Adopt Industry 4.0 to gain competitive edge

By OEM Update Editorial June 30, 2017 4:16 pm IST

Industry 4.0 – the new paradigm of IT enabled intelligent manufacturing has already arrived and we need to adopt it quickly to be competitive.

Guruprasad Kuppurao, CTO and Founding Member, Imaginarium India

Imaginarium claims to be one of the earliest adopters of digitisation and has been producing jewellery with the help of 3D printing for over 14 years – going from digital design to end product qualifies as rapid manufacturing. The company’s Chief Technology Officer and Founding Member Guruprasad Kuppurao talks about the importance of adopting digitisation in manufacturing process.

Why digitisation in manufacturing process

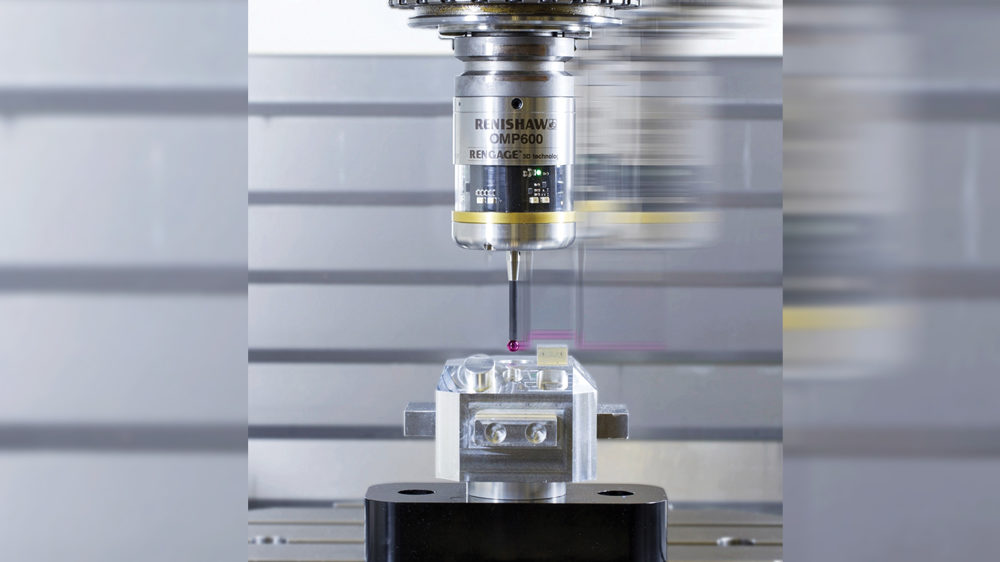

Digitisation in manufacturing goes a long way back. Every attempt to automate has been a step towards digitisation. A perfect example is the “Jacquard” templates, used for textiles. The advent of computers saw man teaching machines to read an automation program. Furthermore, Moore’s law gave a big impetus to digitisation and made it affordable. The way we manufacture things has dramatically changed since industries have attained digital maturity. Hand drafted drawing made way for computer aided drafting and with innovations in designing technology, it eventually took the form of virtual designing, now known as Computer Aided Designing (CAD). These designs are referred to as solid models. With the right attributes, they are capable of providing precise information about the end product – its volume, weight, photorealistic rendering and even 2D drawing. This led to an upgrade in design flexibility and reusability. Called “Parametric Design” it further automated the design process. NC became CNC, but it still had a lot of limitations. The scenario changed forever and changed for good with the invention of 3D printing. While it appeared in it first Avatar as Stereolithography (SLA Process), it soon proliferated into many such processes such as Selective Laser Sintering (SLS), Laminated Object Printing (LOM) and Fused Deposition Modelling (FDM). They brought in with them the freedom to design without any constraints and make things which were initially deemed as impossible to make! The input is a digital model and end result is a physical model. This offers best control over manual manufacturing and fabricates things on demand. The world which was looking for agile options to manufacture products finally had its solution. Computers, digital models and converting technologies will redefine the way things will be made in future. It is important as it offers flexibility, control and variety.

Digital manufacturing is yet to mature

While India is quite advanced in IT sector, the digital manufacturing industry here is yet to mature when you look at other, more advanced markets around the globe. Indian automakers were the first to adopt this technology. But given the price sensitive nature of the market, digital manufacturing has not been fully exploited and is primarily used for prototyping purposes. Only a handful of sectors like jewellery and dental are utilising this technology for their business processes. If we compare it with the rest of the world, we still have miles to go. Today, major industries have become digitally mature: all their designs are done as digital solid models. But there is a need to transcend to digital fabrication. Here, 3D content creation skill is a gap and needs to be bridged first. Sectors like aerospace and medical will derive the best support from digitisation. We find pockets of industries moving ahead with respect to adopting 3D printing and they show the potential to make it contagious, for this what is needed to keep processes agile. Industry 4.0 – the new paradigm of IT enabled intelligent manufacturing has already arrived and they need to adopt it quickly to be competitive. Organisations like FICCI, DOH and CII along with the Govt of India have been reaching out to industries to spread the awareness and help accelerate adoption.

What is a smart factory?

A ‘smart factory’ is an agile manufacturing setup with a dynamic flexibility to produce anything and in any number, even for a required quantity of a single piece! The process is then known as fabrication as opposed manufacturing in bulk. Since digital inputs drive it, it is termed as digital fabrication.

• Agility

• Customisation or individualisation of products

• Make one or many but never a million!

• Most complex geometries (organic forms).

• No problem with undercuts.

• Preassembled systems and subsystems.

• Produce on demand.

• Power efficient, eco-friendly optimised workflow

• Self-correcting systems.

• Smaller physical footprint.

Embracing digitisation since 2000

Imaginarium is one of the earliest adopters of digitisation and has been producing jewellery with the help of 3D printing for over 14 years – going from digital design to end product qualifies as rapid manufacturing. The process wasn’t quite simple, it involved learning and adopting a variety of practices such as digital design creation, without which printing would have been nigh impossible. Today Imaginarium is recognised as 3D printing experts, and are applying this amazing technology in every possible industry. The company has invested in state-of-the-art hardware and software for making 3D printing a reality. The most crucial of these investments was the ‘liveware’ – the skilled, trained and motivated manpower.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.