Renishaw to highlight metrology products at Die & Mould 2016

By admin April 13, 2016 5:50 pm IST

At the Die & Mould 2016 exhibition taking place at Bangalore International Exhibition Centre, Bengaluru, from 6-9 April, Renishaw will highlight a range of process control solutions that help tackle the increasing drive to lean manufacturing, from new technologies for pre-process machine calibration, to on-line and off-line post-process measurement. There will also be a significant focus on the company’s additive manufacturing (3D printing) systems with the new PlusPac upgrade for its AM250 additive manufacturing machine.

The company will have active demonstrations of its Equator gauging system along with various machine tool software catering to die-mould industry.

Renishaw is the UK’s only manufacturer of a machine that ‘prints’ metal parts and visitors to the Renishaw stand will be able to see applications that demonstrate the capabilities of the company’s additive manufacturing technology and Strain gauge high-accuracy machine tool touch probes – Unparalleled accuracy and repeatability make this technology the best choice for complex multi-axis work and machine calibration.

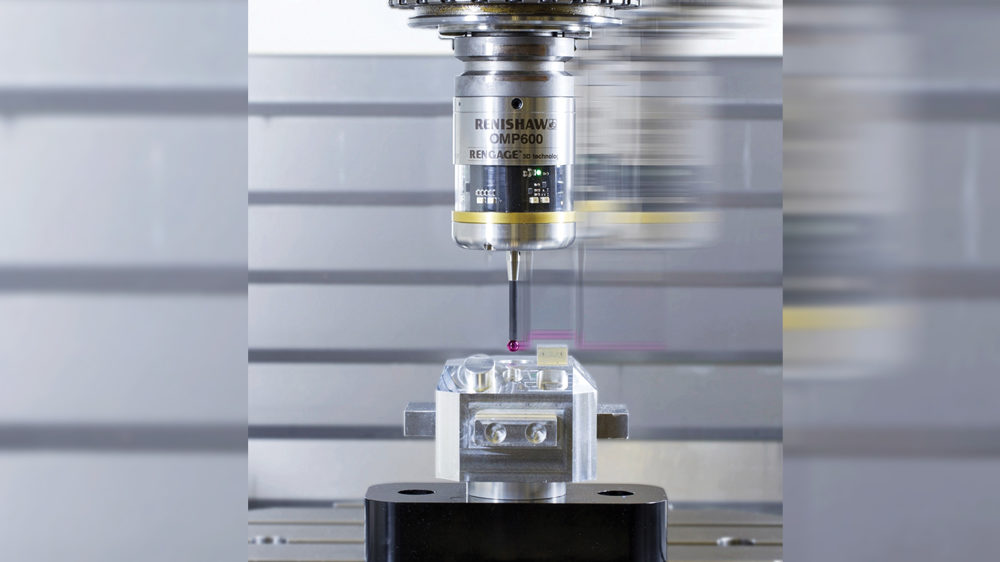

RENGAGE technologyRENGAGE technology delivers true three dimensional (3D) measurement performance and submicron repeatability. So for exceptional performance, reliability and durability, why choose anything less? Conventional probes continue to fulfil a valuable role, which is why Renishaw maintains its position as market leader in the design, manufacture and support of these products.

However, for numerous applications, the significant performance benefits offered by RENGAGE technology provide users with a competitive advantage, for both now and the future. RENGAGE technology is available with radio transmission in the RMP600; with optical transmission in the ultra-compact OMP400 and compact OMP600; and in the miniature MP250, offering an unmatched combination of size and accuracy.

The Primo system – opening up the world of precision manufacturingAt Diemould Renishaw will be highlighting the Primo system: an entry-level machine tool probing system that opens up the world of precision manufacturing to all types of manufacturing operation. A genuine breakthrough business model, the Primo system makes it easy for manufacturers to take their first steps towards higher-value manufacturing by automating their operations and achieving repeatable processes.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.