DMG MORI promotes digital workflows

By OEM Update Editorial June 12, 2018 4:35 pm IST

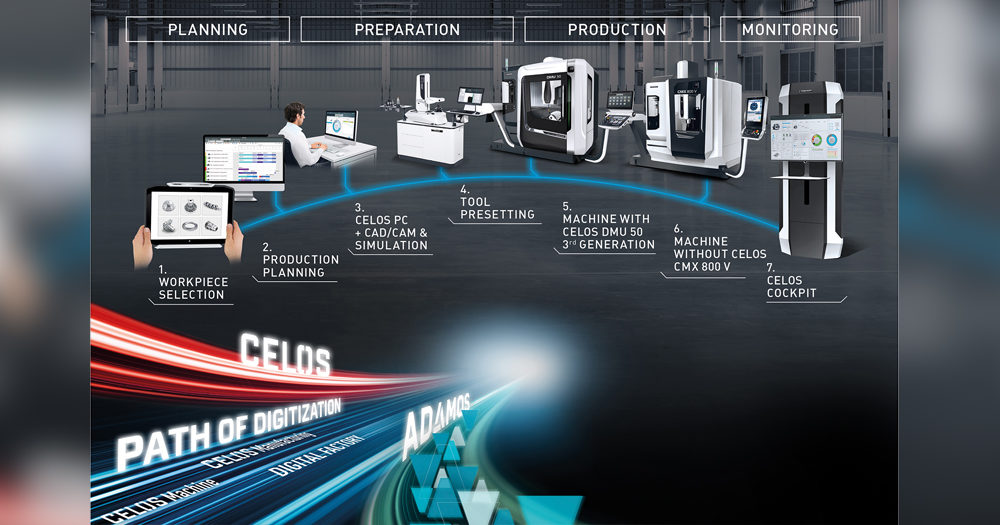

Industry 4.0 remains the dominant topic for machine tool manufacturing. In the process, DMG MORI is developing dynamically into a global turnkey partner. CELOS offers a modular portfolio of solutions for the integral digitalisation of the factory – of machines, processes and services.

Digitisation from one success to the next

For Dr. Holger Rudzio, Managing Director of DMG MORI Software Solutions, the workshop is the central focus of all digitalisation. The greatest advantage from his perspective: Digital transformation can take place step by step, meaning “bottom up” rather than “top down” – from machining processes through digital workflows to integral networked digital factories. One project after the other – and from one success to the next!

“Tool box” of digitalisation for small and large

The perspective is reflected by the “Path of Digitisation”, which DMG MORI has declared to be their overall guiding principal for themselves and their customers. A guiding principle that has enormously increased in importance with numerous digital innovations and future projects. Commencing in January, customers can experience “Digital Factories” with live demonstrations of the benefits of horizontal networking in DMG MORI showrooms. A “digital tool box” has been created at DMG MORI from all these innovations and future initiatives. This will enable smaller businesses to take advantage of a simple and harmonious entry point into digitalisation as well as serve larger companies as an integrated and modular system.

Fully digitalised workflows

From spring 2018, the focus will be on integrated digital workflows with CELOS Version 5.0 – from planning through production planning right up to monitoring. The CELOS APP package “Digital Planning” enables one to efficiently organise job orders, while taking into account various dependencies. The CELOS Production Planning app offers users a decisive plus when it comes to increased efficiency and reliability on the shop floor. Specifically, this covers the integral connecting of ERP systems, digital production planning and terminal-controlled factory production. “In combination with production planning, the consistent integration enables continuous process optimisation,” explains Dr. Rudzio. In turn, this reduces setup and idle times and increases productivity for the long term. The increased digital transparency should ensure increased planning reliability.

“Digital Tooling” is another workflow package. All of the tool information necessary for the production process can be managed centrally with this CELOS APP: during NC programming and simulation, and even during tooling, reading and loading. In the process, tool data can be accessed by various systems at the same time. All process-related data is stored in a central tool management system, making the history of a tool transparent and fully traceable.

Monitoring with additional benefits

The app package “Digital Monitoring” visualises all important information in the digital factory for more transparency during production. The CELOS Condition Analyser app offers recording, saving, analysis and visualisation of machine sensor data. The CELOS APP then makes it possible to analyse one or several machines, e.g. for early detection of machine problems. The Performance Monitor visualises current machine availability and efficiency, independent of the site. The CELOS APP thus offers transparency and monitoring options for basic production parameters – the so-called key performance indicators (KPIs).

Everything at a glance

The CELOS COCKPIT serves as the interface between all machines in the production environment. All information relevant to the workshop both from DMG MORI machines as well as external factories come together here. Users can gain an overall overview of the status of the shop floor – and, with the corresponding digital workflows from DMG MORI, even get information on orders and faults (including bottlenecks, waiting times, causes and remaining run-time periods).

With CELOS Version 5.0, all DMG MORI machines with Siemens, Heidenhain and MAPPS controls (with the exception of the SLIMline machines) will be available with CELOS Version 5.0 from April 2018. Existing machines with older CELOS versions can be updated to the latest software.

The CELOS Version 5.0 update is performed using an “update stick” and is carried out by DMG MORI Service. The data and communication settings remain completely intact. Every customer is provided with basic training on the new features during start of operation.

With ADAMOS to a turnkey provider

DMG MORI has implemented an important element of the CELOS digital factory with the digitalisation of the shop floor. To further expand digitalisation, DMG MORI, together with partners from mechanical engineering and IT, has founded the ADAMOS IIoT initiative.

“ADAMOS is an important component of our ‘Path of Digitisation’, as we have more control of the digitalisation process and are in a position to actively shape it,” stresses Dr. Rudzio on the strategic importance of the IIoT initiative. While DMG MORI independently develops a platform-based business model, ADAMOS GmbH cooperates in the area of the required IIoT infrastructure, on the basic software and digital products as well as the availability of data-based services.

CELOS Production Planning for enhanced planning and schedulingHighlights

• Intelligent planning tool for production

• Higher transparency for improved adherence to deadlines

• Optimisation of throughput times and batch sizes

• Visualisation of capacity reserves

• Planning of maintenance

• BDE/MDE feedback

• Interface for transferring orders from ERP systems

CELOS Digital Monitoring – The complete production process at a glance

Cockpit

Visualisation of relevant machine data from the CELOS Messenger, Condition Analyser, Performance Monitor, Production Planning and Tool Analyser Apps

Messenger

Increase in productivity due immediate detection of downtimes

Condition Analyser

Recording and analysis of machine data with direct feedback for maximum machine productivity

Performance Monitor

Recording, analysis and visualisation of machine availability and efficiency based on direct feedback from production, irrespective of the site.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.