Digital microscopes replace traditional magnification tools in quality control

By OEM Update Editorial January 14, 2019 2:48 pm IST

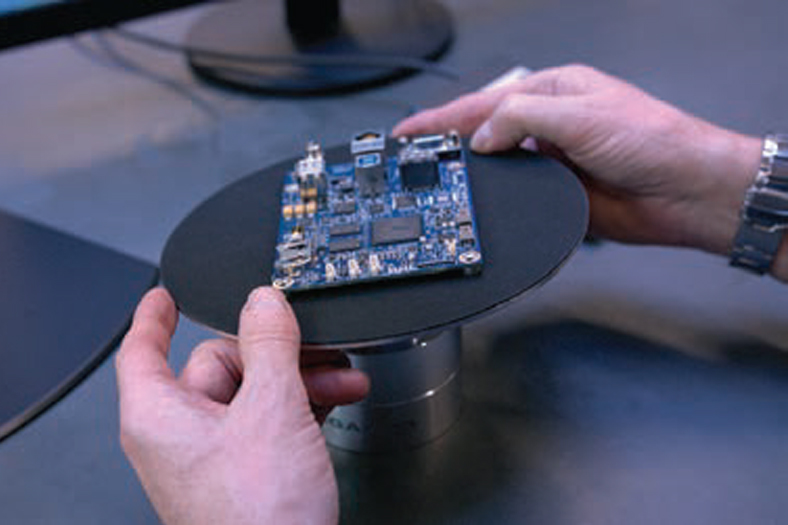

Using a digital microscope instead of traditional magnification tools to repair and/or rework defective boards will improve the operator’s user experience and pave the way for more efficient quality control thanks to the bigger working area and real time image display.

Once a printed circuit board has been identified as faulty during quality control, repairing and reworking will most likely include hand soldering. However, due to the miniaturisation of components in, e.g. smart phones and tablets, traditional tools such as magnification lamps and optical microscopes become insufficient or inexpedient.

Digital microscopes replace traditional magnification tools

Today, higher magnification levels than previously are needed when hand soldering ICs and capacitors due to the increasingly smaller components. However, many operators find that magnifying lamps are no longer able to provide the required magnification levels. Moreover, optical microscopes, usually considered the alternative to magnifying lamps, have a small field of view, creating a limited working area and thus making it difficult for the operator to work under. A digital microscope will also improve cooperation between colleagues by looking at a shared monitor.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.