The challenge of thin sheet welding in mechanical engineering

By Staff Report November 13, 2024 7:05 pm IST

Welding with the Fronius TPS 320i is exceptional as it enhances handling, welding processes, and functions.

Knoll Maschinenbau GmbH in Bad Saulgau, located in the heart of Germany’s Upper Swabia, enjoys a leading position due to its technology, quality, and brand awareness. The Swabian family business creates added value for all companies that machine metal in the automotive industry, energy and medical technology, machine and plant construction, and aerospace sectors.

High Real net output ratio

The advanced solutions optimise the performance of many machine tools. In addition to resource-conserving cooling lubricant cleaning systems, chip conveyors and pumps, the product range also includes central systems, which are individual pieces of equipment linked to form one system. They are needed to fully automatically transport chips and cooling lubricants to central processing plants. Automation solutions for assembly lines and intralogistics are another mainstay for Knoll. Examples include assembly conveyor belts, automated guided vehicles or cobot solutions.

Joachim Riebsamen, Shell Construction Production Manager, says, “As a solution provider, we offer all the necessary services from a single source: from project planning and manufacturing to commissioning and service. We believe that good customer relationships depend on transparency and trust. That is why we do not just rely on a website, brochures and sales pitches. In-house machining allows us to convince potential customers about the advantages of our products using real operations.”

Due to the high Real net output ratio, Knoll significantly reduces logistics requirements and all associated CO2 emissions in a cost-effective and sustainable manner.

The challenge of thin sheet welding

Many components get welded by hand in shell construction. Sheets with different wall thicknesses up to 25 mm are used during this process. The Knoll experts mainly use S355 steel, joined with the shielding gas M21 (82% Ar/18% CO2) and the wire additive SG3 (G4Si1) for the coolant cleaning and conveying system. The company’s WPS (Welding Procedure Specification) provides the basis for parameterisation.

Holger Kleck, foreman in the welding technology section, explains, “One of our biggest welding challenges is the processing of thin sheets. Our components have a material thickness of 1–6 mm and warp relatively quickly. So, we have to use low-warpage welding with little heat input. We often manufacture visible parts that need to be perfect from a metallurgical perspective and need to have seams that look good. We want to avoid uneconomical reworking in these areas at all costs. As a result, we mostly need spatter-free welding with a low seam build-up. The Fronius TPS 320i welding machine offers the best solution for all these requirements.”

Knoll’s experts rely on pulse welding to join thin sheets, known for minimal spattering and distortion. The TPS 320i’s intelligent MIG/MAG pulse synergic function provides a controlled material transfer during welding. The base current phase reduces energy input, heating the workpiece surface steadily. In the pulsing current phase, controlled current pulses detach droplets accurately, ensuring precise, low-spatter welding. Unwanted short-circuits and spatter are eliminated, aided by the SFI (spatter-free ignition) feature.

Kleck adds, “When pulse welding with the TPS 320i, the arc remains stable even at low amperage. If we need rippled seams, we can use the SynchroPuls function, in which the welding power changes cyclically between two operating points. All in all, our long-standing partnership with Fronius has allowed us to optimise our welding processes. We will continue to rely on the Austrian company in the future. The welding machines are advanced and easy to maintain. If we need support, we do not have to wait long.”

TPS 320i: the welding machine that uses clear language

Over 70 manual welding workstations at Knoll are equipped with advanced welding machines. They are easy to operate due to a customisable 7-inch touch display, penetration and arc length stabilisers, and the fact that they can be expanded with task-specific software packages known as Welding Packages. Examples of this include LSC (Low Spatter Control), PMC (Pulse Multi Control), and CMT (Cold Metal Transfer). Welders can log in with their own NFC card and access their authorisations and settings.

The menu navigation is available in over 30 languages. The welding machine’s display is multilingual and uses clear language. Detailed descriptions and graphical animations provide welding specialists with a step-by-step guide to resistance alignment. The TPS-320i variant used with an integrated wire feeder is ideally suited for welding tasks to be carried out manually.

All parameters at a glance

The welding machine is operated with a central rotary push-button and a touchscreen. The specialists can see and adjust all the relevant control variables on the TPS 320i’s central display. Innovative animations support the welding specialists when entering parameters. For example, there is a graphical representation of how dimensions change as arc length corrections are made, depending on whether a positive or negative correction is entered.Easy jobs and WeldConnect App

The machine responds perfectly even if the operation is affected by welding gloves. Recurring parameter combinations for specific tasks can be saved as personalised easy jobs at the touch of a button. The practical Fronius WeldConnect app for Android and iPhone helps set the welding specifications. As soon as the base material, filler metal and shielding gas are scanned using a QR code and the weld seam profile, material thickness, welding process, and welding position have been entered on the mobile phone, the welding specialist can use NFC (near-field communication) to transfer the calculated values to the TPS 320i or to a mobile phone belonging to another employee, who in turn transfers them to the welding machine.

Robot applications

Welding job is quite demanding, at least when robots come into play. Then, in addition to welding knowledge from electrical engineering to metallurgy, programming skills are also required. There is a huge demand for welding technicians who know how to program robots.

Many companies, including Knoll, now create welding programs offline to minimise downtimes. It also offers the advantage of welding simulation on the digital twin. In this process, the software identifies axis limits, calculates starting points, limits positions and journeys, and sets teaching points independently.

Obstacles are visualised , and welding torch positions are corrected on time before the first weld is over.

Knoll now also uses a cobot system. The weld path and sequence are calculated by the software, recorded, and are permanently available for later jobs. The system at Knoll uses CMT technology. Due to its stable arc combined with reduced heat input and low spattering, today’s renowned “cold” MIG/MAG welding process from Fronius is used worldwide in plant, machine, power plant and automotive construction, in aircraft and food industries, and medical technology. It plays to its unrivalled strengths, especially for thin sheet welding.

Kleck says, “Operating cobots is intuitive and has a certain fun factor. This is especially true for young welders. They think cobot welding is cool, as it is as easy as using a smartphone. Anyone familiar with a smartphone can operate a cobot within a few hours. If this is enclosed and equipped with a fume extractor, the welding specialists are protected against unhealthy welding fumes.”

Health and Safety

Knoll uses ergonomic workstations and the best possible personal protective equipment. All welding tables are height-adjustable, and automatically darkening welding helmets plus fresh air supply have long been standard. In addition, the room air is exchanged four times per hour.

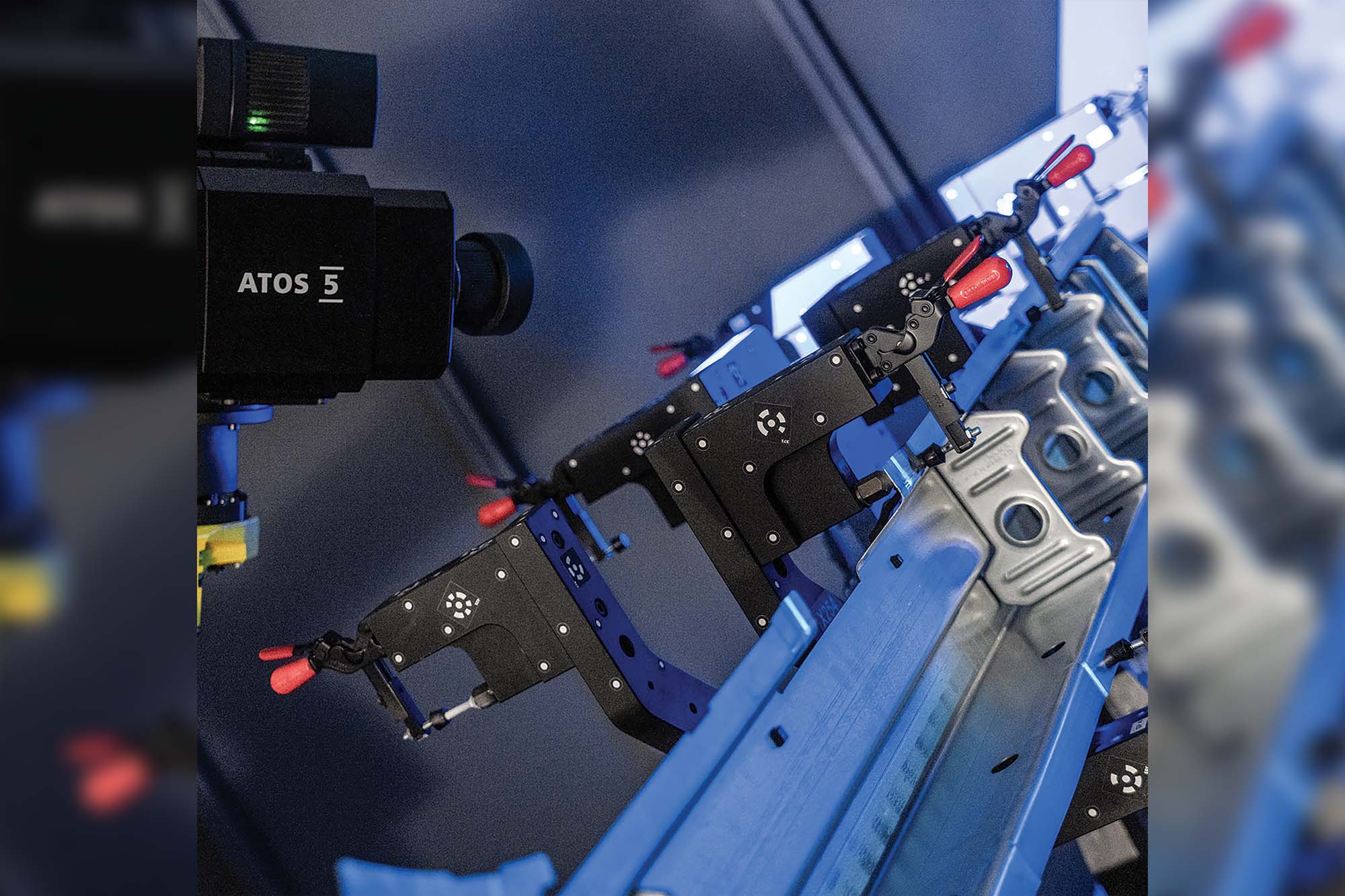

“Workplace ergonomics is an important topic,” Riebsamen explains. The component safety and quality also play a crucial role. The experts at Knoll apply various testing methods, such as dye penetration testing (PT), to check each component. The minute errors not visible to the naked eye can be traced with PT and corrected by the welding specialist.

In line with its Motto, “It works,” Knoll Maschinenbau GmbH supplies its customers with reliable, easy-to-operate individual plants and systems.

For more information, contact at marketing.india@fronius.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.