IIoT is changing the way industries work

By OEM Update Editorial June 13, 2018 11:51 am IST

IIoT has become increasingly more pervasive in the context of industry as digitisation has become a business priority for many organisations, writes

Evolving technologies have shown many incrementally better and efficient ways of creating better products and solutions. The pace at which technological evolutions are happening is unprecedented. Often, we find ourselves with new technology, which not just surprise us but also give us the reason to believe that tomorrow is the future of new technologies. For a technology company, it has become mandatory to develop newer products and solutions.

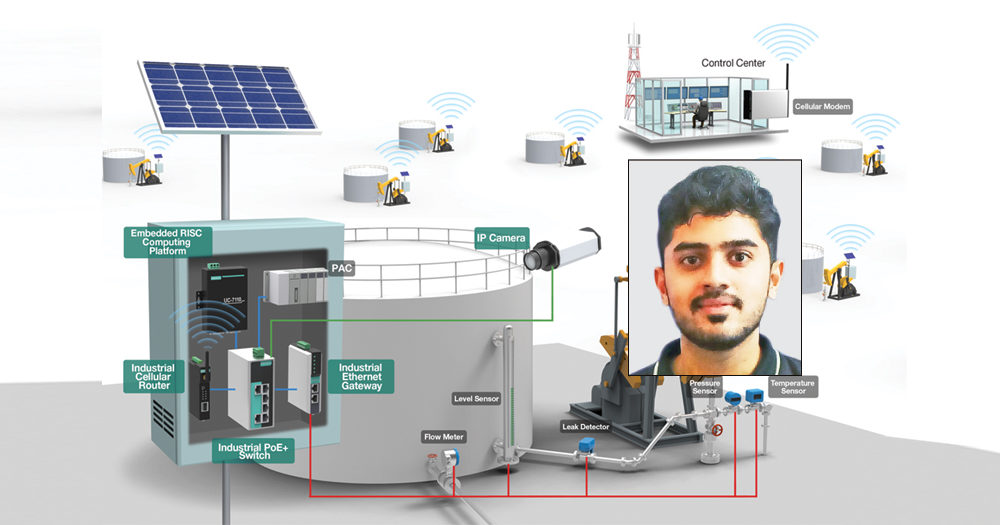

The Industrial Internet of Things (IIoT) is the physical devices, vehicles, buildings and so on that are connected via communications software to exchange, analyse and act on information, specifically in an industrial context. Together, these form part of what is referred to as Industry 4.0 or the fourth industrial revolution.

IIoT has become increasingly more pervasive in the context of industry as digitisation has become a business priority for many organisations. IIoT brings together brilliant machines, advanced analytics, and people at work.

These insights can then help drive smarter, faster business decisions for industrial companies. IIoT is changing the way industries work. Whether it’s enabling predictive analytics to detect corrosion inside a refinery pipe or providing real-time production data to uncover additional capacity in a plant or driving visibility and control over an industrial system environment to prevent cyber-attacks, driving powerful business.

The IIoT connects sensors to analytic and other systems to automatically improve performance, safety, reliability, and energy efficiency by:

• Collecting data from sensors (things) much more cost-effectively than ever before because sensors are often battery-powered and wireless.

• Interpreting this data strategically using Big Data analytics and other techniques to turn the data into actionable information.

• Presenting this actionable information to the right person, either plant personnel or remote experts, and at the right time.

• Delivering performance improvements when personnel take corrective action.

• Operational effectiveness: Drive growth, reduce waste, increase profits and improve efficiency for improved business performance.

• Real-time overall equipment effectiveness: Monitor and maximise line efficiency. Get real-time insights into OEE (Overall Equipment Effectiveness), OPE (Overall Process Effectiveness) at cell, machine and/or plant levels.

• Asset management: Go from reactive to proactive and predictive. Monitor performance and manage it remotely.

• Alerts and notifications: Set alerts and notifications to identify idle time pockets. Monitor tool and inventory consumption. Reduce spares and tooling costs.

• Energy monitoring: Get granular visibility into energy consumption at machine, cell and plant levels. With real-time monitoring for load management, identify downsizing opportunities and reduce network losses resulting in substantial energy conservation.

• Production visibility: With a connected shop floor, create a centralised platform – a ‘single source of truth’ for all operational metrics of machine utilisation, performance, quality, condition monitoring and energy consumption in real-time.

• Remote asset monitoring: With the connected products gain insights into the real world operating parameters of assets deployed in the field. Monitor the health of assets remotely and predict equipment failure. Improve service levels and revenue models.

About Bluechip

Bluechip Infocorp Pvt Ltd is an embedded product and solutions design company with a vision to convert customer’s requirement into the best products and solutions. We bring on table the right blend of technology, creativity and elegant engineering expertise to design and deliver cutting edge embedded products and solutions. Bluechip is the brainchild of an industry veteran with core expertise in Embedded System Design, System on Chip Design, Internet of Things, Industrial Internet of Things, Augmented Reality, Digital networking, Wireless Connectivity, Android App Development, Machine Learning, etc. It targets the industries like home automation, wearables, Industry 4.0, and smart cities.

Author

Jaydev Dave

IoT Application Engineer

Bluechip Infocorp Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.