Machine tool market is expected to exhibit CAGR of 11-13%

By OEM Update Editorial June 16, 2022 4:44 pm IST

Industry 4.0 and 5.0 is definitely required and most of the industries have started following it and practicing it

Sanjib Chakraborty, Managing Director, Hurco India Pvt. Ltd. in an Interview with OEM Update

Sanjib Chakraborty, MD, Hurco India talked about growth for CNC machines and product range stating that Hurco customers are using various innovative software features, which ensure Industry 4.0 to happen.

Latest trends and innovation impacting the machine tools industry

In current times of digital adoption, the challenge is that how fast and how better you can do the components, however, the machines were used to do the components earlier also. The accuracy levels are at a very close tolerance andalso the complex machining parts are coming up. In the coming days, we have to have a technology which can take care of machining challenges. Furthermore, different types of materials are coming up. Nowadays, Inconel, Titanium, SS and their alloy are also shaping up. New machining challenges are emerging. So, machine tools should have the up-todate technology with innovations to take care of the expectation of such machining process.

Hurco products and solutions

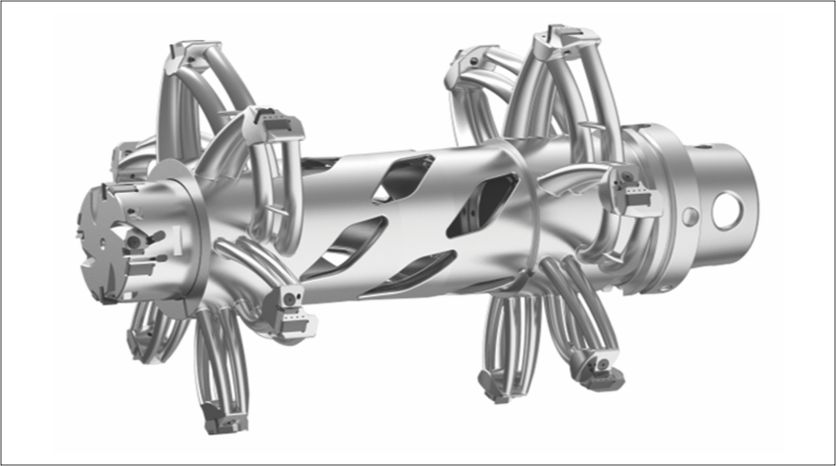

HURCO is a 54 years old technology company. Being a technology company we are committed to our investors. And our R&D is continuously working on innovations on Motion Control to ensure that our customers should get maximum benefit out of this technology. Our main objective of innovation is to make technology affordable and adaptable across the industry, from the smallest customer to the largest customer. In our product range, we have machining centre upto five axis machines. In turning centre, we are having multi-axis turning centres. And in five axis, we have all the types of configuration, right from Trunnion to Cantilever type and Swivel Head. Besides that we have VMC, we have Boring mills. The most important design feature for all the machines is for batch quantity. That means High mix – Low volume.

Five axis CNC machine tools

is using 5 axis machines even for 3 axis components to be competitive. It helps customers to get better productivity, better accuracy and better tool life and machine life. So, today we are seeing very good market requirements for Five-axis machines and day by day it is increasing. Our core technology i.e. the controller that we have, is a five axis compatible controller.This controller can do the entire five axis machining in a much easier way and much more accurately. 5- axis programming is a bit complicated as it is not easy for operator to visualise the complex tool path. Hurco controller helps operators to program the machining process much easier and faster compared to other standard controllers.

Growth for CNC machine centres

India is going to be a global hub for manufacturing. In last few years, it has been observed that manufacturing is shifting from China to India. So, once India becomes the manufacturing hub in its truest sense; whether it be automobile or aerospace or medical implant or valve industries, there will be a lot of development and growth will definitely be seen. So, we are expecting that the machine tool market in India will be moving on an average of 11- 13%. This is a good fortune for our machine tool market.

Digital manufacturing to optimize productionDigital manufacturing is persisting for many years with Hurco. Though, in India it became increasingly popular in last few years, especially during last Pandemic. But globally, Hurco customers are using various innovative software features, which will ensure Industry 4.0 to happen. Monitoring and

Machine tool market is expected to exhibit CAGR of 11-13%

recording the process data is very easy on Hurco machine. It is very easy to interface the machine with simple automation. Hurco engineers can take the access of the machine remotely to diagnose the problem and to give the solution remotely. Similarly, Hurco customers can access the machine to monitor the performance of the machine and the operator. So, these are all available with Hurco. Industry 4.0 And 5.0 is definitely required and in my opinion, most of the industries have started following it and practicing it. It is now easier for Hurco customers with various innovative and user friendly software.

Innovations desirable in machine tool industry

We need automation, digitalization and remotely manageable machines. We also need technology with faster data processing features and accurate motion control. The processing time from print to parts should be faster and very accurate. For that, the Hurco software can play a big role. Our customers can do conversational programming without G and M code for any types of 2 D components. Nowadays, our R & D is working on conversational programming for 3D profiles, so that the dependency on 3rd Party CAM software can be minimised.

Innovative measures leading to expansion of manufacturing unit capacity

Automation is one of the things where we have to focus in India. The low-cost automation is on high demand now. Though India has the 2nd highest population,

but getting skilled manpower to run the sophisticated machine is always a big challenge in India. So, we should have SMART machines compatible with multi axis, automation, remote monitoring systems etc. These types of facilities will help the customer to use machines more efficiently. This is the need of the day and we all realised it especially after Covid pandemic. Such innovations are required nowadays to optimize the production and it is available with many machine tools companies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.