Industry 4.0 will change the way industries work

By OEM Update Editorial June 30, 2017 4:07 pm IST

Industry 4.0 is all set to become a reality in India soon, transforming radically the way industries work and do business today.

Marc Jarrault, Managing Director, Lapp India

Digitisation offers endless opportunities

Technology plays a key role in efficient manufacturing. The initial implementation of evolving technologies can lead to a significant competitive lead. As a result, many manufacturers are adapting to digitisation to better the productivity, quality and profitability.

According to Marc Jarrault, Managing Director, Lapp India Pvt Ltd, “Digitisation has now gone beyond being more paperless and is more about smart technology and smart factories. Adapting to digitisation offers endless opportunities which allow improving on efficiency, quality, accuracy, precession, safety and health.”

Heading towards a major facelift

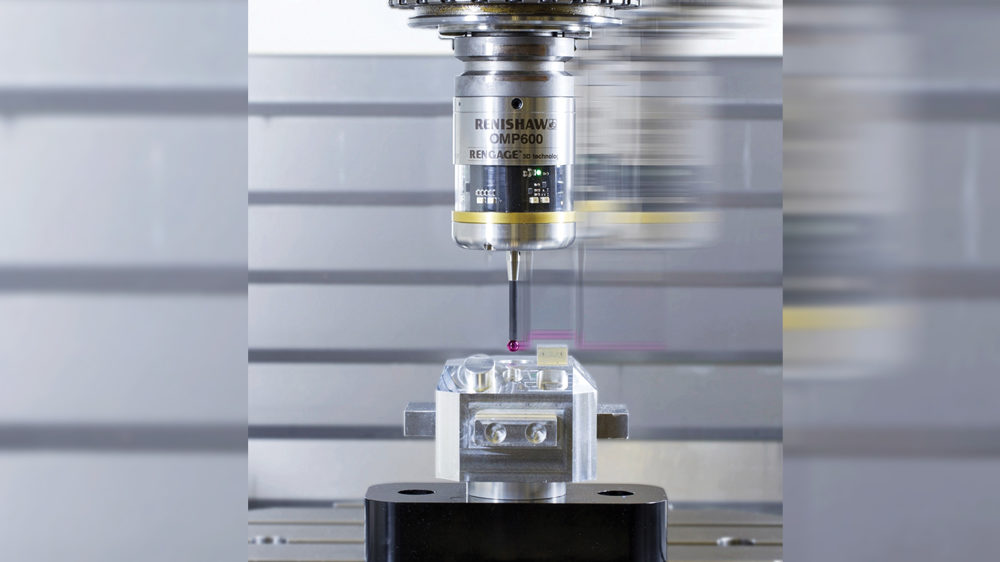

Introduced by Germany, Industry 4.0 or the fourth industrial revolution concepts are in harmony with worldwide initiatives, including Smart Factories, Industrial Internet of Things (IoT), Smart Manufacturing, and Advanced Manufacturing. This revolution in manufacturing landscape is changing continuously across boundaries for greater efficiency.

We are on the edge of Industry 4.0 where technologies such as big data, improved data analytics, machine-to-machine communication, advanced robotics and 3-D printing are transforming the fundamentals of manufacturing. The Indian manufacturing sector looks to be heading towards a major facelift now, observes Marc. He adds, “Industry 4.0 is all set to become a reality in India soon, transforming radically the way industries work and do business today.”

Experts believe that India’s thrust towards ‘Make in India’ should keep in cognizance Industry 4.0 and begin its positioning in this space. “We have seen that each industrial revolution has happened faster than last, so if India acts soon it can surpass other countries’ work to become one of the manufacturing leaders of machine tool in the world,” Marc puts forward.

Lapp products for ‘smart factory’

Lapp India has a vast range of products for the smart factories are:ÖLFLEX power and control cables are the first multi core cable to be manufactured in the world. These cables are suitable for 3-axis rotation applications and also for applications with very high linear bending stress. The cables are designed to be low loss, slim in construction, light in weight and have high flexibility. The brand is known to be robust and is heat or temperature resistant

UNITRONIC, data transmission devices – is highly effective in avoiding leakage of signals during Data Transmission. This is achieved by using tinned copper braiding as a screening material against EMI interference. This is the brand of choice if you want fast, safe and forward-thinking solutions for transferring data. The range includes data cables for all electronic applications, from tiny cables in coffee machines to those transferring huge amounts of data in supercomputers.

ETHERLINE Ethernet technology-based networks are playing an increasingly important role. Lapp therefore offers reliable system solutions for network technology. The range includes products, software solutions and services for total security and availability.

HITRONIC fibre optic cables are designed to transfer large volumes of data. Communications media via fibre optics are fast, efficient, and secure. Not even electromagnetic interference can affect HITRONIC fibre optic cable. The HITRONIC range of products includes cables for office communications, industrial applications, simplex, duplex, hybrid wiring, or cable chain applications.

Lapp has also introduced ÖLFLEX CONNECT, a customised plug ‘n’ play cable assembly. With the years of experience and backed by the team of industrial experts, LAPP is able to offer a huge array of cables and connectors that are unique for the machine tool industry like OFLEXROBOT 900 P, OLFLEX ROBOT F1 and ÖLFLEX CHAIN 808. “Whether you need custom cable assemblies, servo cable assemblies for moving application or a populated cable chain, ÖLFLEX CONNECT is your one-stop source for all cable assembly solutions systems requirements,” asserts Marc.

Bridging the paper and digital gap

When it comes to operational front, Lapp has an ERP – SAP system in place where in the work order flows through the system and is mapped periodically. However, now the company is in the process of upgrading its SAP system further wherein the entire process is managed digitally. There will be no paper work necessary, informs Marc. He adds, “In each step of the process there will be bar coding which will improve traceability. Order confirmation will also be done digitally. This will have more yields and shall optimise the entire process.”

Upon digitisation, the warehouse will witness all the invoices and documents being generated in the system. This will eliminate the need to print hard copies of documents. Uploading and sharing of documents will be done electronically. The customer service becomes much faster and better.

“We are also eager to embrace Industrial Internet of Things (IIoT) and Industry 4.0 coming in our way and experience its impact. We believe the transformation in future would be of automation through digitisation,” concludes Marc.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.