Lead time reduction is the primary concern for die and mold industry

By OEM Update Editorial June 16, 2022 5:13 pm IST

This entails a certain degree of standardization and this is where we as a company innovate. We offer a complete range of Standard Parts which will shorten the lead time, says

Vivek Nanivadekar, Executive Director, FIBRO India Precision Products Pvt. Ltd. in an interview with OEM Update

Cost pressures, and competition are some of the chief hurdles in the dies and mold industry as a company, how do you deal with this?

That’s true but it is well-known that quality does command a price. The market, no doubt, is segmented on the basis of cost as well and everybody has a fair share. Quality products however stand apart in the long run. We as a company deal with customers who are looking for quality products. In that segment there is hardly any competition to begin with. Secondly, owing to Covid-19 and the ongoing Russia – Ukraine war, the prices of raw materials have shot up, prompting all the OEM manufacturers to increase prices of their product offerings. So in the given scenario, if the product is available at a cheaper price then it is necessary to check the quality of the product. We as a company take pride in the quality of our offerings and till date there is not a single customer who has had a complaint about the quality of our products.

What according to you are the worldwide trends in the dies and the mold space?

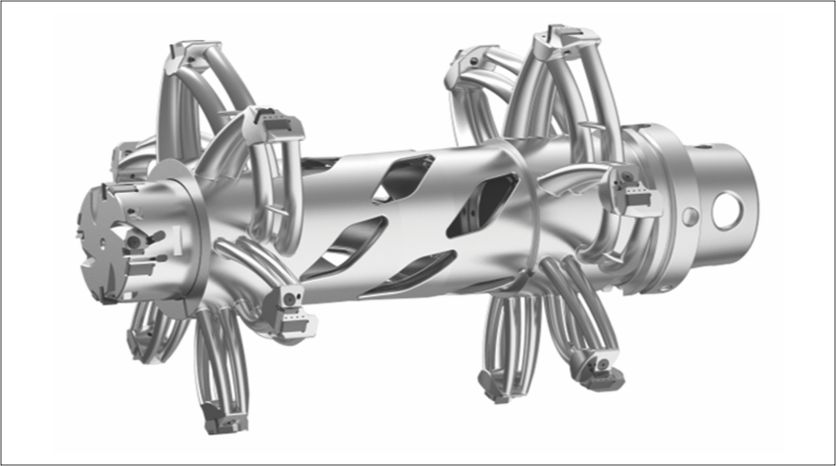

Well, see dies and molds are basically a fundamental part of the manufacturing industry. So, it will remain and continue to evolve. Newer technologies and innovations will come into play. Right now one of the major challenges is how to shorten the lead time. This entails a certain degree of standardization and this is where FIBRO contributes. We offer a complete range of Standard Parts for Dies & Moulds which will shorten the lead time. This ensures the tool maker doesn’t have to invest his time in making such parts, this in turn allows him to concentrate on his core capability such as machining of the cavity. Innovations ultimately have a major impact on the industry. In the automobile industry for example look how it has reduced the ‘Time to Market’ cycle time. Earlier a new car would take years to deliver but thanks to the short lead time of the dies and molds which helps to reduce the cycle time. Now the ‘Concept to Launch of new model’ (TTM) has come down to 12 months. When it comes to our global competitiveness, we are in a good position. Products designed in Europe are pricey likewise in China too labour costs are shooting up and they will lose the price advantage soon. In the backdrop of these developments Prime Minister Modi has expressed his desire to turn India into a global manufacturing hub and, I truly believe we can achieve this goal.

We have the capacity and capability to meet the global demand. What we need to have is a little more training, education and a good knowledge of standardization. If we combine this then we will certainly become a global manufacturing hub. India’s goods exports already crossed a record high $400 billion mark in 2021- ’22, nine days ahead of schedule. So that is an indication that we are heading in the right direction

Most of the manufacturing companies are embracing smart technologies. What does it mean for the dies and molds industry?

Smart technology will also help in reducing the lead time. The smart ecosystem includes smart factory and Industry 4.0 as well, the smart factory in particular enables remote upgrades which is a much needed and desired development. At FIBRO we have taken steps to inculcate Industry 4.0, as a first step we have started collecting data from our machines digitally. In the future it will allow us to implement measures to reduce idle time and improve productivity. Not to mention this will have a direct impact on the efficiency of the entire production process and the total lead time required to produce the end product.

What are the possible improvements the Indian dies and mold industry needs to incorporate to match up to the global counterparts?

As per the survey conducted by TAGMA the Die & Mold sector in India is expected to grow by 10-15 % in the next few years. In fact a couple of Tools Rooms with FDI have already established their set up. This will give us the opportunity to learn and know more about newer technologies and techniques. Existing toolmakers need to absorb the new technologies and utilize them, this will enable us to match up to global standards. Secondly we also need to take a quick look at the curriculum of the technical institutes in India. It needs to be upgraded and the newer innovations and techniques need to be a part of the syllabus. Thereby the toolmakers who graduate from these respective institutes will be aware of the latest developments of the industry. This will make them readily employable in factories where technologically superior techniques and machines are being utilized. So the right kind of training and education is required as well. You can always buy the most innovative machine or equipment but the right kind of training and education will ensure skilled people are available to utilize them.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.