Automation: A powerful tool arresting the T&D losses

By OEM Update Editorial September 14, 2019 12:11 pm IST

Most of the automation are deployed in the power segment, right from generation to distribution. Here, industry experts discuss how automation and data acquisition systems can and do contribute significantly to the reduction of T&D losses.

Automation changing the Indian power sector

Technological advancements and innovations driven by rapid electrification, expansion of renewables and digitalisation of the grid are transforming the power sector. The entire business model of utilities is evolving rapidly and state-of-art technologies are gradually making inroads in the Indian power sector as well. Anil Bhatia Vice President and Managing Director, Emerson Automation Solutions – India says, “Electrical power generating facilities are having to change the way they operate due to the increasing amounts of intermittent renewable energy being added to the grid.” More startup and shutdown cycles are now required to manage the constantly shifting energy supply to the grid. Emerson’s Flagship control system, Ovation™, is a distributed control system designed to specifically control operations of a power plant. It helps automate the sequences, optimise load and ensure consistent cycles with minimised fuel usage within the given process constraints, adds Bhatia.

Automation plays a major role in the power sector from generation to distribution. Talking about the power generation, there are large power plants using variable frequency drives with distributed control system. If you look at the distribution point, the sub-stations’ automation plays a very crucial role in the overall efficiency of the power distribution. Various automation players are also engaged at the distribution level offering solutions to consumers in the power conditioning space. Manish Walia, Business Head- Industrial Automation Business Group, Delta Electronics India Pvt Ltd. says, “In this domain, Delta provides variable frequency drives, control solutions, and power conditioning solutions which helps in increasing the efficiency of the existing plants, and upgrading the overall process. Delta Industrial Automation is one of the leading companies in providing solar pump controller solutions to deliver drinking water as well as water for livestock or irrigation purposes by using renewable energy and power which helps in reducing the over stressed load on grid supply. We also contribute in power sector by providing solutions for pumps and fans along with integrating the overall plant process.”

Automation in the Indian power sector is a fairly recent development. Praveer Sinha, CEO & MD, Tata Power says, “While automation at the generation end of the business has been around for some time now; the same at the transmission and distribution i.e. the consumerend is just about picking pace in India.” To begin with, automation improves the efficiency of generating assets. Improved asset performance basically means better use of assets that translates to more reliable services to customers and improved financial numbers too. That is one part of the story.

Automation and the use of digital technology in transmission and distribution have several layers. For example, use of digital technology provides a much better insight into consumer behaviour at a more granular level. According to Sinha the demand-side management in the power industry has seen vast improvement since they got to understand customers better through data. For example, through automation (digital), utilities will be able to match demand and supply better, thereby not only avoiding wastage but also becoming a powerful tool to reduce emissions, thus becoming environmentally more sustainable.

Digital technology also allows greater flexibility and accuracy in customer service. Critical areas from a customer point of view such as meter reading, bill generation, collection, down time servicing, use of smart technologies to help consumers save on energy bills, the areas where digital is now being used can be endless. Today, the application of Internet of Energy (i.e. Internet of Things for the energy sector) helps in reducing downtime and lower operations and maintenance costs.

Using automation in data acquisition systems to significant reduce transmission and distribution lossesEnergy losses occur in the process of supplying electricity to consumers due to technical and commercial reasons. Use of automation technologies and digital platforms can lead to productive improvements, reduce losses and have an energy efficient model. Bhatia says, “The public procurement process in India is still largely based on initial CAPEX cost and not life cycle based. India needs to move to a Total Cost of Ownership based approach with a focus on efficiency and reliability, which will enable decision makers to opt for high-end technology based solutions for an optimal production and utilisation of power.”

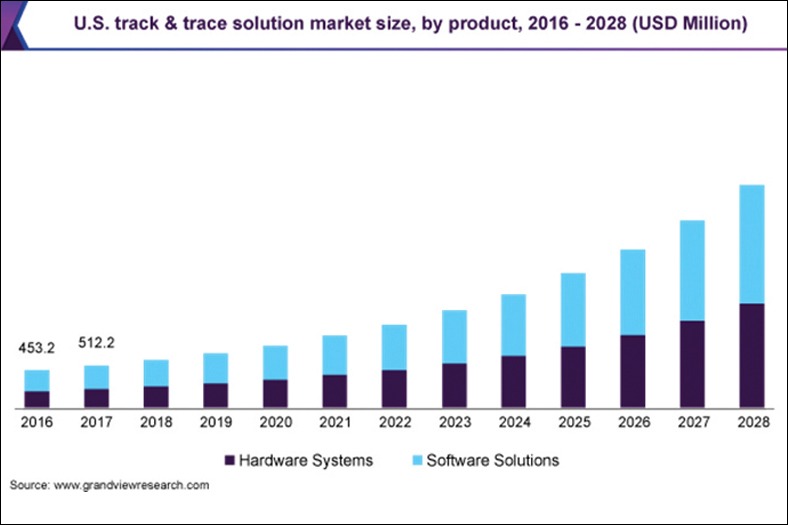

Automation and data acquisition systems can and do contribute significantly to the reduction of T&D losses. Data provides greater transparency in terms of understanding where the leakage is. T&D losses are basically of two types – inefficiencies in the system andthrough under billing (including pilferage and theft). A host of hardware and software solutions are now available to help utilities reduce T&D losses like sensors that can detect tampering of meters, spot surge in energy usage (due to theft), abnormal drop in usage leading to lower billing etc. Sinha says, “Data sourced through digital technologies give utilities better understanding of what is happening in the grid that helps spot sources of T&D loss and take the necessary corrective action.”

According to Walia it’s highly essential to understand the data capturing process and how it is being utilised. It requires a lot of capabilities both at the organisation’s and user’s end. Here, automation plays a major role in data acquisition and help in improving the overall system efficiency.

“Delta provides industrial automation solutions like SCADA, power meters, and industrial energy management systems for providing real-time system control, remote monitoring, production line visualisation, calculate energy consumption and load characteristics which optimise equipment performance, enhance production processes, maximise an enterprise’s energy efficiency and reduce its overall operating costs,” says Walia.

Factors driving the uptake of automation in power industry

Smart metering is one of the factors which will cater the uptake, especially in the industrial and residential areas as there is a high requirement for smart meters in India, and we can see huge business coming in for this sector. Walia says, “Monitoring energy consumption pattern at every level including industry, commercial and residential establishments along with the IIoT is enhancing the need for automation. This smarter system could increase reliability, security, environmental sustainability, asset utilisation and open new opportunities for services and business.”

Technological advancement and increasing demand of renewable energy are another factor which is uplifting the demand of automation products in the power sector. In addition, the guidelines and regulations not only for power factor improvement but for the harmonics level suppression applicable to all DISCOMs will generate a huge demand for automation in power industry incoming times.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.