Oil condition monitoring for mechanical maintenance; Minimum down time leads to maximum revenue

By OEM Update Editorial October 12, 2021 12:23 pm IST

Mechanical maintenance personnel are fully aware about the importance of Lubricants and Lubrication of machines, and the role of lubrication in mechanical maintenance in Industrial Plants.

Oil in a machine is like ‘blood in a human body’. Hence, every care has to be taken that only clean lubricants (oils or greases) are fed to the machines. It has been the experience of oil company technical services executives and several maintenance personnel at plants that oils and greases get contaminated during storage, handling and dispensing-before oils or greases are fed to machines.

This is due to the exposure of oil barrels to “breathing action”. During day, due to sun heat directly falling on barrels they expands the oil content in the barrel and pushed the air over the oil head to outside environment due to the oil cubical expansion, and during night the same oil get contracted due to colder and moist environment leading to suction of air along with moisture in air and environment micro dust. When barrels are kept outdoors for over a month, this breathing action of barrels will contaminate the oils in the barrels. This “fresh contaminated oil” when fed to machines, leads to mechanical damage in machines.

Hence, the first step to start the process of ‘Proactive Mechanical Maintenance’ starts from good storage, handling and dispensing of lubricants. It is suggested that the oil and grease barrels are either stored indoor under good housekeeping or under shed covered storage (if indoor storage is not possible) where sunlight does not directly fall on barrels.

Under outdoor storage the direct heat of the sun falls on oil or grease barrels. Grease barrels when stored outside for a period of 30 days or more, there shall be oil-soap separation leading to grease becoming off-specification and unfit for use.

Hence, the first step to good “lubrication practices” is to ensure feeding clean oil and good quality grease to machines. Rest assured the mechanical maintenance cost will be reduced considerably. This is the basic step for proactive mechanical maintenance. Therefore, in order to establish proactive maintenance, it is necessary to ensure the following.

These are the important and simple steps required to achieve proactive mechanical maintenance.

- Keeping all lubricants, especially greases indoor under good housekeeping – as when lubricants (including greases) – do get contaminated or off-spec if stored outdoor for over 30 days at the site storage.

- Testing oils and greases regularly. Oil test report available within 48/56 hours, otherwise mechanical damages will set-in, in the machines – hence, it is important to have oil testing facilities at site or near the site (in order to get oil test report within 48-56 hours of the oil sample taken.

Recommended oil sampling intervals

- Oil testing laboratory at or near the site is the very basic need to introduce “Proactive maintenance”. Oil test reports must be available to the maintenance team within 48 hrs failing mechanical wear/damage starts setting-up in the machine. Regular (monthly) plant audit of lubrication practices is useful in improving the maintenance and reducing the mechanical maintenance costs. This cost in many plants is not monitored and hence remains unnoticed. Once a system to monitor the mechanical maintenance costs is introduced, it could be an eyeopener.

- The main emphasis should be on clean oil or greases being fed to machines and lubrication schedules being met on a daily, weekly or monthly basis.Has oil testing schedules machine-wise have been made and targets being met on a month to month basis.

Proactive maintenance leads to an increase in life of costly machines, which are high value fixed assets.

Therefore proactive maintenance will add-value to mechanical maintenance and cost reduction in the plant operations and improve reliability. Oil analysis is a key to machine condition monitoring

Quantifying benefits of oil analysis

The application of oil analysis reports will lead to improved maintenance activities, and produce benefits to the organisation. Often, oil analysis thinks only in terms of the savings associated with extended or condition-based oil changes. They often fail to capture value contributions related to equipment reliability visible through wear metal analysis. Effective management of lubrication and oil analysis builds reliability into the system.Oil analysis produces tremendous value when it provides advance warning of machine failures.

The early warning system allows plant management to schedule the maintenance activity to avoid sudden interruption of production, and to have required machine parts and labor lined up.

Below is a summary of some of the costs that can be controlled when decisions are made with the oil analysis reports.

- Downtime Costs – Maintenance team can calculate the typical downtime cost associated with a machine’s failure and multiply it by the average duration of the lost production time. It is important to look only at the profit of the production in the financial analysis.

- Costs of Lubrication – Oil analysis reduces the consumption of lubricants. Change oil if needed, and not on the number of hours used in the machine. Savings estimates should include lubricant costs, labor and disposal costs.

- Energy Consumption Costs – Usually, improving lubrication and feeding clean lubricants are involved in reducing friction. By comparing energy consumption during normal operation before and after the changes with an amp meter, these savings can be effectively estimated.The clean oil or grease shall reduce friction between two moving surfaces and reduce energy consumption.

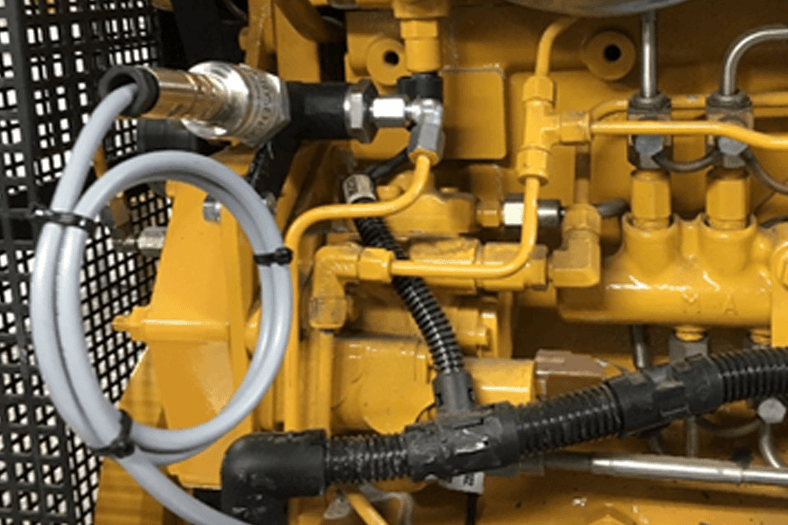

- Product Quality Costs – This is especially true in applications like mining machines (having sensitive hydraulic systems), molding, machining, rolling and casting where the precision of hydraulic control is affected by the lubricant’s quality. But it is true elsewhere too.

- Increased Production – Well lubricated machines can produce more. For example, contamination (Dust, dirt, wear metals, moisture / water) or varnish can slow the cycle time of a machine, reducing its output. Likewise, proactive and predictive lubrication analysis and management may enable management to turn production up with greater confidence that reliability will be assured.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.