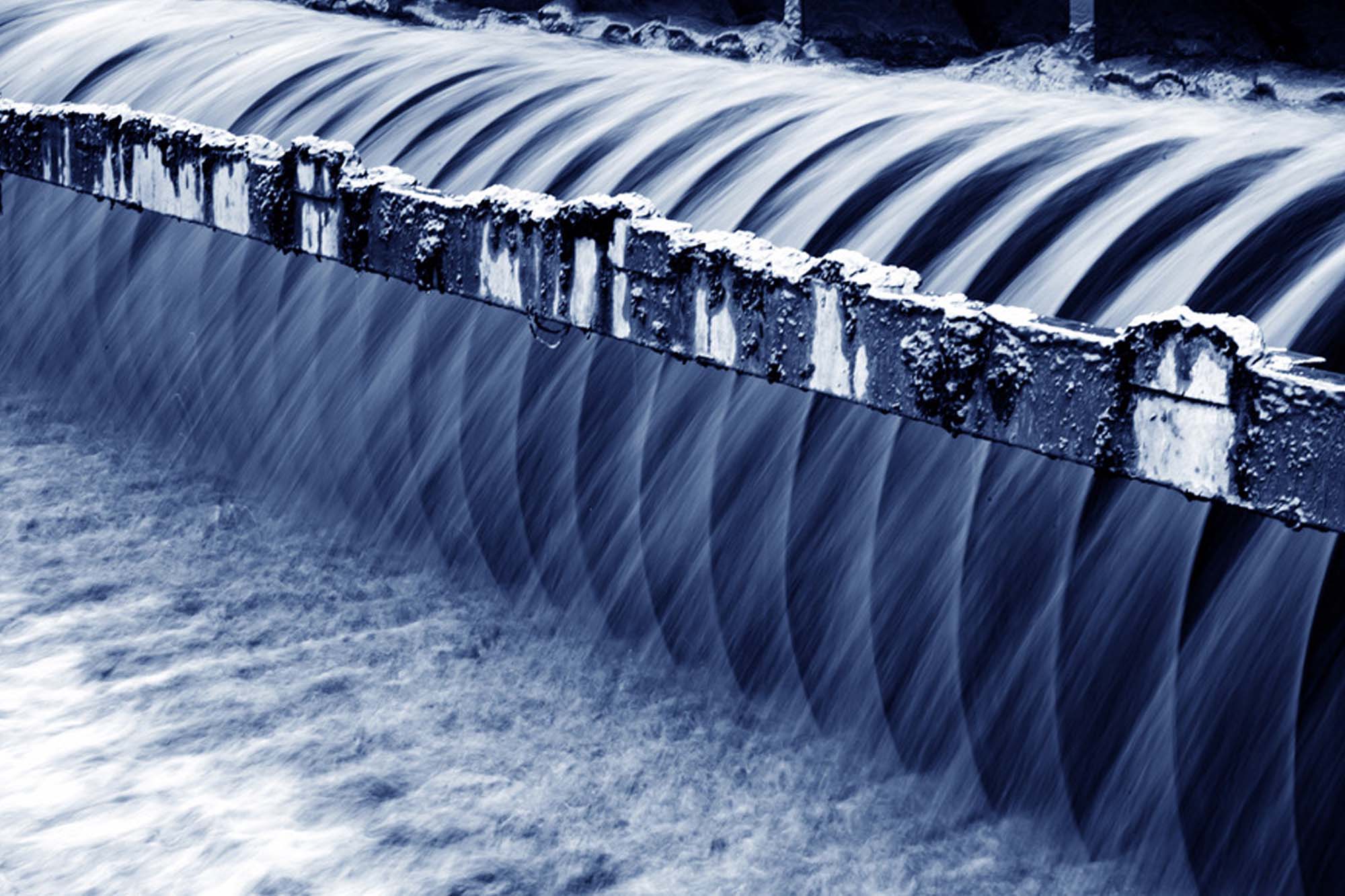

Optimal wastewater management in manufacturing

By OEM Update Editorial April 30, 2024 7:17 pm IST

In the face of water conservation, manufacturing industries are to adopt innovative approaches to wastewater treatment and water recycling. By embracing advanced technologies, they are ensuring operational resilience and resource efficiency. The story explores how technological advancements and sustainable practices are shaping a more efficient future for water treatment.

The substantial release of wastewater into the environment hinges upon industrialisation and a growing population. Efforts to tackle challenges encompass enhancements to wastewater treatment facilities, ongoing water quality monitoring, and the implementation of water recycling for diverse purposes such as irrigation and industrial use. Further, reducing water usage in manufacturing processes can contribute to long-term water sustainability.

Emerging industrial, urban, and agricultural contaminants threaten water sources and ecosystems. Their presence can disrupt aquatic ecosystems, impacting biodiversity and food chains. Contaminants in drinking water sources also pose health risks due to inadequate removal by conventional treatment methods. Dharmendra Pratap Singh, COO of MEP Projects & Engineering Services at Voltas, highlights the concerning toxic impacts of emerging contaminants, particularly from sectors like pesticides, pharmaceuticals, dyes, and pigments., prompting the need for treatment methods involving chemical precipitation and filtration.

Wastewater technology

Recently, there has been a shift within the wastewater treatment sector towards embracing bioremediation technologies. Priyanka Khaire from Organica Biotech explains that bioremediation, a natural and eco-friendly process, employs microorganisms to break down and neutralise pollutants in wastewater, thus lessening their detrimental effects and facilitating water recycling.

Dharmendra emphasises the urgent need to explore new technologies as less than half of India’s wastewater undergoes treatment. Widely accepted technologies like Geographic Information Systems (GIS) and Supervisory Control and Data Acquisition (SCADA) are utilised in the water industry. IoT platforms employ AI algorithms to detect pump or motor failure and chemical consumption.

Chandrashekar Hariharan, Head of AltTech Foundation, stresses the importance of transitioning to Net Zero Water, stating it is necessary given the challenges associated with water sourcing, storage, distribution, and wastewater disposal. The new water policy introduced in early 2023 is a step in this direction, but it requires a combination of incentives and regulations to ensure compliance and training for inspectors.

Rajesh Jha, Country Environment & Sustainability Manager, ABB India, explains the various factors considered when selecting water treatment technologies, including installation and maintenance costs, regulatory requirements, and the intended reuse of treated water and wastewater. Meanwhile, Mandar Vaijnapurkar from Danfoss highlights the substantial energy consumption of water and wastewater treatment processes, with pumping machinery being crucial. Proper maintenance is essential to avoid premature wear and tear, reducing replacement costs.

These methods align with energy production within wastewater treatment plants. Utilising methane facilities like biorefineries demonstrates the potential for energy recovery. Priyanka elaborates that these microorganisms are adept at degrading a wide range of pollutants, resulting in cleaner effluents that can be reintroduced into the environment safely.

Recycle and reuse

Efficient wastewater treatment within manufacturing facilities is crucial for environmental sustainability and complying with regulations. Manufacturers can effectively eliminate contaminants from their wastewater streams by deploying advanced technologies such as biological treatment, membrane filtration, and chemical precipitation. Anil Sethi from Pump Academy advocates the implementation of India’s Zero Liquid Discharge (ZLD) policy, which mandates industries to treat and recycle all their wastewater, resulting in no discharge. This policy requires industries to adopt advanced treatment methods to recover valuable resources like water, salts, and other materials.

Recycling and reusing treated water reduces discharge volumes and minimises environmental impact. Regular monitoring and maintenance of treatment systems are essential to ensure optimal performance and compliance with regulations. Propelling efficient wastewater treatment in manufacturing processes is crucial for mitigating pollution and fostering sustainable operations.

Mandar Vaijnapurkar highlights the emergence of ZLD and Minimal Liquid Discharge (MLD) as highly effective wastewater treatment processes. These processes aim to enhance water reuse and decrease industrial wastewater discharge. Traditional thermal-based ZLD/MLD systems are particularly energy-intensive, but incorporating membrane-based processes can potentially reduce energy consumption by up to 75 percent.

Shardul Apte from Goldfinch Evaporating System emphasises the increasing importance of water conservation within industries, given the scarcity and quality of water resources. There is a growing imperative for industries to optimise water usage, potentially modifying processes to minimise water consumption and thereby indirectly reducing wastewater generation. Generated wastewater is then treated based on tailored processes to optimise operational costs.

The methodology for achieving Net Zero Water status in manufacturing facilities is now more accessible, enabling industries to set goals and objectives accordingly.

Water treatment methods

Advanced treatment technologies such as advanced oxidation, membrane filtration, and bioremediation are crucial in eliminating contaminants from water sources. Equally important is preventing the introduction of pollutants and contaminants at their source through proper waste management and sustainable agricultural practices. Regulatory frameworks are pivotal for monitoring and controlling contaminant discharge. Dharmendra reviews compliance with regulatory standards, proactive maintenance, and continuous monitoring, which are essential for reliable operations. Compliance with regulatory requirements and discharge standards is crucial, aligning with local or national regulations governing effluent discharge limits. Evaluating the chosen technology’s removal efficiency, reliability, robustness, and operational requirements, particularly concerning existing treatment infrastructure, is essential.

Furthermore, assessing energy requirements and operational costs, including the consumption of chemicals, additives, or other resources necessary for the treatment process, is paramount. Exploring resource recovery or reuse opportunities within the treatment system while minimising overall carbon emissions within acceptable limits is advisable. Selecting a treatment technology that meets future needs ensures sustainability and flexibility in the long term.

Challenges of water treatment plants

Managing water usage and wastewater treatment in manufacturing facilities poses numerous challenges. In regions with limited water availability, obtaining sufficient water for production and ensuring proper wastewater treatment are difficult. Industries like chip and semiconductor manufacturing require pure water for precise processes, where even slight impurities can cause defects. High water consumption is commonality in manufacturing, particularly for processes requiring ultra-pure water, making it challenging to manage and reduce water usage while maintaining production efficiency.

Consistent water quality is crucial, as water scarcity can halt manufacturing processes. The volume and composition of wastewater can vary, complicating effective treatment, especially for contaminants like heavy metals and organic compounds. Operating wastewater treatment systems incurs operational costs, and balancing these with production costs while remaining competitive is challenging, especially for small facilities lacking resources for advanced treatment technologies.

Shardul highlights that advanced treatment processes can be indispensable where conventional technologies fail, offering reduced footprints and operational ease. Wastewater treatment challenges vary by region due to water availability and industrial activity. The cost of treatment facilities is affected by effluent flow rates, water quality, and construction materials, while energy consumption is significant. Overcoming challenges requires adequate funding, public-private partnerships, and innovative financing models.

Priyanka emphasises that industrial water usage presents unique challenges that require careful consideration and innovative solutions. These challenges arise from various factors, including the diverse range of pollutants in industrial effluents, strict regulatory requirements, and the need to optimise water usage while minimising environmental impact.

A key challenge lies in the variety of contaminants in industrial wastewater, spanning chemicals, heavy metals, and organic compounds. Effectively removing these pollutants requires tailored treatment approaches that can be complex and resource-intensive. Therefore, water treatment plants must invest in advanced monitoring and treatment technologies to consistently meet these standards and ensure water safety for industrial use.

Another significant challenge is optimising plant operations for maximum efficiency. Industries face increasing pressure to minimise water consumption, energy usage, and waste generation, necessitating innovative solutions that treat water effectively while reducing the environmental footprint of the treatment process itself. The challenges of ensuring water quality and safety for industrial use are multifaceted, encompassing diverse pollutant profiles, regulatory compliance, and resource optimisation.

Sewage-to-water recycling

In an era of water scarcity and competition for freshwater resources, sewage water recycling emerges as a sustainable solution. This approach alleviates pressure on limited water sources, promoting environmental responsibility and cost-effectiveness. Dharmendra notes that sewage water recycling reduces reliance on purchasing and transporting freshwater, improves resource efficiency, and aligns with corporate social responsibility goals.Moreover, sewage water recycling establishes a reliable water supply unaffected by external factors like seasonal variations or droughts, ensuring process stability. Its environmental benefits are significant, as it reduces the impact on local water bodies, eases the burden on wastewater treatment plants, and minimises pollution to support ecosystem health. Financially, it leads to reduced discharge costs, potential revenue generation from excess treated water sales, and a decreased carbon footprint due to less water transport and treatment.

Beyond immediate practical gains, adopting sewage-to-water recycling signifies a commitment to sustainable practices and helps manufacturing facilities meet evolving regulatory standards. Sewage-to-water recycling has substantial potential for using water resources in manufacturing facilities. Several compelling reasons support the adoption of sewage-to-water recycling. Sewage-to-water recycling provides significant cost savings, reducing reliance on external water sources.

Additionally, manufacturing facilities have social and environmental responsibilities to minimise their impact on surrounding ecosystems. Recycling sewage water helps reduce pollutant discharge into natural water bodies, thereby minimising pollution and preserving aquatic life. Moreover, recycling sewage water buffers against water shortages caused by climate change, ensuring continuous operations even in challenging circumstances.

In conclusion, recycling sewage water provides manufacturing facilities with a long-term, reliable water source amidst increasing water scarcity. It ensures uninterrupted operations and offers benefits ranging from cost savings to environmental stewardship. It represents a step towards a more sustainable future, aligning business objectives with responsible resource management.

Real-time monitoring systems and sensors provide valuable data on flow rates, pollutant levels, pH, and temperature, facilitating automated control systems to optimise treatment processes. Energy-efficient pumps, motors, and aeration systems help reduce energy consumption in wastewater treatment plants, enhancing energy sustainability and cutting operational costs. Modular and mobile wastewater treatment systems with advanced technologies offer flexibility and scalability, enabling quick deployment and adaptation to changing treatment needs.

Water-efficient technologies and practices, such as low-flow fixtures, water recycling and reuse systems, and process optimisation, contribute to better water sustainability in manufacturing operations. Embracing a circular water management approach involves continuously recycling and reusing water in industrial processes to minimise freshwater intake and wastewater discharge.

Efficient water management strategies include smart demand-side management and water harvesting within manufacturing facilities. State-of-the-art energy-efficient solutions can be applied across various processes, from traditional water processing to desalination through reverse osmosis and water and wastewater treatment and distribution. These solutions help conserve precious water and energy resources while fulfilling a significant portion of the energy demand of the complete water cycle.

ZLD systems are crucial in conserving water resources by maximising water reuse and minimising discharge volumes. These ambitious wastewater management strategies eliminate or reduce any liquid waste leaving the plant, with most water being recovered for reuse. Advanced treatment processes support manufacturing facilities’ enhanced contaminant removal, regulatory compliance, and sustainability goals.

Employee training on managing hazardous materials, proper use of protective equipment, and emergency procedures is essential to promote safety and hygiene. Global water scarcity is a significant concern, particularly in manufacturing processes, which are heavy water consumers. By recycling sewage water, these facilities can significantly reduce their reliance on freshwater sources, contributing to the conservation of this vital resource.

=================

Dharmendra Pratap Singh, Chief Operating Officer, Universal MEP Projects & Engineering Services Limited- Voltas.

Adherence to regulatory standards, equipment maintenance, and continuous monitoring ensure reliable and uninterrupted water treatment plant operations.

Shardul Apte, Director – Design & Sales, Goldfinch Evaporating System.

Less water consumption indirectly leads to less wastewater generation, which is segregated for selecting treatment processes to optimise opex costs.

Priyanka Khaire, Deputy Manager, Bioremediation, Organica Biotech Pvt. Ltd.

Sewage-to-water recycling offers manufacturing sites transformative water management. Its adoption can accelerate resource utilisation in manufacturing facilities.

Anil Sethi, Chairman, Pump Academy Private Limited.

Evaluating energy requirements and operational costs, including the consumption of chemicals, additives, or other resources necessary for the treatment process, is paramount.

Chandrashekar Hariharan, Chairman, CII IGBC, Bangalore, and head AltTech Foundation.

Selecting technologies for wastewater treatment in manufacturing sites is complex. Solutions are required for heavy metal contamination and diverse industrial waste challenges.

Mandar Vaijnapurkar, Head of Drives Sales, Marketing & Services, India, Danfoss.

The integration of circular economy principles in wastewater treatment is a forward-looking approach that harnesses the wastewater potential for resource generation.

Rajesh Jha, Country Environment & Sustainability Manager, ABB India.

Advanced treatment processes are vital in enhancing the efficiency and effectiveness of wastewater treatment in manufacturing facilities.

**********************************************************

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.