Manufacturing Transformation with Connected Shopfloor

By OEM Update Editorial June 29, 2017 5:22 pm IST

Digitisation is actually a game changer for Indian manufacturing owing to the immense possibilities it has in store.

OMRON Corporation, a global developer of industrial automation products, offers a range of solutions for smart factory. Though digitisation is a far cry for manufacturing companies in India, Sameer Gandhi, MD, OMRON Automation India believes, these manufacturers can now actually leapfrog the automation investment phase by adopting digitalisation and other smart factory technologies. Interview excerpts:

Enabling ‘true’ digitisation

Digitisation (IoT) can play a very crucial role in the manufacturing process. It is a futuristic and progressive step ahead to help the businesses get transformed into a ‘completely connected shopfloor’ where data is collected from various sensors and other input devices to be used for not only reducing production cost but for many more purposes which will prove exceptionally beneficial in the long run such as predictive maintenance, better control and long-term analysis. Any smart device or sensor in the field today has a lot of data related to the device or sensor itself. But so far, this data is not really accessible beyond this device. True digitisation enables this data to be captured and made available in real time for analysis to improve the maintenance, productivity and competitiveness.

Digitisation is a far cry for many

Digitisation is actually a game changer for Indian manufacturing owing to the immense possibilities it has in store. It can enable them to improve their productivity and quality manifold.

Many of the Indian manufacturing companies have not yet invested extensively in the traditional automation, so digitisation is a far cry for them. However, these manufacturers can now actually leapfrog the automation investment phase by adopting digitalisation and other smart factory technologies.

Some sectors such as automotive, food and beverages, and pharmaceuticals are surely showing positive signs where many progressive manufacturing giants are adopting the technologies effectively. However, the whole paradigm will need some more time to expand and evolve.

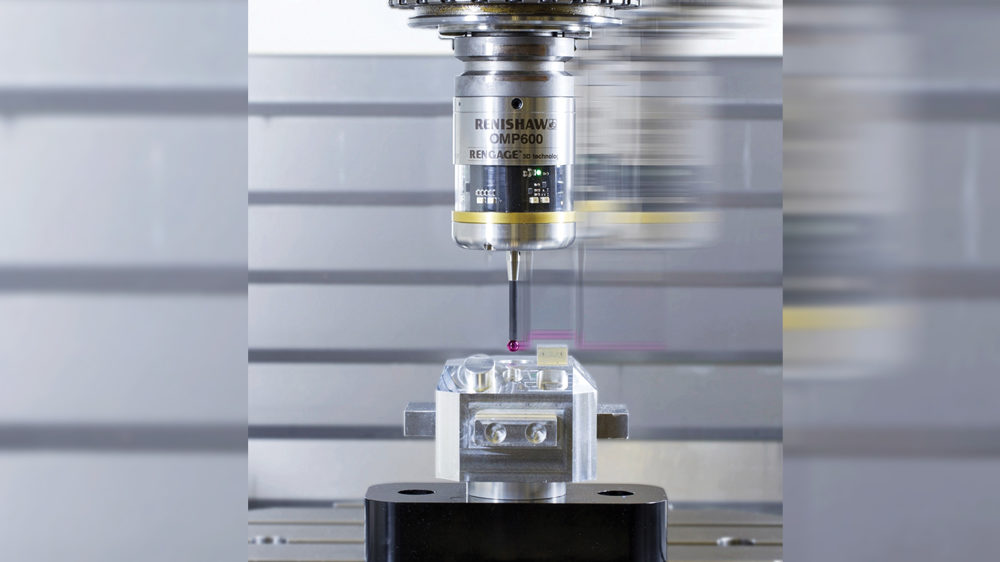

OMRON’s complete solutions for smart factory shopfloorMany of OMRON’s products are designed for smart factories. The automation giant’s product basket includes IoT enabled sensors, IO links to gather data, PLCs that can communicate directly to the ERP/MES layer and robots that can work together with humans and smart vision systems for QI. But more than just offering discrete products, OMRON can provide complete solutions for the smart factory shopfloor.

For example, the sensor health data gathered from multiple smart sensors through the IO link, can be analysed in OMRON’s PLC to predict failures and trigger maintenance alerts to order spares to the MES (manufacturing execution system) or the PLCs monitoring a production line can command the Lynx mobile robot to feed the raw material to the required sections of the plant.

OMRON to acquire industrial camera maker Sentech

OMRON Corporation has recently announced that it has entered into an agreement with Sentech, a manufacturer of industrial cameras to acquire ST and make ST and its subsidiaries members of the OMRON Group.

OMRON offers a wide variety of products, ranging from input devices such as vision sensors to output devices such as controllers and servo motors, as well as safety devices and various industrial robots. By combining these devices, OMRON has supplied manufacturing sites throughout the world with sophisticated automation technologies. Through the acquisition of ST, OMRON expects to further evolve its world-leading role in automation.

Through the acquisition of ST, OMRON will work to develop an ultra-compact and high-definition smart camera1 that can be easily installed virtually anywhere. This can be achieved by combining ST’s design technology for creating compact, high-resolution, and high-speed cameras with OMRON’s high-speed and high-accuracy image processing technology. Moreover, OMRON will be able to develop and incorporate an ultra-compact camera into a pick-and-place robot arm to enable 3D recognition of objects.

“The combination of OMRON’s technologies and ST’s one will also enable new automation systems that eliminate the dependence on human vision. This will help free operators from demanding visual inspection tasks, while allowing OMRON to develop new markets,” OMRON claims.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.