Adopting a safety-first approach to connected systems

By OEM Update Editorial April 1, 2020 4:36 pm IST

Industry leaders share their views on enhancing their system’s security and its performance through the adoption of latest technologies.

Manufacturing thrives on the efficiency and security of its distribution centres and supply chain management. Security providers have a significant role to play here in identifying potential and non-potential security threats through customised solutions that support the evolving supply chain requirement. Many companies are already harnessing the latest technologies such as automation and robotics, not just for productivity gains, but also as part of safety protocols. Where there is lesser human intervention, there will be fewer human errors during manufacturing processes.

Adopting 3D printing technology for enhanced safety

ERIKS, a global provider of technical components and services, has identified various customised safety parts that to improve the safety of their production facilities. The company has been leveraging 3D printing for the creation of tools to enhance on-site safety. Benjamin Tan, Vice President, Ultimaker Asia Pacific, talks about Ultimaker’s collaboration with an F&B conglomerate, wherein their team set up a 3D printing lab in its Seville plant to improve output, uptime and safety. To enhance safety standards, the team has printed safety latches that are used during machine maintenance. These latches automatically lock when machines stop operating to prevent anyone from accidentally starting a machine while someone is doing maintenance.

Kunal Nandu, Director, Vinay Electrical Solutions says, “Adoption of safety norms is restricted to compliance of basic requirements for major companies. Very few companies are quick in adapting to the latest safety norms and technologies. Manufacturers like us need to evolve with the times and cater to safety measures in order to maintain a safe place. 3D visualisation software is one technology that can create different environments which helps in training the workers of dangers and risks well in advance.“

Available safety monitoring technologies

Tan talks about Ultimaker’s S5 Pro Bundle that comes with an Air Manager with an EPA filter that removes up to 95 percent of all ultrafine particles (UFPs). He says, “Compared to third-party covers, Ultimaker provides a solution for which the ultrafine particle filtering has been independently validated, thus providing a work environment that is free of fumes during the printing process.”

Safety has always been the main priority at Chemical Process Piping, and the company has always followed the rules and regulations set up by the Indian government, says Vijay Rajpurohit, Managing Director, Chemical Process Piping. “We have adopted the main legislations that cover occupational safety and working conditions management at the workplace and we have enforced and followed all the laws which are key for the welfare of the workforce.“ CPP upholds stringent safety standards by using safety equipment like gloves, masks, firefighting facilities, etc. that are certified and upgraded with time, and are available to employees at the manufacturing facilities.

Talking about safety, Suresh Tanwar, Head of Audit and Consultancy, British Safety Council India suggests that capturing unsafe conditions on the mobile phone can help the concerned department to review the site. He states, “Some companies have started using virtual reality (VR) training programmes for appropriate application of safety measures in the vicinity.“ He further emphasised that VR may be the future, but for now, very few companies are using it.

V.G. Sakthikumar, Managing Director, Schwing Stetter India Private Limited, talks about the proposed CAN protocol being implemented in the company. CAN is mainly used for communicating the master and slave modules. Each module contains sensors for monitoring and the information is displayed on the LCD screen. In abnormal situations, it sends a message to other trusted personnel.

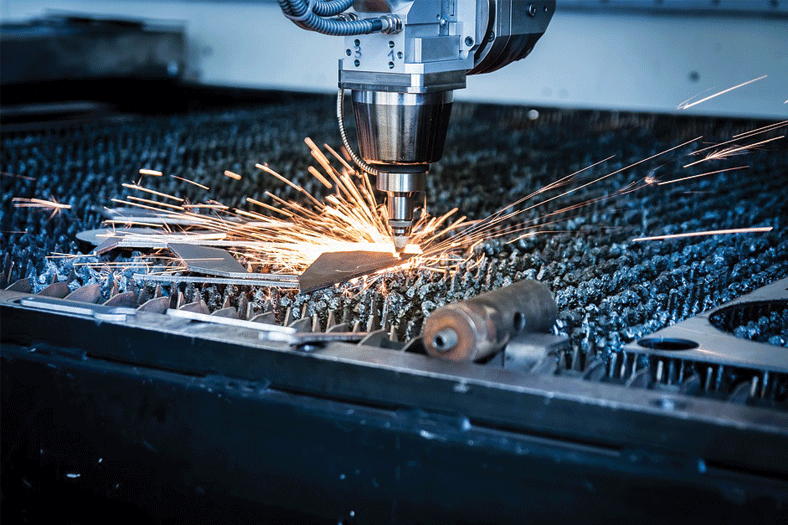

Safety at welding, chemical and fire units

Personal protective equipment (PPE) is one of the vital safety modules to be followed for labour’s safety at intense units. Ultimaker has firefighting preventive measures on material properties, advising users on the proper ways to handle, use or store the different types of materials. Nandu explains the importance of providing PPE to their workers as it involves more risk. Moreover, regular mock drills and frequent educational and training sessions with safety officers can avert any mishaps. Vinay Electrical Solutions provides labels and safety data sheets to workers who are exposed to handling of chemicals in the work area. CPP’s compliance with ISO 45001 certification demonstrates their system for occupational health and safety. CPP workers handle resin systems for the manufacture of GRP piping for which gloves are mandatory. Masks are mandatory whenever any grinding work takes place. Since the resin is prone to fire, adequate fire extinguishers are provided along with periodic training.

Tanwar says, “Emergency preparedness, SOPs, safety training, periodic inspection and safety audits are carried out regularly. Moreover, risk assessment of the work activities is also carried out and workers are involved in the process of risk assessment.” Also, medical tests and health surveillance are done to ensure workers’ health.

Dealing with the peripheral coercions of digital manufacturing facilities

It is very important for machines and factories to adopt secure communication solutions, which have the desired security built into them.Ninad Deshpande, Head – Marketing & Corporate Communication, B&R Industrial Automation

Compared to third-party covers, Ultimaker provides a solution for which the ultrafine particle filtering has been independently validated, thus providing a work environment that is free of fumes during the printing process.

Benjamin Tan, Vice President, Ultimaker Asia Pacific

3D visualisation software is one technology that can create different environments which helps in training the workers of dangers and risks well in advance.

Kunal Nandu, Director, Vinay Electrical Solutions

We have adopted the main legislations that cover occupational safety and working conditions management at the workplace and we have enforced and followed all the laws which are key for the welfare of the workforce.

Vijay Rajpurohit, Managing Director, Chemical Process Piping

Some companies have started using virtual reality (VR) training programmes for appropriate application of safety measures in the vicinity.

Suresh Tanwar, Head of Audit and Consultancy, British Safety Council India

High-level encryption, data protection and database isolation are availed with necessary tools to ensure smooth and safest business practice.

V.G. Sakthikumar, Managing Director, Schwing Stetter India Private Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.