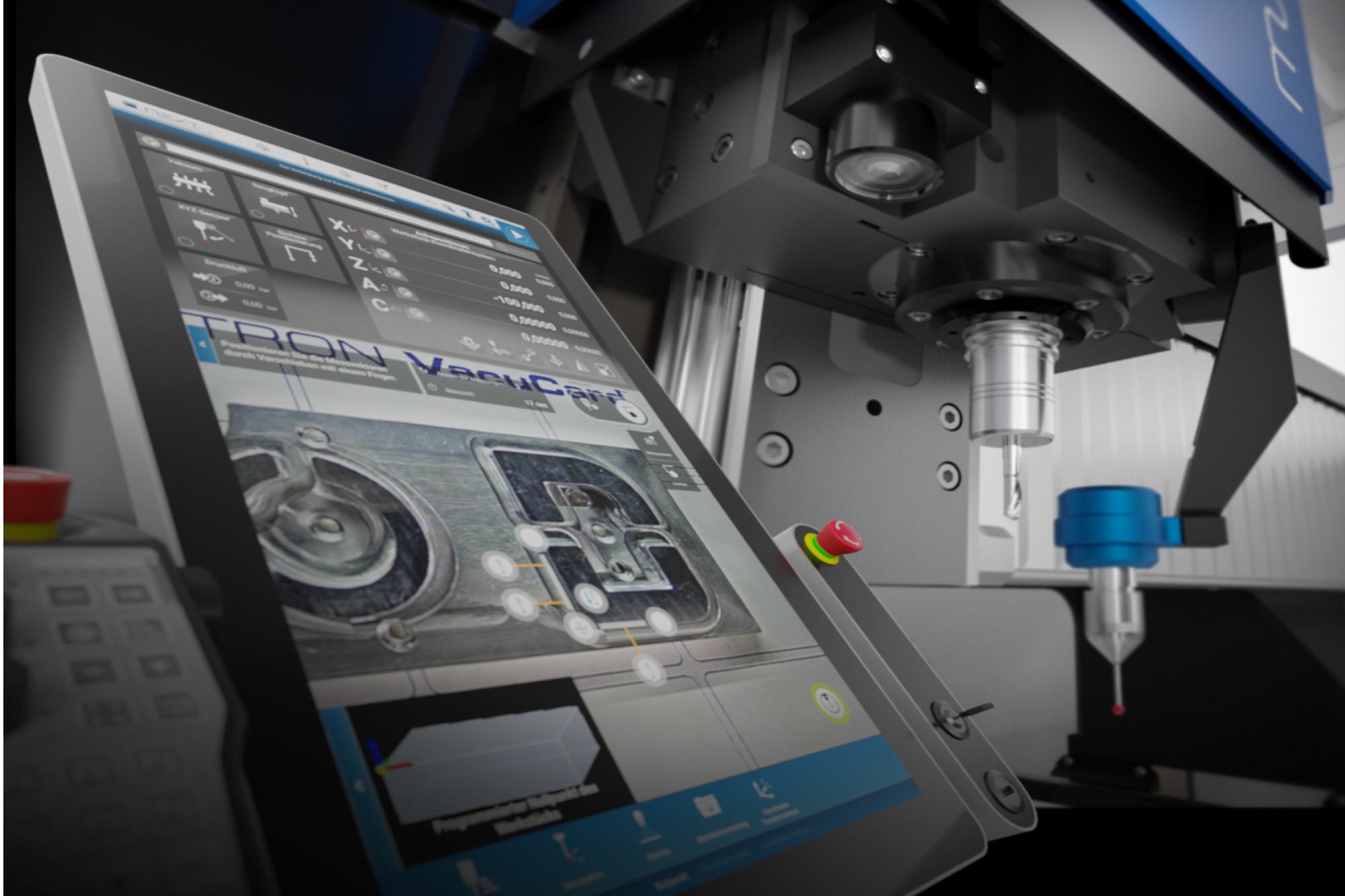

Manufacturers generate efficiency improvement of 10-15 per cent by incorporating digital work and robotics into their production lines, says Mayank Tripathi – Area Sales Manager – Hurco India Pvt. Ltd. in a discussion with Athira Bejoy of OEM Update.

Mudra loan ensuring repayment, posed by the MSMEs, is still a challenge

Mudra has restored the confidence of people in the system as there is no discrimination for getting loans under the scheme. It has brought many poor citizens into financial mainstream with NBFCs and microfinance institutions coming on board.

Even if loans are sought by business owners genuinely seeking growth and bankers disburse them with an eye on economic development, ensuring repayment is still a challenge. First, these loans are unsecured — a collateral that could protect the interests of the bank is not required, unless an asset that is purchased can itself serve as collateral. The scheme is meant for those who need small amounts, but do not have access to such funds, but the very nature of the business of such borrowers is susceptible to volatility and annual cycles, not to mention the itinerant ways of some business owners, such as vegetable vendors. They may choose one location for their place of business on a day, and another elsewhere in their city the next day. Further, the public banking system may not be staffed for work this may entail. When it comes to collection, bank staff may choose to go after one loan with outstanding of ₹10 lakh, for example, rather than 10 loans of ₹1,00,000 each.

India, an attractive destination for investments

With the help of Make in India drive, India is on the path of becoming the hub for hi-tech manufacturing global giants such as GE, Siemens, HTC, Toshiba, and Boeing have either set up or are in process of setting up manufacturing plants in India. Cumulative FDI in India’s manufacturing sector reached $46.62 billion during April 2000-December 2018. India’s market is of more than a billion consumers with increasing purchasing power. India has become one of the most attractive destinations for investments in the manufacturing sector. India is expected to become the fifth largest manufacturing country in the world by the end of year 2020.

Digital India, needs to be more user-centric

Digital India, the flagship program of the Indian government, hinges on connecting every Indian citizen to e-governance and basic services through the digital medium, providing all information that is needed at one’s fingertips. Challenges are creating of infrastructure, affordable internet access, smartphones, IT backbone, government websites etc., in my opinion, is never enough. You could create everything, and still have no users! In my view, user centricity and relevance are key to success of Digital India, more than access or affordability.

The to-do list for changing the face of India

India’s engineering talent pool is second to none. Indian engineers have skills that you cannot find anywhere else in the world. Specifically, Indian engineers have a rare capacity for devising creative solutions with limited resources. The few areas that need immediate attention to translate this vision into success would be; a) skill development, as industry require graduates with specific skill sets. The government must invest more and more in developing truly skilled graduates – not just degree holders; b) import duty relaxation as in this mechanised world, it is impossible to thrive without the integration of technology and infrastructure. In order to support all the investment that will go into developing the manufacturing sector, the government need to provide relaxation in technological imports (machinery and others); c) infrastructure, as its deficit represents a major stumbling block. Land acquisition apart, challenges faced by India’s energy sector pose a big hurdle; d) inducement on innovation, as increasingly, if India is to realise its potential as a global manufacturing hub it must take responsibility for innovating and developing the products that it then manufactures for sale into India and around the world.

Lean manufacturing’s reshaping the machining sector

Lean is about transforming your business culture. Like previous industrial revolutions, new technological developments are driving Industry 4.0 forward. The most relevant of these new technologies for lean manufacturers are cyber-physical systems (CPS) and the industrial internet of things (IIoT). Fear of automation, and other manufacturing workforce challenges, make it easy to overlook the potential positive cultural impact from these technologies. For lean manufacturers, this new technology is an opportunity to ace enabling industry 4.0 technologies with tools that can make manufacturers more flexible, efficient, and profitable.

Manufacturers generate efficiency improvement of 10-15 per cent by incorporating digital work and robotics into their production lines. This is a stand-alone Industry 4.0 project. However, these projects need to be implemented and designed correctly in order to yield these improvements. Also, they can be difficult to change if they’re highly customised.

The roadmap for the future

The manufacturing sector of India has the potential to reach US$ 1 trillion by 2025 and India is expected to rank amongst the top three growth economies and manufacturing destination of the world by the year 2020. The implementation of GST will make India a common market with a GDP of $2.5 trillion along with a population of 1.32 billion people, which will be a big draw for investors.

With impetus on developing industrial corridors and smart cities, the government aims to ensure holistic development of the nation. The corridors would further assist in integrating, monitoring and developing a conducive environment for the industrial development and will promote advance practices in manufacturing.

Indian engineers have skills that you won’t find anywhere else in the world; a rare capacity for devising creative solutions with limited resources

Mayank Tripathi, Area Sales Manager, Hurco India Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.