AI, Big Data & 3D Printing to be the game-changers in industrial revolution

By OEM Update Editorial June 9, 2021 12:19 pm IST

Industries must consider automating the whole set-up, right from procuring raw material to the final output delivered.

Discussing the vital aspects of 3D printing in Indian industries, Swapnil Sansare, CEO, Divide By Zero explains how 3D printing, AI and automation can realign the consumer behaviour towards Indian industries.

Indian industries have embraced Industry 4.0 and its technologies to carve a bright future of Indian manufacturing. With this level of acceptance, how ready are we to accept Industry 5.0?

Industry 5.0 talks about complete automation supervised by trained robots. Even though Indian industries are running distributed manufacturing systems on many levels, we can’t ignore human supervision right now. We need operators who would be responsible for changing the tool per se or remove the component and even load new materials.

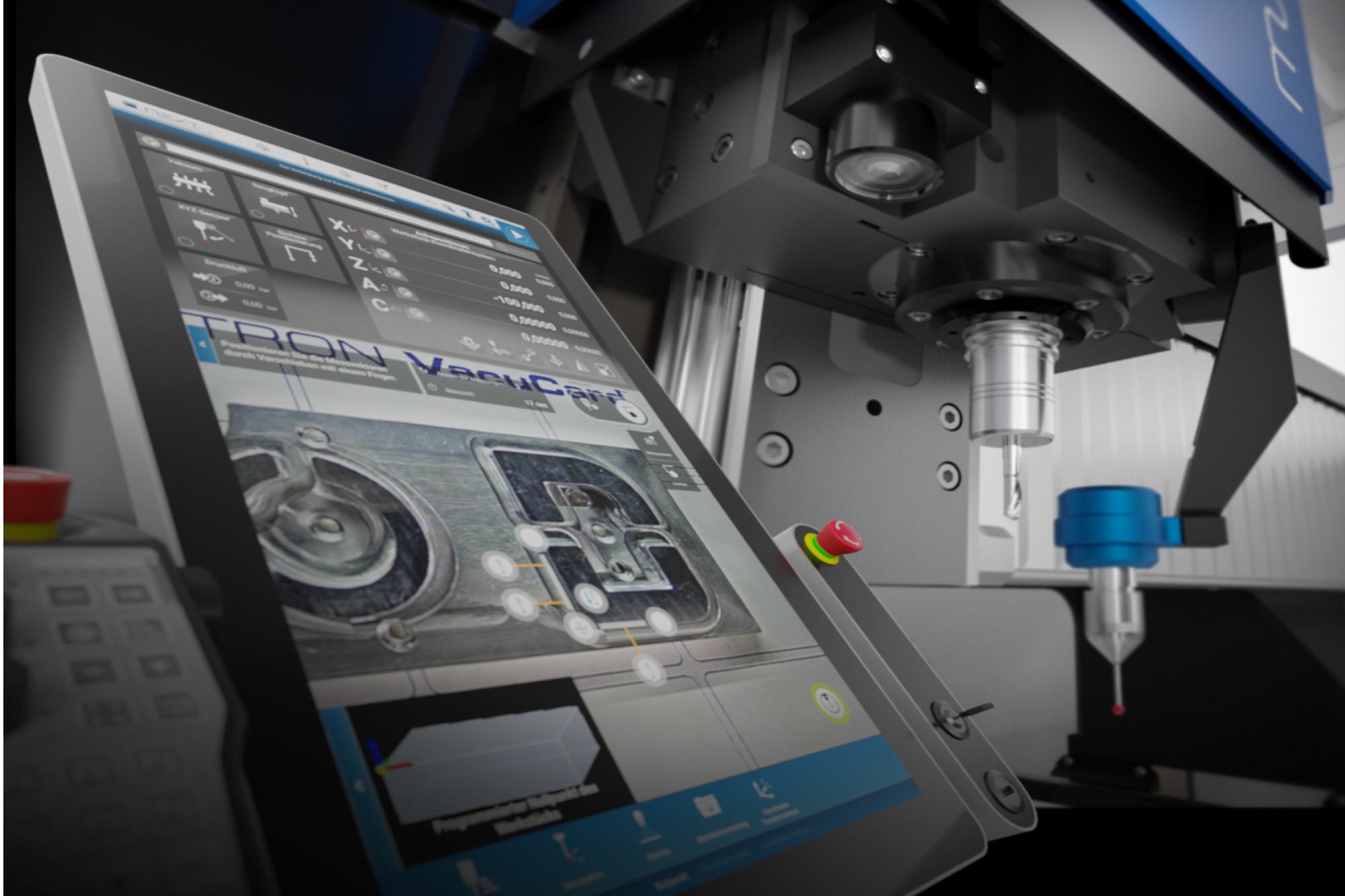

India is slowly evolving through the industrial revolution phase to reach Industry 5.0. Big data and AI are coming together in analysing tool dimensions, accuracy and precision issues to generate corrective measures tackling unforeseen circumstances without human supervision.

With 3D printing, industries can deliver critical components on-demand without involving third-party vendors at all. Not just that, operators can function these printers online sitting anywhere across the world with the highest standards of built-in security features.

India is ready to leap forward and reach the Industry 5.0 stage. However, we need more hardware and software support to completely calibrate machines with robotics using AI.

With the advent of 3D Printing, AI, robotics, connected data enterprise, what are the major areas where the industry witnessed transformations and business prospects?

The major area where we as an OEM witnessed over the past several years is predicting the demand forecast well in advance and plan our supply chain accordingly. AI and Big Data can align together in predicting the needs and requirements of customers based on consumer purchase behaviour. With the demand forecast ready, 3D printers close to the demand sites can deliver complex components in just a couple of days. The best part of 3D printing is that its operators can function sitting anywhere across the globe with the highest standards of built-in security features.

Besides, 3D printing is helping companies to reduce their warehouse carrying costs for small-batch custom parts by over 90 percent as the complete manufacturing process is done just in time. As a result, industries need not stock their components saving them huge warehouse carrying costs.

Last but not the least, 3D printing and AI is empowering industries to stay independent from third-party vendors. This is proving to be a game-changer altogether wherein companies don’t need any vendors from raw material procurement to machining the tool and eventually transporting that to the final delivery site.Collaboration of humans and machines (robots and cobots) are expected to play a key role in carving India’s future. How do you see India’s future with Industry 5.0?

The automotive industry plays a pivotal role in driving world economies. It is, however, slowly evolving itself by going through a gradual change towards becoming completely EV.

These new generation vehicles demand different motion systems and powertrain protocols. Consequently, they will need a lot of critical vehicle components on-demand. To meet these demand forecasts, India will have to opt-in for cobots and robots to ensure the delivery of quality products, eventually becoming a global hub for manufacturing.

Indian industries have already accepted 3D printing and believe this when we say, robots, cobots, AI, Big data, and 3D printing will play a game-changing role in taking India to the next Industrial revolution.

What are the challenges for the SME and MSME sector in adopting factory automation, digitisation and robotics for efficient manufacturing processes?

Some of the key areas that industries are currently dealing with is training and development of human resource and keeping them motivated to scale up their skills as and when the market demands.

Additionally, running a full-fledged automated digitised robotics factory will require huge capital investments, manpower, supply chain, and operational costs. Hence, industries are in dire need of automating the whole set-up as much as possible, from raw material procurement to final product delivery.

Not just that, in a highly competitive market, it is really important to keep fixed expenses as low as possible.

However, countless OEM manufacturers, including 3D printer manufacturing houses, have opened the doors to lease out their state-of-the-art machineries on long-term contracts to reduce cash burdens.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.