Packaging sector evolving under the digitised automation era

By OEM Update Editorial September 14, 2019 12:28 pm IST

The impact of digital and automation disruption has felt across the packaging industry. Using digitised information, packaging companies can provide additional services based on customers’ individualised needs. Industry experts discuss the impact of automation and digitalisation in this quick industry analysis.

Adoption of automation and digitalisation platforms will revolutionise the packaging industry. Modified atmosphere packaging (MAP) is a way of extending the shelf life of fresh food products. The technology substitutes the atmospheric air inside a package with a protective gas mix such as CO2. The gas in the package helps ensure that the product will stay fresh for as long as possible and to maintain visual, textural and nutritional appeal.

The controlled MAP environment enables food packaging to provide an extended shelf life without requiring the addition of chemical preservatives or stabilisers. Anil Bhatia Vice President and Managing Director, Emerson Automation Solutions – India says, “Technology interventions can optimise processes in the packing industry. For example, Emerson’s Cascade™ CT4215 Leak Detection System, used on modified atmosphere packaging (MAP) lines to manage the removal of defective packages, even the ones smaller than 0.2 mm diameter, at high speed in real time.”

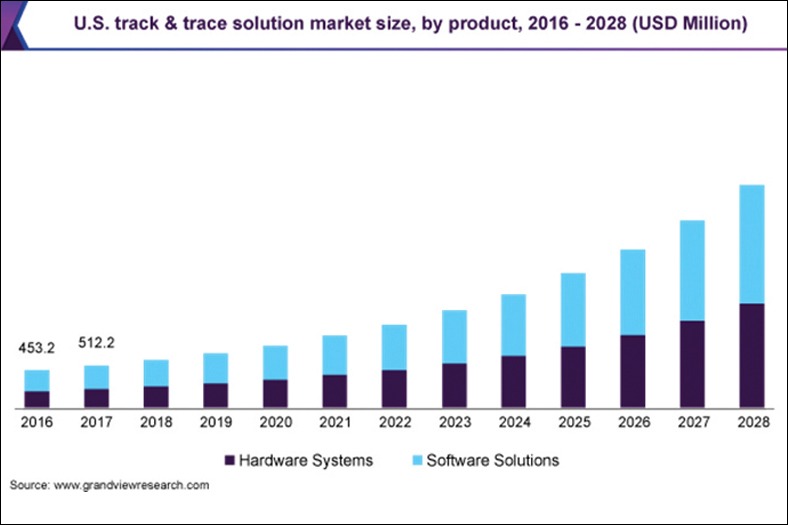

In the fast-paced packaging industry, most machines and factories are automated enabling higher productivity and throughout. However, today we are on the cusp of a new era, where electronics and software will once again change the way we think about industrial process implementation and development. Ninad Deshpande, Marketing Head, B&R Automation says, “Consumers are demanding personalised or individualised products, which are driving demands for shorter runs and faster turnaround times in packaging industry leading to targeted marketing campaigns.” As lifestyles are improving, consumer demands for products quality too have exponentially increased, which has added a greater emphasis on constant product inspection throughout the entire packaging process ensuring an unprecedented level of product security as a basis for overall equipment effectiveness (OEE) calculation. Track-and-trace, human machine safety, diagnostics and predictive maintenance for increasing uptime are also abetting packaging innovations on the shop floor.

Owing to its close interface with FMCG, food n beverage and pharma industry, ‘safety and reliability’ play a crucial role in the packaging industry. Sameer Gandhi, MD, Omron Automation, India says, “Automation is the key to not only ensure the same and at the same time bring significant value additions , it is one of the most dynamic and demanding target industries for an automation player owing to the varied performance indicators and challenges which are not possible to resolve without utilising automation solutions.” This ranges from high levels of product quality to maximum throughput and plant availability to optimum machine efficiency with enormous levels of flexibility and scalability to meet ever-changing customer demands. There is also a stringent requirement of complying with industry regulations, combatting counterfeiting and promoting ethical sourcing and minimizing the impact of recalls.

Addressing these challenges on a real time basis is possible only with customised and fully integrated automation solutions. That’s why it has the potential to revolutionize the sector. In fact, it is already showing good adoption rates. Gandhi says, “Omron’s PackML compliant solutions such as Pick and place robot, mobile robots, cobots, sysmac integrated platform, and traceability application-based solutions are some of the offerings in the portfolio helping packaging OEMs and ends users to excel in operations.”

Integrated automation and digitalisation are enablingmass customisation, increased production flexibility, higher product quality, reduced downtime, minimised wastage and more efficient line integration without compromising productivity, availability and OEE. Various digitisation solutions are enablers for big data analytics and diagnostics, which are enhancing maintenance techniques, resulting in improved production with zero defects, zero breakdowns and zero accidents.

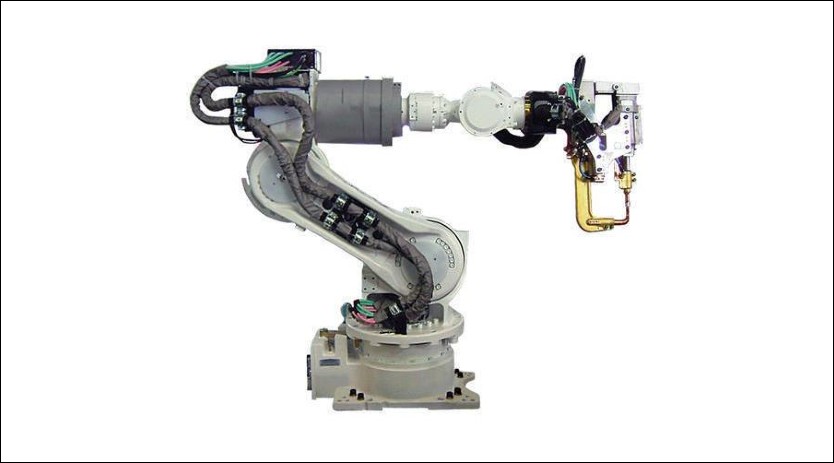

Robotics fitting into package automation

Speed and accuracy are two of the most important indicators which packaging machine makers strive to improve via deployment of automation solutions and this is where robotics comes in. Robotic solutions like parallel robots, mobile robots and cobots increase the speed, functionality and precision of operations. They are used industrial processes to automate placement of individual items into a tray or carton for industries like ready-to-eat foods, beverages, consumer packaged goods, confectionery, cosmetics, pharmaceuticals, and much more. According to Gandhi, they prove useful in performing repetitive tasks with virtually no downtime and can also handle differences in item size and change-overs; ensure items are placed in the proper compartments and keep food safe from contamination as well as maintain aesthetics.

While there are no tangible hazards in deploying a packaging automation solution, per se, over a manually operated machine, there are some challenges in its deployment. According to Gandhi, it starts from choosing the ‘right’ robot (which could be resolved with the help of an able industrial automation provider) to the availability of the right partner eco system followed by cost of implementation and integration with other solutions on the floor. Availability of the desired skills may act as a deterrent too.

Modified atmosphere packaging (MAP) is a way of extending the shelf life of fresh food products.

Anil Bhatia Vice President and Managing Director, Emerson Automation Solutions – India

Greater emphasis on constant product inspection throughout the entire packaging process ensures an unprecedented level of product security.

Ninad Deshpande, Marketing Head, B&R Automation

Complying with industry regulations, combatting counterfeiting, promoting ethical sourcing and minimizing the impact of recalls is the impending requirement.

Sameer Gandhi, MD, Omron Automation

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.