Green practices and smart tech to recast manufacturing

By OEM Update Editorial June 5, 2024 4:32 pm IST

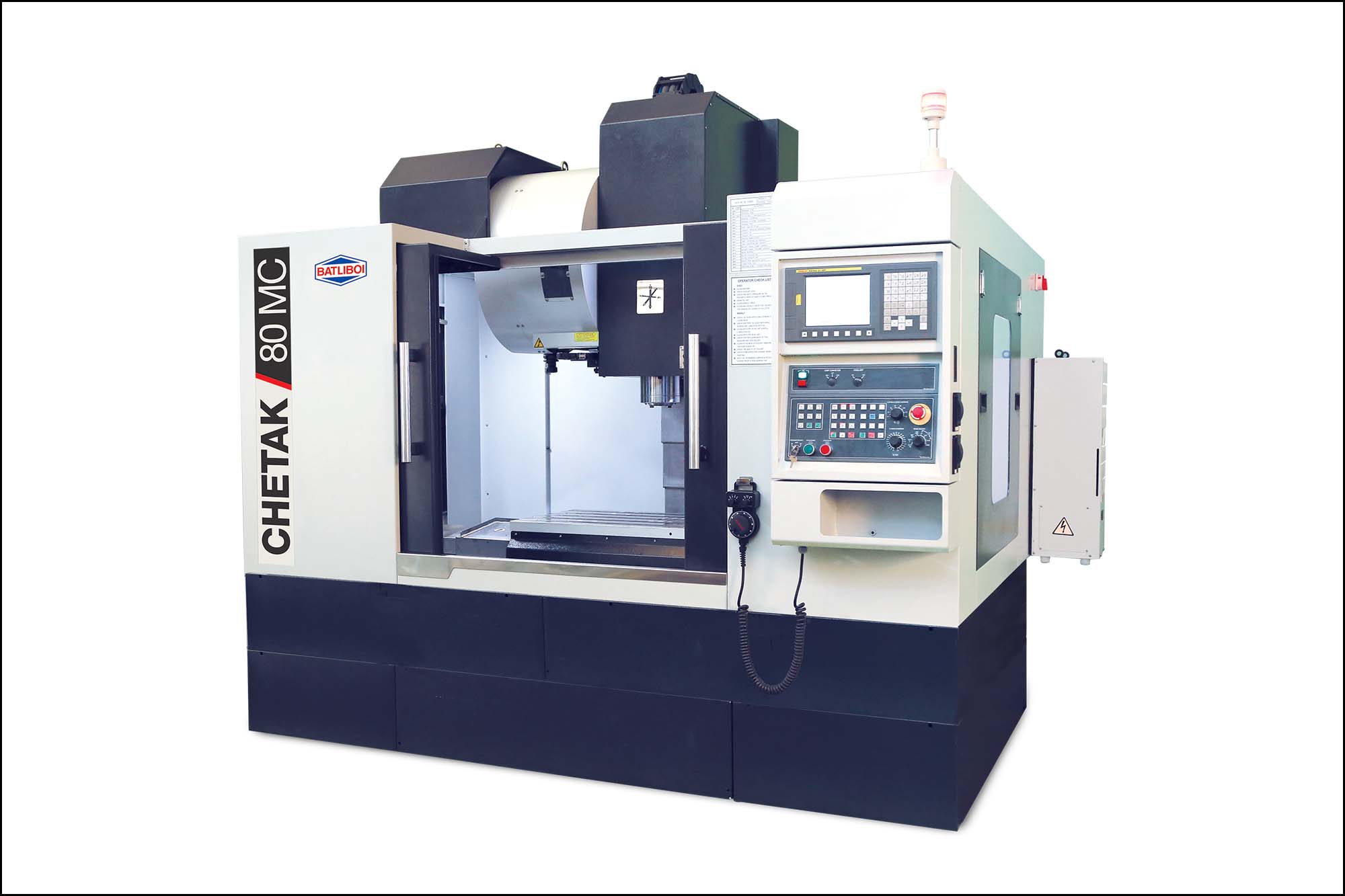

The metal cutting and forming industry looks promising with the integration of technology and increasing demand for precision and efficiency. Kabir Bhogilal, Executive Director at Batliboi Ltd., discusses the technological advancements in the machine tools industry and the requirement to update traditional manufacturing.

What are the recent technological advancements transforming the machine tools industry?

The machine tools industry is adopting advanced materials for tools and has increased the use of 3D printing for prototyping and additive manufacturing at scale to produce near-net shape parts. AI & ML in workflow automation technologies are leading the shift towards more sustainable practices in manufacturing. Innovations such as multi-axis machining and high-speed machining are enhancing precision and efficiency. Additionally, digitalisation and the Industrial Internet of Things (IIoT) are changing the dynamics of the industry by enabling predictive maintenance, real-time monitoring, and improved supply chain management.

What future do you see for the metal cutting and metal forming industry?

The future of metal cutting and forming looks promising, driven by technological advancements and increasing demand for precision and efficiency. Techniques like hydroforming, additive manufacturing, and advanced stamping and rolling are becoming more prevalent in metal forming. The industry is shifting towards greener practices by reducing waste and energy consumption. Smart technology integration will further enhance the capabilities and efficiency of metal cutting and forming processes.

What are the advantages of the Make in India initiative to scale up manufacturing?

Make in India is pushing manufacturing in emerging areas of high technology like aerospace and defence, industry 4.0, semiconductors, high-tech electronics, automobiles, electric vehicles, new materials and so on. The objective is to modernise the traditional sectors of manufacturing while exploring newer areas of manufacturing.The Make in India initiative provides several advantages for scaling manufacturing, including access to various government incentives, subsidies, and support for setting up and expanding manufacturing units. We witness improved infrastructure and logistics facilities that enhance supply chain efficiency and reduce operational costs. India readies a large pool of skilled and semi-skilled labour at competitive costs for global organisations.

Make in India provides enhanced domestic and international market access, promoting export opportunities for Indian manufacturers. Streamlined regulatory processes and policies facilitate ease of doing business and attract foreign investments.

How has Batliboi leveraged indigenous innovation and international collaborations to develop its range of machinery across its manufacturing plants?

We have leveraged indigenous innovation and international collaborations to develop a diverse range of machinery across our manufacturing plants. By fostering a culture of innovation, we encourage our R&D teams to develop homegrown solutions that address local market needs. This has been made evident by the launch of our new VTL 630 at PMTX, which was developed to cater to the needs of local customers. At the same time, we have established strategic partnerships with global technology leaders to access cutting-edge technologies and best practices. This approach ensures that our products are both competitive and aligned with global standards, enabling us to meet the evolving demands of our customers.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.