IIoT: Transforming the manufacturing space

By OEM Update Editorial June 13, 2018 12:04 pm IST

Sameer Kelkar,

CEO, Grind Master

The early movers deploying IIoT to an advanced level are now seeing phenomenal rewards. They are now moving towards incorporating AI in controlling the network that has been created and get further.

Deploying IIoT earlier, results phenomenal rewards

IIoT is ready to transform the manufacturing space and bring new possibilities such as mass customisation. IIoT is being deployed in varying degrees by various companies. It is a paradigm shift, industry needs to understand and get deeper into the subject, while getting benefits of investments made. Sameer Kelkar, CEO, Grind Master informs, “The early movers deploying IIoT to an advanced level are now seeing phenomenal rewards. They are now moving towards incorporating AI (Artificial Intelligence) in controlling the network that has been created and get further. Certain IoT features have become a default for many equipment suppliers in the manufacturing industry. This is a very positive sign.”

He adds, “With the free flow of information generating Big Data, new challenges in information security, data management are now being addressed. Analysis of information is getting importance. IIoT is a developing field and the possibilities will continue to grow in the next few years.”

Automotive industry to drive IIoT adoption in 2018

Grind Master’s preparedness in the area of IIoTGrind Master is recognised globally for its NANOFINISH technology for automotive powertrain parts. As a supplier of mission critical microfinishing machines to automotive OEMs globally, Grind Master has been competing successfully with German and Japanese companies on technology. IIoT compatible machines have thus been developed in Grind Master since 7-8 years, with the NANOFINISH Control System platform.

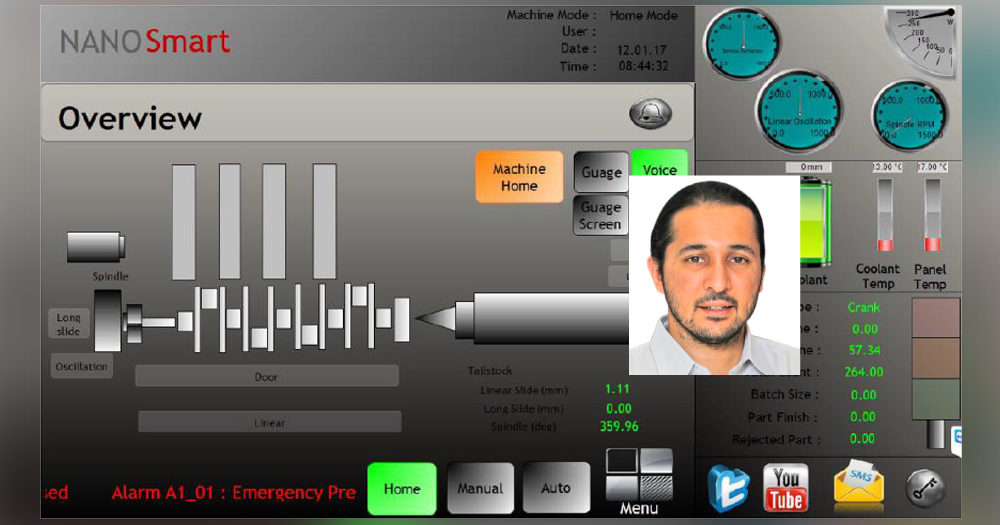

Recently, Grind Master upgraded its Control Technology to the NANOSMART Control System platform. This platform has a full range of features for the connected world. It provides quick access to the machine using the RAMS (Remote Asset Management System) platform and via mobile apps and CCTV cameras. The machine has enhanced ability to communicate through SMS, twitter, emails. For making troubleshooting easy there is voice guidance for operators in multiple languages. A plethora of sensors, energy meters, etc keep a tab on various functions of the machine and give continual feedback about the health of the machine.

Kelkar asserts, “NANOSMART Control System has been displayed in several exhibitions to a great response since 2017. Machine users have loved the system due to its versatility, performance and intuitive approach. Grind Master offers sophisticated IIoT features on its complete range of machines and robotic automation solutions.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.