Automotive: A suspenseful story with a twist

By OEM Update Editorial March 7, 2019 4:19 pm IST

On many passenger vehicles, a rear twist beam suspension system plays a key role in handling performance and driving comfort. Welding these complex components and inserting the necessary bushings is a job that requires extreme precision. Welding specialist, Finearc Systems relies on B&R for the necessary control performance, and also benefited from the time and cost savings of B&R’s integrated development environment.

For many, the daily drive to work is long and frustrating. Yet, especially for those whose commute includes bumpy roads in poor repair, the journey is made considerably more bearable by their car’s suspension system. In many passenger cars, the rear wheels are connected to a type of suspension system called a twist beam – one of the most critical components in determining the vehicle’s handling performance.

These individual components of the rear twist beam must be arc welded together with high precision, making it the perfect job for Finearc Systems. Since its inception more than 30 years ago in Pune, the automotive hub of India, Finearc has established itself as a trusted name in robotics and automated welding and cutting solutions serving a wide range of industries.

From concept and design to manufacturing and installation, Finearc’s professional, highly-skilled team strives to meet the critical requirements and specialised applications of major global players across a wide variety of domains, including automotive, pumps, valves, aviation, construction and many others.

Bush pressing made easy

The rear twist beam (RTB) is a critical component in determining handling performance, particularly of passenger vehicles. As an assembly comprised of many separate parts that must be welded together with great precision, the RTB is also highly complex. The RTB assembly line encompasses multiple six-axis robots performing various welding activities.

Once the RTBs have been assembled, they are subjected to quality inspection before entering the final, critical station in the assembly line: the press station, where the bushes are inserted. After this station, the rear twist beam is then ready to be mounted in the passenger car.

RTBs are loaded onto the bush press station manually. Once the machine is in operation, safety curtains provide the necessary protection for the operator. The bush pressing process is not fast, but it does require a lot of accuracy. The bush press machine has an innovative floating design, it allows the component to be aligned with the bush on the pressing axis, giving our users the desired flexibility and reducing costs.

Errors reduced to zero

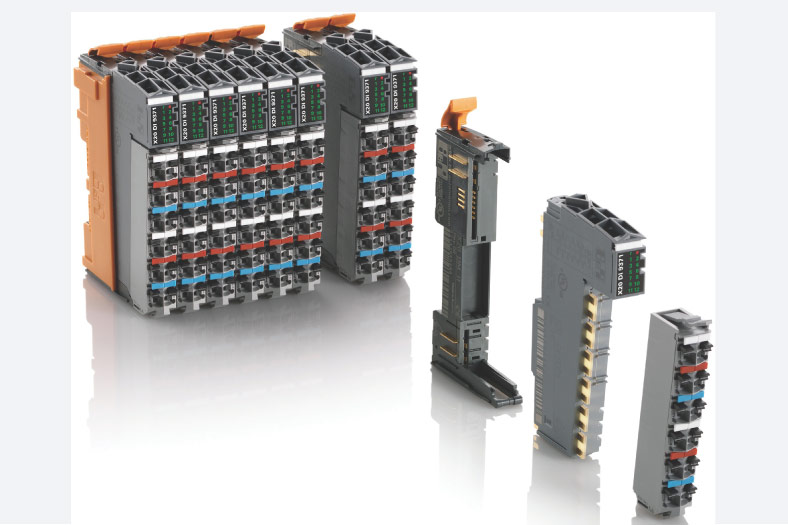

“We evaluated many control systems,” reports Meenal Kelkar, Head–Supply Chain Management, Finearc Systems, “and our technical team was thoroughly impressed with the performance of B&R’s systems. The accuracy achieved was outstanding and we have zero errors in measurement.” Load cells can be connected directly to the X20 analog input module and provide pressure feedback directly to the controller, increasing accuracy and reducing the number of field components required.

During the bush pressing process, the controller records the pressure values with respect to the movement of the bush, and the resulting curve is mapped against set threshold values to ensure quality. This is then linked to a unique bar code, which is printed and adhered to the RTB to provide component and quality traceability.

Masters of integrationThe pressure-displacement curves are displayed graphically on a B&R C-Series Power Panel, which serves as an integrated HMI and PLC unit. One of the challenges as a machine builder is handling the various protocols available in automation. The variety of interface options available on B&R’s Power Panel gives the desired flexibility.

B&R also offers a single tool – Automation Studio – for programming every aspect of the automation system. That makes developing and maintaining different versions much easier for the software developers. Finearc can also use a single backup for multiple projects. This has drastically reduced an effort in commissioning and after sales service.

In addition, mapp Technology components available in automation studio have been instrumental in reducing the programming costs and development time. The real-time, vendor independent Ethernet POWERLINK protocol acts as the communication backbone in B&R systems, offering high performance while at the same time reducing cabling and maintenance effort.

Going beyond

“We have over 50 years of experience in welding applications and we are proud to say that we are technical experts in our field,” says Kelkar. “By combining that expertise with B&R’s technology leadership in industrial automation, we will take our welding and cutting applications to new heights. We look forward to continuing our collaboration with B&R through many new and challenging applications.”

Shrikant Pathak, Managing Director, Finearc Systems says, “Partner with us, when you need to be more efficient, productive and competitive. From concept and design to manufacturing and installation, our professional, highly-skilled team strives to meet the critical requirements and specialised applications of global majors across varied industry domains including automotive, pumps, valves, aviation, construction and many others.”

Kelkar, says, “B&R is a technology leader in industrial automation and combining B&R technology with our expertise, we are sure of attaining greater heights in areas of welding and cutting. We wish to take our association with B&R to a new level and look at numerous new and challenging applications.”

Authored article by:

Shrikant Pathak,

Managing Director,

Finearc Systems

Meenal Kelkar,

Head – Supply Chain Management,

Finearc Systems

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.