Automation and IIoT driving sustainability at work

By OEM Update Editorial June 9, 2023 2:42 pm IST

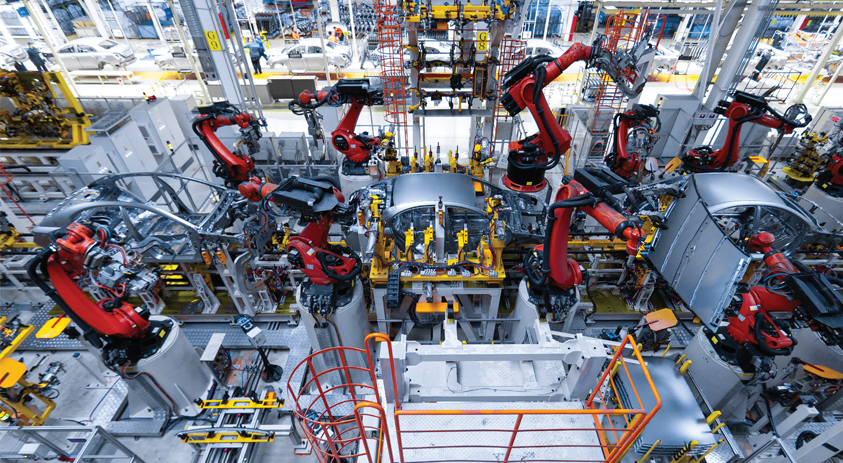

In pursuing sustainable manufacturing and improved performance, companies are adopting advanced automation and IIoT technologies to optimise resource utilisation, reduce waste, and minimise environmental impact.

Companies prioritise secure access to accurate and up-to-date data in the industrial sector. To stay competitive and improve overall operations, businesses invest significantly in advanced manufacturing software solutions. These solutions leverage cutting-edge technologies to enable smarter and interconnected factory operations. This empowers manufacturers to tackle major challenges like minimising downtime, reducing unexpected failures, improving changeover efficiency, and implementing real-time data-driven predictive maintenance.

In pursuit of a decarbonised society and reducing emissions during production processes, Yosuke Ishizaka, Managing Director of Fuji Electric India Pvt. Ltd., suggests that all departments should align and integrate sustainability into their operations. He emphasises the interconnectedness and mutual benefits of innovation and sustainability. Amol Bari, Head of Services Business at Pilz India, emphasises that sustainability is a fundamental principle, and energy efficiency is a specific requirement for new product development by the company’s development department. By considering sustainability early in the product lifecycle, businesses can reduce costs.

Yosuke further states to adhere to initiatives that mitigate environmental impact. Promoting the 3Rs: reduce, reuse, recycle, and seek opportunities to minimise environmental impact throughout the product lifecycle, simplifies compliance requirements and ultimately benefits manufacturers.

Maximising resource efficiency and environmental footprint

Manufacturers can enhance performance by adopting automation, IIoT, VR, and other technological advancements. These technologies enable the utilisation of real-time data to optimise manufacturing processes, predict equipment failures, and improve supply chain management. They also offer benefits such as reduced costs for physical prototypes, enhanced quality control, virtual design, training, and collaboration. As a result, businesses can operate more efficiently, cut expenses, and improve product quality, optimising, thus increasing their competitiveness. Manoj Brahme, Director of SDTronics, emphasises that these technologies enable companies to reduce the time required to bring new products to the market, thus maintaining their competitiveness.

To optimise resource utilisation, the best approach is, to begin with process optimisation. Himanshu Sharma, Head of Marketing and Corporate Communication at B&R Industrial Automation, highlights that implementing automation solutions and leveraging IIoT technology allows factories to gather data from various processes and make necessary optimisations to enhance manufacturing efficiency. Real-time data monitoring provided by automation products assists manufacturing units in reducing waste and energy consumption.

Waste and energy consumption can be minimised by effectively controlling and optimising resource consumption through remote monitoring. Sameer from RedLion supports this idea, emphasising that real-time remote monitoring of all resources helps reduce waste and energy consumption. Technology is crucial in maximising resource utilisation and reducing environmental impact through various means. These include promoting energy efficiency, implementing sustainable agricultural practices, advocating for green transportation, and adopting renewable energy sources. Manoj emphasises that technology enables better waste management, water conservation, monitoring of emissions and environmental health and promotes a circular economy while optimising building operations. Embracing these practices can lead us towards a more sustainable and environmentally friendly future.

The Industrial Internet of Things is instrumental in optimising resource utilisation and minimising environmental impact. Amol strongly believes that IIoT enables manufacturers to gather real-time data, monitor energy consumption, and identify areas of inefficiency.IIoT and other technologies have empowered manufacturers to implement predictive maintenance strategies, reducing equipment failures and improving overall effectiveness. By analysing received data, manufacturers can make informed decisions that help reduce resource consumption, minimise waste generation, and enhance sustainability. This technology contributes to reducing downtime, maintenance costs, improving equipment reliability, and achieving better asset utilisation, ultimately leading to increased profitability. Technology also plays a crucial role in optimising resource utilisation and reducing environmental impact by ensuring the safety of humans, machines, and the environment through automation in plants and machinery.Enhancing Manufacturers’ Performance through Automation and IIoT

Industrial automation technologies have significantly contributed to the sustainability efforts of companies. Technology advancements have greatly improved manufacturers’ safety performance. By integrating IIoT enabled automation products, manufacturers can access industrial data and optimise production through immediate action. These upgraded technologies increase the shop floor’s flexibility, enable precise product inspection, accelerate development timelines, and automate repetitive tasks without human intervention. Regarding practicality, Amol highlights using VR technologies to create virtual simulations for machinery safety training and implementing safety procedures and protocols. These simulations provide a realistic and secure environment for workers to learn and practice safety procedures before applying them in real-world settings.

Sameer further explains that machines can be accessed remotely, and data can be forwarded to the cloud. In general, IIoT-enabled automation products offer real-time visibility into data, unlocking significant operational potential in the long run.

Time to adopt technologies

Adopting flexible and intelligent technologies has set a new standard for resource utilisation. Himanshu explains that optimised processes and waste reduction in a production environment contribute to a more environmentally friendly approach, ultimately reducing environmental impact. Substantive, Amol concludes that IIoT plays a pivotal role by enabling real-time data collection from machines and systems, facilitating predictive maintenance and reducing the risk of unexpected failures.

In summary, the significant impact of IIoT and technological advancements has resulted in substantial improvements in manufacturers’ performance. These advancements have enhanced efficiency, productivity, product quality, and sustainability while reducing costs and time-to-market.

“Innovation and sustainability are interconnected and mutually beneficial, following initiatives that mitigate environmental impact.”

Yosuke Ishizaka, Managing Director, Fuji Electric India Pvt. Ltd.

“IIoT aids in optimising resource utilisation and reducing environmental impact, enabling manufacturers to monitor energy consumption and identify areas of inefficiency.”

Amol Bari, Head – Services Business, Pilz India.

“The workers trained in the latest technologies and processes can identify new ways to reduce waste, improve efficiency, and enhance sustainability.”

Sameer Gandhi, Managing Director, OMRON Automation India.

“To sustain leadership in the industry, all stakeholders need to embrace a data-driven approach, enabling informed and timely decision-making.”

Himanshu Sharma, Head – Marketing and Corporate Communication, B&R Industrial Automation.

“The companies’ primary task in the industrial sector is to ensure and secure access to precise and up-to-date data.”

Sameer Mudhalwadkar, Sales Director – Asia Pacific, Red Lions Controls.

“Manufacturers can leverage real-time data to optimise manufacturing processes, predict breakdowns, and improve supply chain management by adopting automation and IIoT technologies.”

Manoj Brahme, Director, SDTronics Pvt. Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.