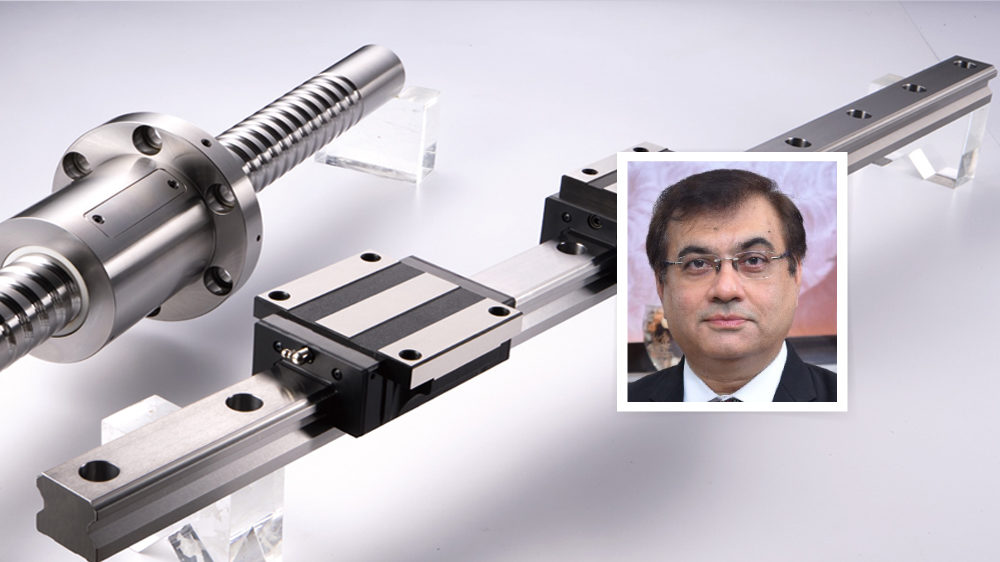

Superslides: Leading the linear motion products and ballscrews field

By OEM Update Editorial August 10, 2018 5:04 pm IST

PMI -Superslide is also trying to offer cost effective solutions so that our India customers can adopt new technologies at the earliest time with affordable price.

Rajiv Desai, Managing Director, Superslides & Ballscrews Co. India Pvt. Ltd.

Superslides & Ballscrews Co. India Pvt. Ltd. is one of the prominent company to have achieved a good name in the field of linear motion system in India, for its quality and services. In an interaction with OEM Update, Rajiv Desai, Managing Director, Superslides & Ballscrews Co. India Pvt. Ltd. Speaks about the company’s journey and future plans.

Superslides & Ballscrews Co. India Pvt. Ltd is counted as one of the recognized firms for linear motion products and ball screws. Can you walk us through the company’s journey till now?

Superslides was established in 1999 and have expertise in the field of linear motion & transmission technology and represents Precision Motion Industries, Inc. (PMI), Taiwan, who are globally leaders in linear guideways & ballscrews manufacturing.

As Japanese & German manufacturers were always the first choice of India, we had a tough time convincing the Indian machine tool manufacturer to accept a Taiwan make. In 2004, when the manufacturing sector started booming with many applications along with CNC machine tools such as automation, robotics, printing & packaging, material handling and so, there was a high demand of linear motion products across the world and it was a challenge to get these products in make; post that the Indian users started accepting the PMI brand.

PMI has high end manufacturing facilities with stringent quality checks and hence, the offered products have the same accuracy and life cycle as any other Japan or European brands. Our customers never felt the need to compromise while using PMI products. Now, currently we occupy more than 40 per cent market share of Indian machine tool consumption which has a recognition of PMI – Superslides brand.

Tell us a bit about your range of products? Which industries do you cater the most?

Superslides product range consists of linear motion products, ballscrews, linear actuators, precision locknuts & locking elements, rack & pinion, gear-box and custom-made X-Y slides & assemblies.

SUPERSLIDES specialises in providing all kinds of solutions for ballscrews & linear guideways.

PMI ballscrew range consists of precision ground zero backlash ballscrews in single & double nut, miniature ballscrew, internal & external circulation ballscrew, hollow shaft cooling ballscrew & nut cooling ballscrew, D-type high speed ballscrew for high rapid which requires for VMC, ballscrew with ceramic balls for extremely high positioning accuracy. SUPERSLIDE also offer rolled ballscrews for moderate accuracy applications such as printing machines, packaging machines, industrial automation which includes pick & place, dispensing equipment, transfer lines, robotic arms etc.

Linear guideways are widely used components, which is required for smooth & silent linear movements while taking heavy top, reverse & cantilever force. PMI has a range of all sort of ball & roller guideways which are mainly used in machine tool & CNC machines, stainless steel miniature guideways for medical & testing equipment, cage type guideways for robotics & clean room applications, wide type flat guideways for pallet changer and tool changer equipment.

What makes your products stand out from your counterparts? What procedure do you adopt to assure superior quality?PMI products are made of German raw material (steel), manufactured on high accurate Japanese Mitsui-Seiki grinding machines, sub-zero treatment of each linear block & ballnut, and stringent quality control with laser inspection. These make the PMI product very accurate, reliable with long working life.

PMI in Taiwan constantly upgrades their manufacturing technology to support critical applications in defence, aviation & nuclear fields.

Some of our major Indian customers are LMW, ACE Designers, AMS, BFW, HMT, JYOTI CNC, MICROMATIC Grinding, MACPOWER CNC, COSMOS,

L&T, GODREJ & BOYCE, Indian Railways, BHEL and more.

How do you validate the company’s contribution towards the automation and welding industry?

Welding automation is one of the fastest increasing segment because of the expansion of Indian automotive industries. We have several customers who provide complex automation & robotics solutions to automotive and their ancillary & component manufacturers. We support these customers by giving our expertise solutions which help their user to get higher production with constant accuracy along with great safety measures.

What industry challenges do you face?

Indian manufacturing segment is rapidly growing but simultaneously also under steep competition with China, Japan & Korean manufacturers. India, having the second largest mobile phone user population, still depend on foreign-made handsets. Indian manufacturing segments need to upgrade its production processes and needs to adopt automation for mass production to make the Indian products competitive in price & quality.

PMI -Superslides is also trying to offer cost effective solutions so that our India customers can adopt new technologies at the earliest time with affordable price. We have recently launched our headquarters in Navi Mumbai which is equipped with all modern amenities, large inventory and also offer repair & after sales services very effectively.

We at SUPERSLIDE accepts challenges to support our customers with quick supply & service and are committed full heartedly.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.