Why CAD/CAM automation software

By OEM Update Editorial August 14, 2017 2:04 pm IST

Featuring the real benefits of CAD/CAM automation software.

CAD/CAM (computer-aided design and computer-aided manufacturing) refers to computer software that plays a crucial role in both design and manufacture products. Nowadays, CAD is the use of computer technology for design and design documentation. CAD/CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining. In other words, CAD/CAM automation software has emerged as a ‘game changer’ in the manufacturing industry which in further helps companies to maximise their programming efficiency by offering greater accuracy and reducing errors. Here’s a glimpse from the industry experts on the real benefits of CAD/CAM automation software.

Most widely adopted technology

Talking about the real benefits of CAD automation software, Varun Gadhok, Head – Manufacturing solutions, Autodesk, India & SAARC says, “Computer Aided Design (CAD) is widely adopted technology by the manufacturing sector with extensive use in verticals such as automotive, shipbuilding, and aerospace, industrial design, healthcare and many more. CAD enables faster design and style changes, thus, allowing versatility and flexibility for experimenting. For example, CAD software can be used to imitate the flow of air around an engine. Quick prototyping further allows developers to create actual prototypes during the designing stage, allowing the designer to instantly see if the style is within requirements at a young stage in the style procedure. Autodesk’s tools and solutions help engineers and designers to experience their 3D CAD designs virtually, before they are built.”

Through design technology, Autodesk is enabling and empowering the future of making things. Being one of the pioneers in design, it is helping to create, manage, and share design data across the entire manufacturing process, bringing better-quality products to market faster, and delivering a complete solution. One of Autodesk’s solutions includes generative design tools which enables the generation of high-performing design alternative- most of which are impossible to make with traditional manufacturing methods. With its help, designers or engineers can input design goals into generative design software, along with parameters such as materials, manufacturing methods, and cost constraints; and by using cloud computing, the software explores all the possible permutations of a solution, quickly generating automated design alternatives.

Gadhok outlines some of the important platforms for the product development:

• Project Dreamcatcher: Project Dreamcatcher is a research platform for generative design.

• Dynamo: Dynamo enables designers to create visual logic to explore parametric conceptual designs and automate tasks.

• Project Fractal: Project Fractal helps users explore design alternatives generated through scalable cloud computation.

• Fusion 360: Fusion 360 is a cloud-based 3D CAD, CAM, and CAE platform for product development. It combines industrial and mechanical design, simulation, collaboration, and machining in a single package.

Way to fix the right solutions

The delivery mechanism in any production vertical has a very sensitive inter-dependency among the sourcing company, vendor network and other internal resource engagements of both sides. In this tough chain, the key challenge lies on the floor level operators who would face ultimate pressure as they get engaged in the entire delivery cycle. In fact, the expensive machines and automation mechanisms involved in these segments demand critical operational mandates and greatest degree of co-ordination from these ground level operators as the design and other programmed inputs to such machines to be so much precious and highly accurate. At the same time, the turnaround time (TAT) to the supplier networks to deliver products has been critically reduced to map the competitive cost.

Eventually, K. Manickam, Managing Director of CAD Macro Design and Solutions Pvt Ltd observes CAD / CAM solutions are the only way to fix the right solutions to win highest precision, ultimate accuracy, reduced cycle time, improved monitoring mechanisms and to optimise the production cost as they are being the interfacing platforms between the human resources and the high precision machines. By and large, the said parameters only could lead and contribute a Total Quality Management (TQM) system in any competitive production environment.

He adds, “The global competition not only demands the best quality but also had established lot of sensitive mandates to ensure perfection in every inch starting from design up to the final dispatch in the production sectors. By taking this into account, we have been consistent in our 15 years of passionate journey by keep adding software solutions in CAD / CAM in terms of wire EDM, lathe, CNC, tool room ERP and relevant process simulators to support the floor level mandates of mechanical engineering.”

CAD/CAM automation software is a ‘game changer’

Speaking about the real benefits of CAD/CAM automation software, PM Ravikumar, Sr. Director, Professional Channel (SOLIDWORKS), Dassault Systèmes India says “CAD/CAM automation software is a ‘game changer’ in the manufacturing industry. It aids companies to maximise their programming efficiency by offering greater accuracy and reducing errors. This not only helps in reducing the time that would have been consumed in creating prototypes manually but improves the design of the product drastically.”

Ravikumar adds, “Many manufacturing companies are investing in advanced manufacturing technology including FMS, various CAM systems, etc. The availability of a well-constructed and validated computer model allows the systems designers, the engineers and the managers to understand in advance the detailed consequences of their decisions and the investments prior to actually making binding commitments. Part designers and product engineers can improve their product performance and quality while reducing uncertainty and cost by using simulation to help guide design decisions.”

One of the things that differentiate SOLIDWORKS from other CAD systems is its extensive CAD ecosystem of solutions that provides users with the tools they need to optimise all areas of product development, not just design. SOLIDWORKS solutions focus on providing engineers and designers with the tools they need to innovate better and faster. By implementing CAD automation, engineer-to-order manufacturers can complete days of custom engineering in just minutes. Ravikumar informs, “Engineers can overcome the difficulties encountered in customising a product by using design automation tools available in SOLIDWORKS. It also helps in the completion of repetitive engineering tasks enforcing engineering decisions that prevent sales from specifying noncompliant or non-manufacturable products.”

CAD/CAM/CAI results in reducing the time-to-market

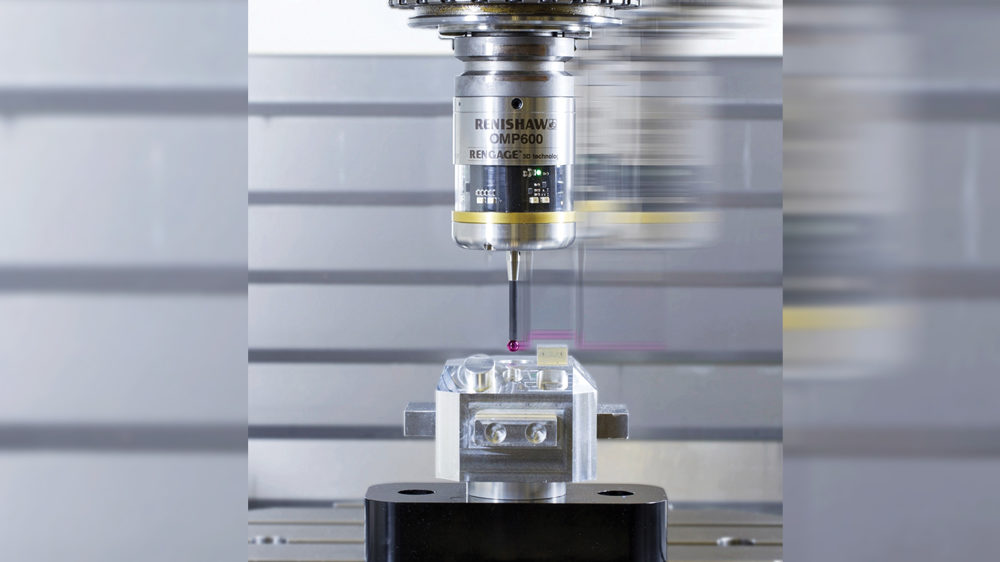

Sharing his opinion on the real benefits of CAD/CAM automation software, Vineet Seth, Managing Director – South Asia and Middle East, Mastercam says, “It is evident that the world is moving towards automation. Technological advancements – particularly in CAD/CAM/CAI have reduced the time-to-market drastically.”

He informs, “Using Computer Integrated Manufacturing, we are now able to virtually monitor and control everything in the machine shop and production centre, without having to be present there physically.”

According to Seth, CAD/CAM automation software offers many benefits by way of automating manual tasks that are otherwise prone to delays and errors. Some of the benefits are as follows:

• Wizards / Process oriented workflow

Most CAD and CAM tasks today are driven by wizards. These wizards are typically process oriented and follow a structured way of achieving the desired results. These wizards also incorporate best practices that ensure that even novice users are able to quickly learn and apply these processes on complex parts within a very short period of time.

• Toolpath Strategies

In relation to CAM, toolpath strategies allow for CNC programming of the most complex of parts, using a graphic representation of the kind of toolpaths that will be generated upon applying a specific strategy. This allows the programmer to have a visual approach to toolpath generation. Further, through form based controls, strategies encompass various parameters that can be tweaked by advanced users.

• Knowledge Based Machining

• SimulationSimulation is an essential part of both CAD as well as CAM. Not to be confused with CAE, simulation in the CAD sense means to virtually and visually show kinematics, movements and motions of parts and assemblies; in the CAM sense, it means to virtually and visually show kinematics, tools, parts, movements, paths, and collisions in a given machine tool environment. Simulation allows for corrections in complex toolpaths to avoid collisions, unwanted air moves, axis transformations and undesirable motions, amongst others, before the part is actually cut on the CNC machine. This saves time and costly accidents on the CNC machine.

“Lastly, online process monitoring systems ensure that the production process is being ‘controlled’ by a well-defined system, it allows more time for operators, supervisors and managers to focus on ‘maintaining’ the system by means of continual study of live as well as historical assessment reports, error identification, RCA and capacity management,” adds Seth.

Design or CAD Software’s helps with speed and quality

Sharing his opinion on the real benefits of CAD/CAM automation software Raju Battula, National Manager- Technical Support, DesignTech Systems Ltd, says “Design or CAD Software’s in general help the designers to do the required task with speed and quality. But if the same designer needs to design variants, perform repetitive tasks, accelerating the process of design and also save time we need to look to design automation.”

Battula opines, “CAD/CAM Automation is presently considered by many established and upcoming companies. This is to preserve the critical knowledge and design intent. Automation is used to save time and make the designs faster; this is because of the pressure from either end customers or from manufacturing division.”

Explaining the role of process automation, Battula states, process automation involves understanding the repetitive tasks and start reusing them so that there is no need to design the same. It also includes, writing design rules to minimise error and save the time from manual errors. Further, it helps designers to think different as the basic design is ready and need to enhance the cycle of design.

As per Battula, most of the design automation can be worked in following methods are as follows:

• Bottom Up

• Here designs are done from small parts to complex components/assemblies

• If a design needs to be done in multiple variants then we can make logics which create the designs with less effort.

• Drawings can be done after executing the designs.

• Master Model

• Here Automation will have an UI and enter the requirement.

• With this requirement one can get the parts, assemblies, drawings and even any info required like process sheets, manufacturing plans etc.

• Defining hot keys

• Defining macros

• Write the validation program to make the design feasible for delivery to next coming up operations.

Further, Battula explains the main advantages of automation i.e. setting up design process, minimising design cycles time, effective design process, adding up GD&T in automation will minimise manufacturing problems, validation of designs can be done faster and last but not the least automation can also be done in preferred automation language.

Users of CAD software

Manoj Pagariya, Managing Director, Richcam Auto Engineering (I) Pvt. Ltd concludes “We are user of CAD-CAM software from 2004 and we are using both CAD software as well as CAM software.”

Further, Pagariya points, CAD software is used for 3d designing, modeling, drafting, assembly.

• We can design complex shape.

• We can visualise actual shape of part in 3d view.

• We can check part clashes in assembled condition.

• We can further simulate this part for crash test, stress-strain analysis, transfer simulation, light effect.

• We can use same model for machining purpose.

• If we modify part any level, its related assembly, CNC program will be modified automatically.

• It is beneficial to check wt of end product and can be used for costing purpose.

• We can make cost effective design, error free design. Even, we can check failure analysis.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.