Industry 4.0 concept intensify networking and connectivity

By OEM Update Editorial June 14, 2022 12:15 pm IST

With the increased adoption of digitalization, we have witnessed the emergence of smart factories.

Gary Bateman, Managing Director, LAPP India, while speaking with OEM Update remarked, with the increased adoption of digitalization, we have witnessed the emergence of smart factories.

Innovative trends transforming automation industry

The rise of the automation industry has transformed the way industries work globally. Data communication cables form the backbone of industrial automation. Adoption of Industry 4.0 concepts have led to intensified networking and connectivity. This has highly impacted the automation industry and related connection technology, demanding connections to be more robust, standardised and compact. Today, we see the same production lines being utilised for multiple products, which requires connections to be modular, flexible and robust to function reliably.

With the advent of wireless technology and smart factories, there is a requirement for increasing number of connections to be made in the same installation space, which has given rise to two new trends: miniaturisation and energy optimization.

Product portfolio for industrial automation

The LAPP’s comprehensive product portfolio for industrial automation is built on the 3R principles of “Reliability, Robustness and Ruggedness”, with all[1]round capabilities optimized for harsh industrial environments. The products and solutions are tailored to meet the demands of robustness, flexibility and agility to handle mission-critical tasks on the factory floor demanded by Industry 4.0. Our comprehensive solutions help customers capture the benefits of industrial-grade products.

Our ranges of products include:

UNITRONIC® Data communication systems- High quality data network cables and fieldbus components for all applications in industrial machinery and plant engineering from transmission of simple control signals to field bus signals in complex network structures.

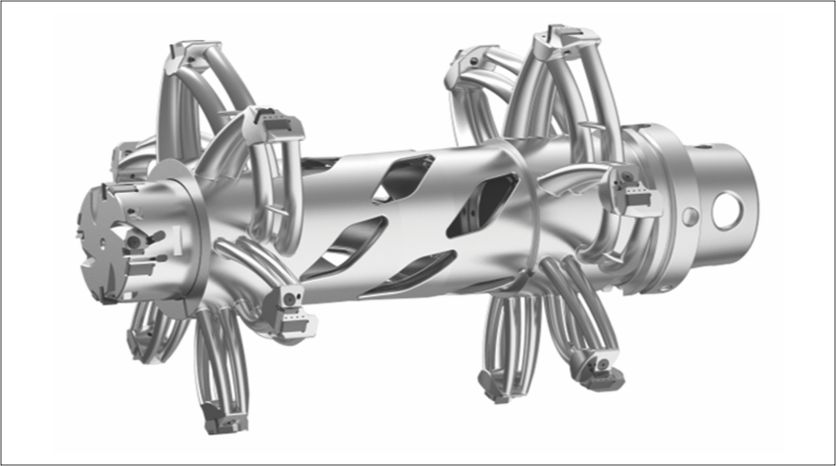

This includes two ranges:Rectangular Connectors- a system of housings, inserts and contacts that offers robust, secure, and easy to assemble solutions Circular connectors- Power and signal circular connectors designed to be used on servo motors and in servo harnessing.

Emergence of smart factories for automated cable manufacturing

With the increased adoption of digitalization, we have witnessed the emergence of smart factories, where millions of devices and components in machines and production lines interact with each other through advanced deep learning and Artificial Intelligence (AI), enabling complex tasks to be remotely controlled and fully automated. Smart Factories are targeted at quicker delivery of individual products to customers. These developments emphasise the focus on data transmission, acquisition, accuracy and analysis as critical building blocks of the new industrial infrastructure. With the increase in wireless technology, there will be an increase in the amount of data that is produced and transmitted. To address this, the cable manufacturers are continuously working towards innovating and improving cables that enable high volume loss-less data transmission.

Industry segments that command major market share for LAPP cables

Industries such as textile, F&B, auto ancillary/ automotive, machine tools as well as oil & gas are the key revenue generating areas for our network cables. With the growing popularity of 5G and wireless technology, we expect to see a spike in demand for cables that can reliably guarantee the high data transmission rates required in automation application across sectors.

Demands from the cable industry applications of industrial automation

As systems and machines continue to become more customised, flexible, and complex under the influence of Industry 4.0, cables must adapt to these changing requirements. The Industry 4.0 revolution demands cables that are torsion resistant, flexible, smaller in size, chemical resistant and light weight. They also need to have additional copper/ aluminium screening to tackle the challenge of electromagnetic interference (EMI). With remote and hybrid working being increasingly adopted by companies, most of the business functions are being executed using automation technology. Cables used in industrial automation also need to be easy to assemble and long-lasting with negligible failure rate and maintenance. Last but not the least, this era of digitalisation is accompanied by a staggering growth in data. This has led to the ever-existing demand for connections to guarantee high data transmission, even in harsh industrial environments.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.