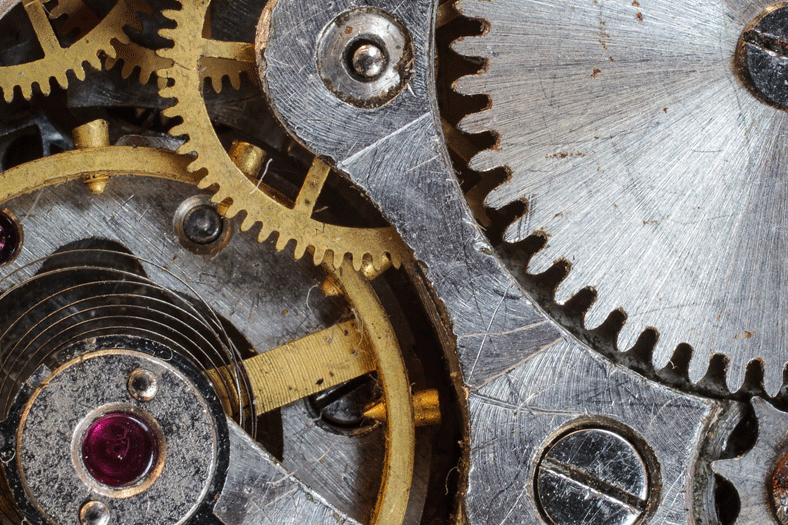

High-end machinery, superior quality in a single step

By OEM Update Editorial October 16, 2019 11:45 am IST

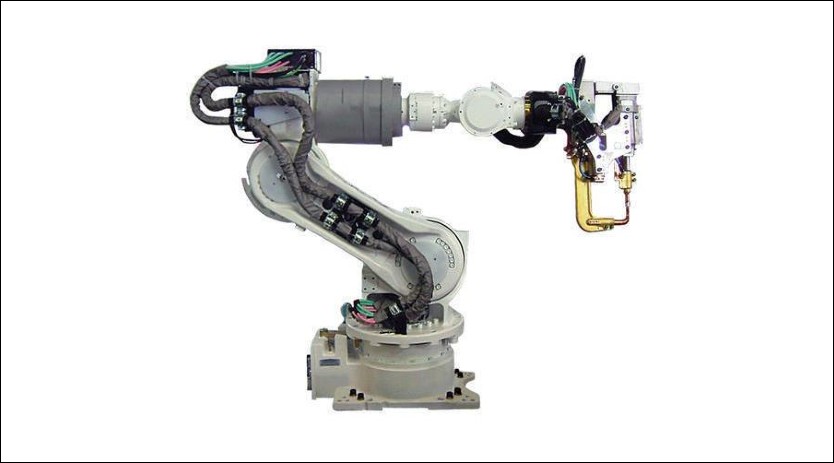

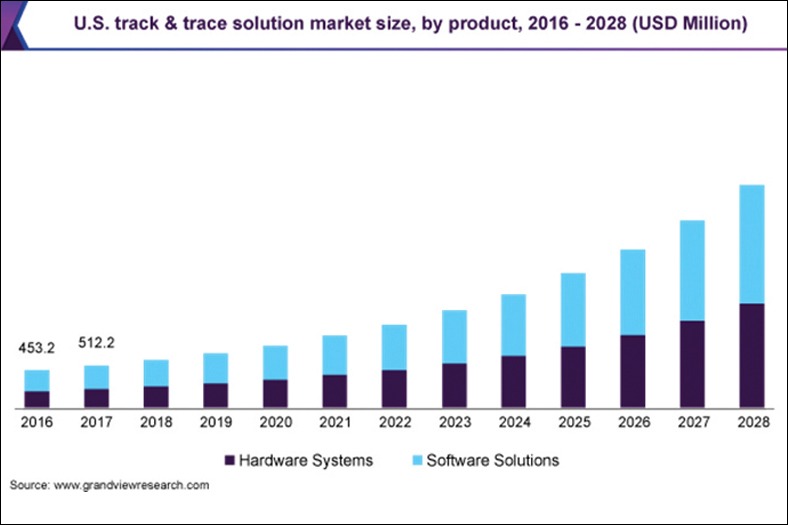

The global push for IoT/ Industry 4.0 concept in manufacturing industries make its mandatory for machinery industry to develop and manufacture indigenous high-end machines that meets high performance and quality standards. This implies that the Indian machine tool industry should review their present control technology and present mechanical design concepts implemented with a target for high-performance output. The demand of high-end machine tools is also growing proportionately.

The machine tool market in India is increasing exponentially day by day. As a result of the growing demand, the country is set to become a key player in terms of global machine tools industry and is likely to see substantial high-end machine tool manufacturing. It is largely expected that the platforms like ‘Make in India’ coupled with the growth in manufacturing are said to be the results of the growing demand in the machine tools sector.

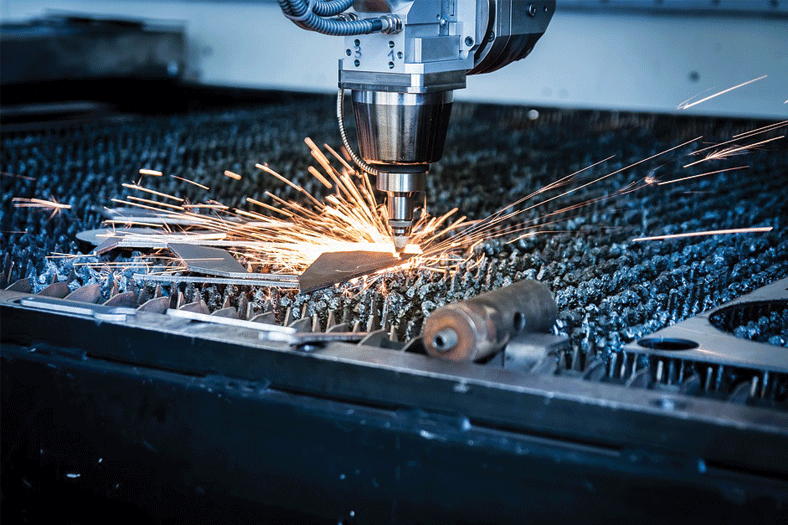

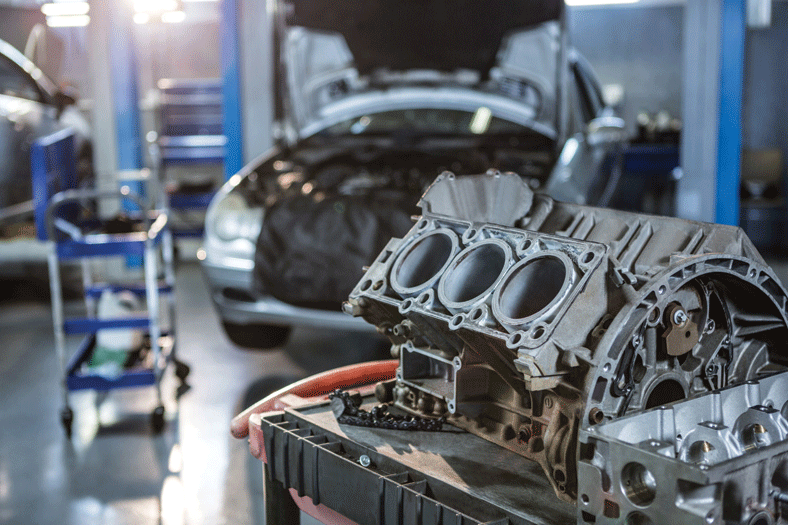

The need for higher performance machine is being pushed which will catalyse and call for very high process capabilities from machines and equipment. The development should be on machines, tooling and the entire manufacturing process for stability and gearing up for higher volume production of high-quality components. Industry will need to adapt to the changing times. Manufacturers will need to change engine technology. This will require re-tooling and the demand for related machinery will increase. Simultaneously the need for light-weighting will remain and so wherever it is possible the re-design must lead to lower weight.

The development of machining technologies and practices over recent years has reached to a level which were difficult to manufacture with required tolerance and quality, can now be attained by much more ubiquitous equipment with added value. A broader picture of change exists outside of the field of machining as manufacturing companies demonstrate a trend to concentrate on core competencies and retain their internal capabilities in design, product assembly and niche skills.

Current status of high-end machinery in India

High-end machine are used barely used in India. The high-end tooling machines are generally very big and highly efficient. Presently, India has around 20 per cent of efficient high-end tooling machines and may increases with the impending demand in aerospace and defence sector. Other industries are least interested in purchasing these high-end tooling machineries as they are expensive and requirement for the same is very low. But considering the changing trends in sports, aerospace and defence sectors, rise of Industry 4.0 and industrial automation the scenario may change in coming years. Big OEM’s like Hero Group, Honda Group, Royal Enfield among others are using such high-end tooling machines.

High-end tooling increases the number of setups of critical job work. Usually, a job is produced after 5 – 7 setups, but with the help of high-end tooling machines the same amount of job with superior quality can be easily produced in a single setup. Because of the appropriate knowledge and awareness available in the aerospace and defence sector where huge and high-end accurate machineries are required; to achieve the same, number of setups is reduced to create easy and fast job work with the application of these high-end tooling machineries.

Import substitution front

Since manufacturing of high-end tooling machines are available in developed countries only, the tooling industry is heavily dependent on imports. There are some Indian companies manufacturing these high-end tooling machines but because of the extensive transit period OEM’s prefer to have imported machinery; this further adds 30 – 40 per cent imports.

For more details contact:

Manoj Sharma

Product Manager

Miranda Tools

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.