Driving and controlling efficiency in systems

By OEM Update Editorial April 13, 2019 12:45 pm IST

When we talk about automation helping the manufacturers, especially machine manufacturers, it is the basic premise of EcoStruxure. Asset optimisation should ensure that the efficiency of the machines to be used the maximum, and alsocustomise the machine to the flexibility of customer requirements.

Today’s world need agility and for that customisation is very important; they don’t want to change the hardware and mechanicals if the requirement changes from a `5 pack to a `3 pack for a packing machine or something similar to that. So, all these things are a part of the automation architecture which is given to the machine builders,to be a one-stop solution and also to provide recipes to customise the output.

Automation aiding the performance of machine control systems

Automation talks about complete optimisation right from the input of the material to the output of the final machine output product. All the elements of the machine along with synchronisation with the backup 1:1 and advisors connected to the machinesgive information on the go about which part is behaving abnormally, where the scarcity of raw material is, what is going right and what is not going right in terms of process right from the manufacturing to printing to the output of the machine. Automation plays a big role in the overall process; connecting it and making it visible to everyone working with it.

Drives for efficient integration in motor control centres

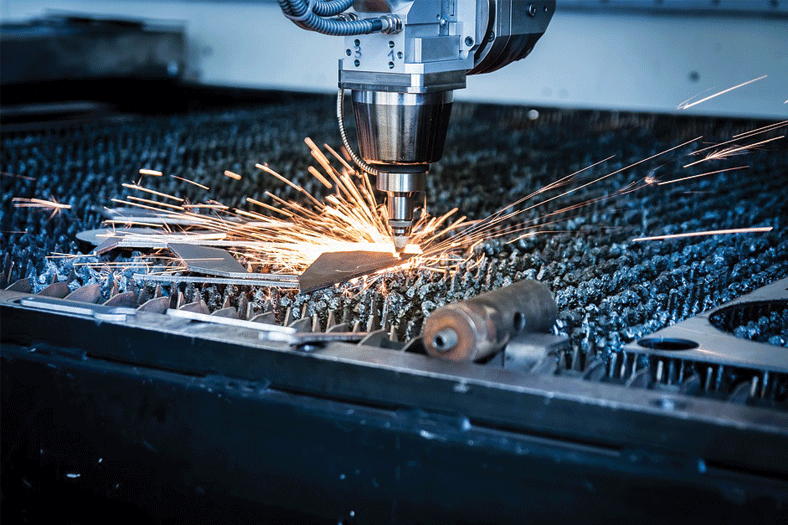

The world is moving from the electromechanical devices to the electronic devices or digital devices. Drives are static converters. Contactors and Relay Logic which were predominantly being used in level 1 of our basic automation, created multiple years back,has been substituted by the semi-solid and the solid state device based architecture, which is now incorporating drive with the technological improvement. Drives not only gives you the flexibility to run the machine at variable speed but removesmultiple mechanical devices like chain and pulley arrangements, gearboxes and improves the efficiency, reliability, ease of operation and Safety. Gears happen to be pretty inefficient in system and world is shifting to gearless operations.

For the machine tool manufacturers, IoT plays a very big role. Industry 4.0 and IIoT are getting much into the root of the machine, bridging the differentiation between what machine manufacturers wants to bring in and also giving value for the end customers. If you take an example of a machine being run, especially for machine tool applications, there are multiple requirements for maintenance and also for tool replacement. Life of mechanicals which are selected with the machine, are now with Industry 4.0 and the EcoStruxure layer built-in; these possibilities exist with remote connectivity. We come to know how many times this tool is required to be changed. It can be around 10 days ahead of time all in respect to the health and the requirement of the continuous procedures for the machines to be done. These act as a very powerful scenario for the machine manufacturers.

One reason for a fact is the world is now moving from machine and the capital equipment to machine or the hardware and service. So, far we have been used to hearing installed software service which is a buzzword but in the coming years, we are going to see the world shifting from the capital to the machine as a service and probablypay/use. So, every hour of usage, for every output which you are getting from the machine, every machine, every tool running on the machine will be connected. We will know everything we can get from the machine; increasing the productivity of machine because of connectivity. The connectivity then comes back to app and analytics in the machine. The hardware and the machine advisors gives us a very good understanding on the asset optimisation or the power being consumed by the machine as well as the functionality and how much we are running eachmachine parts. This is one of the basic premise which is changing the way machine manufacturers are looking at boosting products.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.