India is a crucial market for us: Fritz Studer AG

By OEM Update Editorial February 28, 2024 3:29 pm IST

In February, Fritz Studer AG held a musically coveted Motion Meeting 2024 press conference at its headquarters in Steffisburg, Switzerland. Sandro Bottazzo, Chief Sales Officer and Daniel Huber, Chief Technology Officer, discussed the intersection of music and machine operations and the global market trends with OEM Update.

Every year in Motion Meeting, you develop a theme; this year, you synchronise that with music. What is the concept behind it?

Sandro: We adopt a new theme each year. This year, it is “The Sound of Studer.” Music serves a greater purpose beyond mere auditory pleasure. It is us fostering emotions and pleasure in our customers and listeners. This sentiment extends to our grinding machines as well. We aim to instil positive feelings in our customers. We wish to ensure a satisfying experience with our machines, ultimately leading to the financial success of our users. Developing and musing a song requires dedication and hard work, much like grinding machines’ development and manufacturing process. So we here endeavoured to showcase the teamwork and wealth of experience that goes into crafting music and our machines.

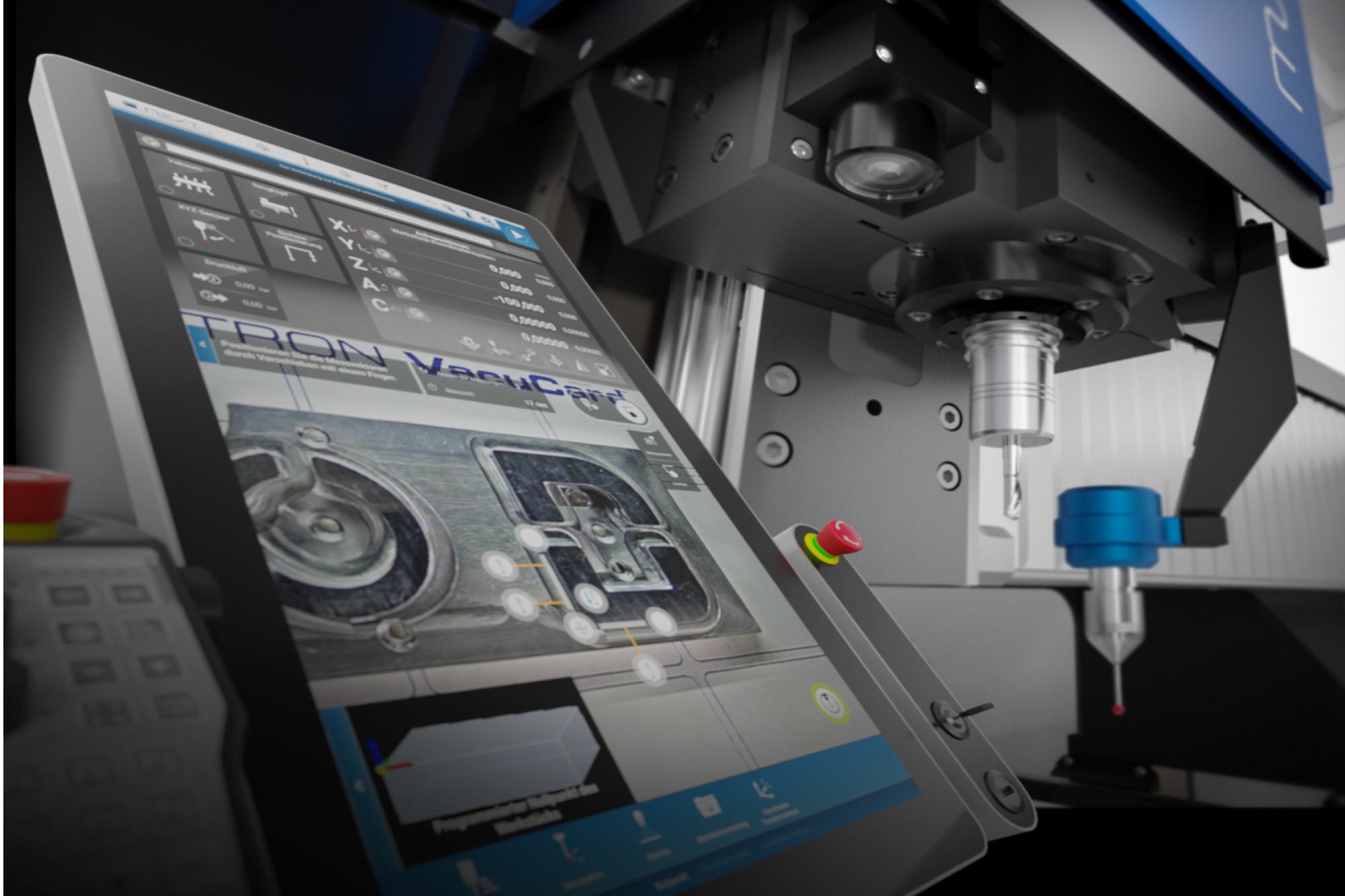

Daniel: Music is very integral for us. We are deeply intrigued by its connection to the vibration and techniques in machine tools. With the specialised algorithms, we can detect when the grinding wheel makes contact with the workpiece through these vibrations. Music creates the same vibrations, indicating its crucial role in our operations.

What sectors are currently showing growth in the global grinding business, and how is Studer reforming its grinding process?

Sandro: Our machine sales have spanned over 35 countries in the past year. The sales vary depending on the turnaround of the year. The aerospace and semiconductor processing sectors are experiencing growth. Global air travel is rising again, leading to increased aircraft purchases. This has provided a significant potential market for our grinding machines. This growth trend expands to all our counterparts as well.

How does machine weight optimise the damping system in grinding operations?

Daniel: The grinding process relies heavily on an effective damping system for optimal performance. Enhanced damping improves the stability and behaviour of the machine. This is crucial in grinding operations. So, we focus on increasing weight rather than reducing the machine’s weight to enhance its performance.

What procedures are undertaken to ensure on-time delivery after placing an order?

Sandro: We have one of the fastest delivery times globally. Our delivery timeframe for standard machines is typically every four to five months. It is even quicker for stock machines, with delivery possible within a few weeks. This rapid delivery gives us a significant advantage. Our extensive in-house manufacturing capability makes this further possible. The key components of our grinding machines, which are crucial for ensuring accuracy, are all produced in-house.

Daniel: It varies depending on the situation. We often need to navigate multiple loops of questioning to fully grasp the process, make informed decisions, and generate further inquiries. The complexity of the investigations also influences the duration.

India is advocating for ‘Make in India’ along with product assembly. How is Studer planning to leverage this situation?

Sandro: India is a crucial market for us. We experienced a successful past year there. We observed numerous promising projects and system machines in terms of value. Studer is eagerly anticipating the continued development and growth of the Indian market. We remain optimistic about the prospects in India and are keen to see further contributions from both our company and our group as a whole.

Daniel: We have our personnel in India. Studer still needs to collaborate with external technicians here in India. However, we are open to the possibility in the future. As of now, we do not have any ongoing projects or immediate plans. However, we are considering potential opportunities down the line.

STUDER always brings a lot of value to its products. What R&D efforts contribute to this in your core product offerings?

Sandro: We emphasise continuously developing new products and innovations. Annually, we introduce several new products. Last year, we presented S-100, a universal internal cylindrical grinding machine. We also unveiled the insert load and a new loading system and made history by introducing three distinct loading systems. This segment is substantial and is prime for our future endeavours.

How do you combine human expertise and machine capabilities to enhance your operational efficiency?

Daniel: The advantage we can achieve is by aligning the support provided by our team with the operation of the machine and the expertise of the individuals using it. Operators possess valuable knowledge that is above any machine. However, machines excel in speed and analytical capabilities, such as vibration analysis. Our goal for the future is to combine knowledge of both people and machines to enhance our capabilities.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.