Optimum workpiece costs for every batch size

By admin May 12, 2016 3:48 pm IST

DMG MORI demonstrates i 50, a revolutionary horizontal machining centre, at SIMTOS

In the past few years DMG MORI Systems has developed to become a holistically-oriented supplier of sophisticated automation solutions. Its offer ranges from solution development to simulation and on to implementation of solutions for the customer. In addition to the machine integrated automations of the supply plants with their rotary or pallet storage systems, the portfolio also includes standard automation solutions for workpieces and pallet handling as well as turnkey projects with manufacturing cells and production lines. At SIMTOS visitors will see i 50 being an important part of highly productive automation solutions.

“The customer’s production and assembly process is decisive for automated solutions,” explains Silvio Krüger, Managing Director of DMG MORI Systems. “The challenge for our engineers and technicians is to understand the production system requirements and to provide the customer with an efficient production solution.” This is where DMG MORI Systems as a turnkey supplier comes in. Silvio Krüger names the required workpiece output, the technical availability of the entire system, a machining system that can be used variably and of course quality as influencing factors.

DMG MORI Systems benefits from DMG MORI’s many years of experience in automation solutions and its entire system competence in the achievement of these goals. With Wernau, Hüfingen in Germany and Nara in Japan DMG MORI Systems now has three lead locations within the International Group, in which the focus is on joint product development and project management.

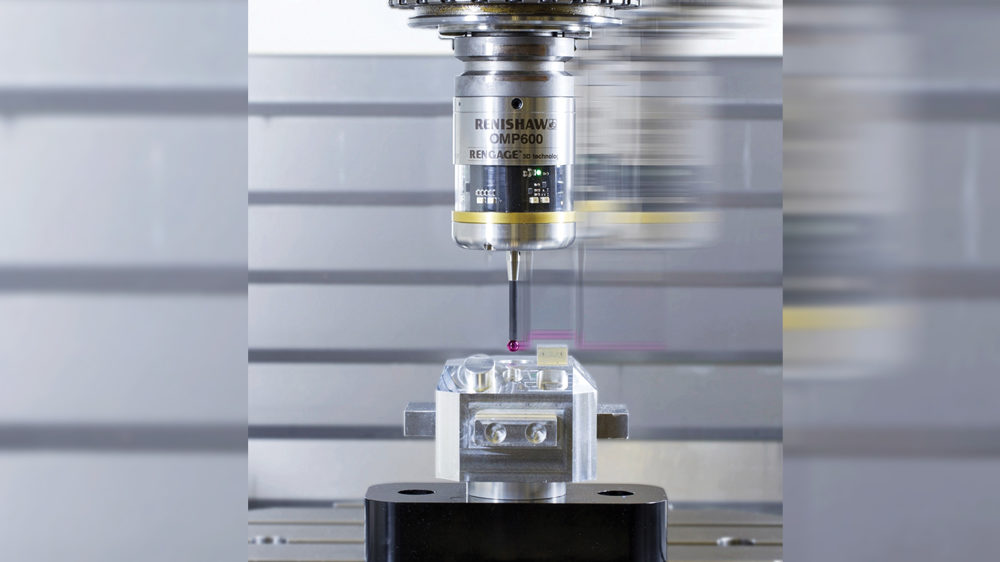

i 50 in stealth design – high-productivity horizontal machining centreIn addition to the demand for highest productivity and precision as well as maximum reliability in multi-shift continuous operations, the space requirement is one of the most important factors in the decision-making process in the automotive industry. As a result, DMG MORI has developed i 50, a horizontal machining centre with a revolutionary design concept for space-saving serial production tasks.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.