Technology energises collaboration, growth and sustainability

By OEM Update Editorial April 5, 2024 7:08 pm IST

At the world’s leading industrial trade fair, this year’s Hannover Messe, companies from the mechanical engineering, electrical engineering, digital industries, and the energy sector come together to present solutions for a high-performance but also sustainable industry.

At HANNOVER MESSE 2024, themed ‘Energising a Sustainable Industry,’ a wide range of technologies and solutions tailored to diverse industry sectors will be showcased. The exhibition focuses on highlighting innovations that promote energy efficiency, environmental stewardship, and resource preservation across various sectors, emphasising sustainability.

Exhibitors will unveil state-of-the-art technologies, including renewable energy systems, intelligent manufacturing solutions, eco-friendly transportation solutions, sustainable materials, and initiatives promoting circular economies. Specialised pavilions, forums, and workshops will offer opportunities for in-depth discussions, knowledge sharing, and networking among industry professionals, policymakers, and thought leaders.

Navigating the complexities of digital transformation presents a challenge, with operational silos impeding efficiency and delaying the shift towards sustainable practices. The seamless data collection and analysis gap restricts strategic decision-making, limiting the potential to leverage insights for a competitive edge and environmental responsibility.

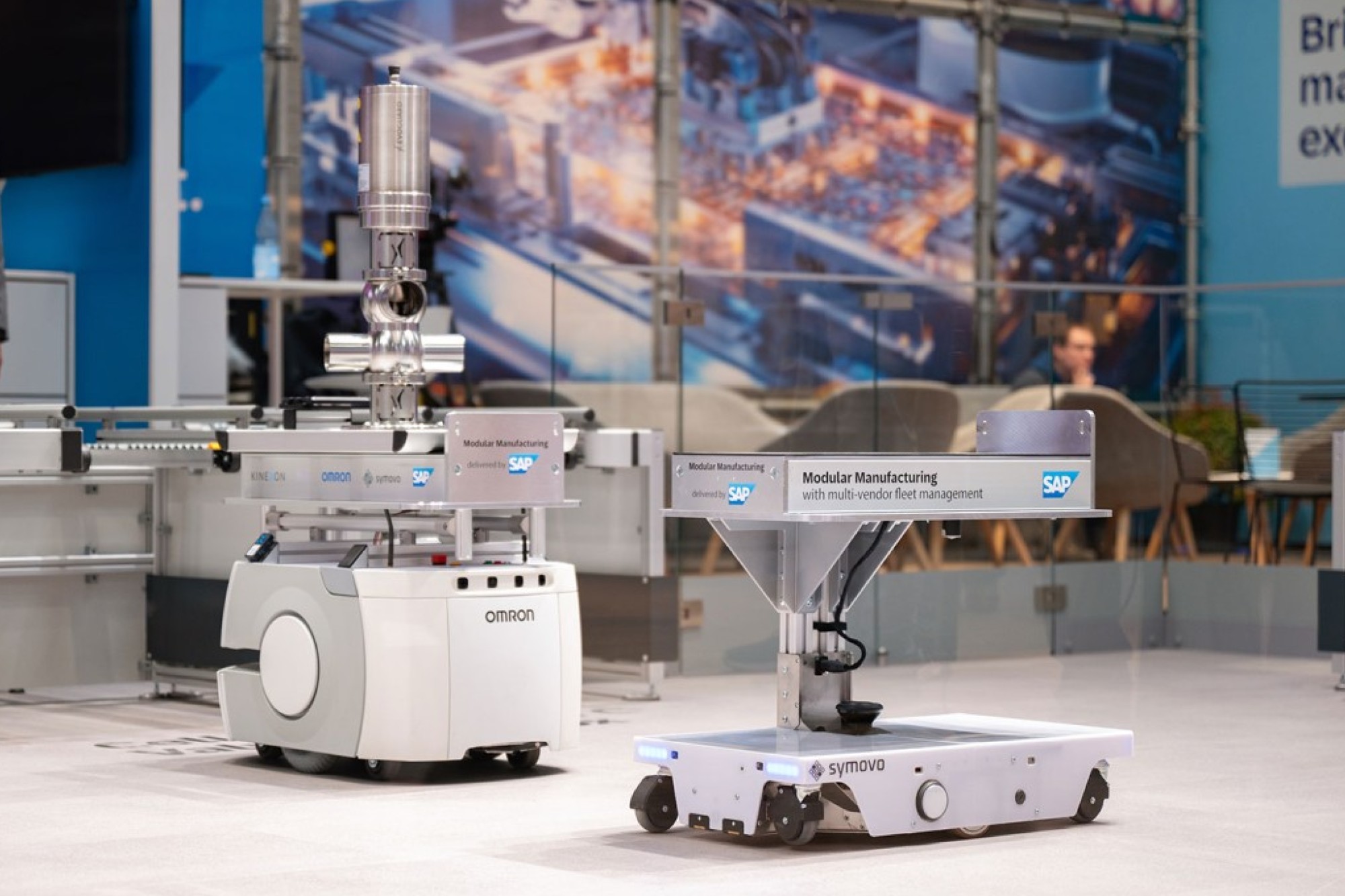

More than ever, industrial companies rely on technology partners to support their growth ambitions, optimisation objectives, and sustainability goals. The future lies in integrating AI technologies and industry-specific software products seamlessly. This means the path to largely autonomous operational management in all application areas is foreseeable. The robot revolution is coming positively, and intelligent robotic technologies are integrated into bending processes.

AI solutions and efficiency

HANNOVER MESSE is set to present a range of AI applications, covering areas such as predictive maintenance, industrial robotics, quality control, supply chain optimisation, energy management, smart manufacturing, and personalised customer experiences. These applications harness AI algorithms to analyse data, streamline processes, and guide data-driven decision-making. Predictive maintenance solutions aim to minimise downtime and maintenance expenses, while industrial robots are deployed to automate tasks and boost efficiency.

To optimise the development and implementation of AI solutions, Resonance, a spin-off of the Karlsruhe Institute of Technology, searches for and finds solutions in AI, big data, and the cloud to support various industries in their digital transformation.

Analog Devices will demonstrate its latest innovations, focusing on technology solutions that enable the next generation of industrial capabilities. The industrial sector must capture new operational insights to realise efficiency, productivity, and sustainability goals.

Automation & sensor technology

SCHUNK enables the automated finger change of grippers during the running process. It comes with the new BSWS-R quick jaw change system, the next evolutionary stage of the BSWS series. The designed system comprises just a few components and is compatible with all grippers with a PGN-plus-P screw-on pattern.

Flexible and stable temperature measurement

WIKA presents the new model T38 digital temperature transmitter. According to the manufacturer, it enables extremely flexible and stable temperature measurement. As a prerequisite, the instrument offers maximum sensor connection combinations and the newly developed True Drift Detection for immediate signalling of deviating measured values.

German machinery manufacturers and Indian industry collaboration

VDMA India is a crucial bridge connecting German machinery manufacturers with the Indian industry through various activities such as networking events, knowledge-sharing platforms, and delegations, all aimed at facilitating business connections and partnerships. Rajesh Nath, Managing Director of VDMA India Services, envisions a future of deeper collaboration between these two entities, emphasising increased innovation, technology transfer, and mutual growth. VDMA India is committed to playing a pivotal role in fostering this partnership by continuing to organise networking opportunities, trade delegations, and knowledge exchange initiatives. Furthermore, the organisation aims to enhance its support services in market reports and business development to strengthen the bonds between German machinery manufacturers and the Indian industry, thereby driving sustainable development in the mechanical engineering sector.

Germany’s powerhouse driving make in india

A key objective of ‘Make in India’ is to increase the manufacturing sector’s contribution to the GDP and, in doing so, accelerate economic growth across the country.North Rhine-Westphalia (NRW), Germany’s most populous state and a leading industrial region, plays a pivotal role in the success and dynamism of the “Make in India” initiative. The €8.3 billion German FDI in India, with NRW making a significant contribution, marks a cornerstone of the economic ties between the two regions. As an industrial powerhouse, NRW is renowned for its robust manufacturing sector, innovative technology companies, and world-class research institutions. This makes it a critical partner in India’s industrialisation and economic transformation quest.

Siemens and Tata Motors JV for EV Drivetrains

The joint venture between Siemens, a global powerhouse in electronics and electrical engineering with strong roots in NRW, and Tata Motors, one of India’s leading automotive manufacturers, marks a significant milestone in India’s journey towards sustainable mobility. This collaboration focuses on developing and manufacturing electric vehicle (EV) drivetrains, underscoring the commitment to electric mobility and environmental sustainability.

Support for Indian companies in Industry 4.0 adoption

ThyssenKrupp, another NRW-based industrial giant, plays a pivotal role in facilitating the digital transformation of India’s manufacturing sector through the adoption of Industry 4.0 solutions. ThyssenKrupp supports Indian companies in integrating smart manufacturing processes, essential for enhancing productivity, efficiency, and competitiveness on the global stage.

HERMES AWARD 2024

An award winner will be announced at the opening ceremony of HANNOVER MESSE on April 21, 2024, which will be attended by German Chancellor Olaf Scholz. Bettina Stark-Watzinger, German Federal Minister of Education and Research, will present the award.

An independent jury comprising top-class experts from political and business communities, academia and society in general, chaired by Prof. Dr.-Ing. Holger Hanselka, President of the Fraunhofer Society, nominated three companies selected from the numerous submissions for the HERMES AWARD: Bosch Rexroth, Schunk and Siemens. For over 20 years, Deutsche Messe AG has presented the HERMES AWARD to one company each year at HANNOVER MESSE. This is the most important international prize in the industry. The award acknowledges a product or solution demonstrating a notably high technological innovation level.

The project nominated is a system designed for the industrial dismantling and recycling of batteries used in electric vehicles. The energy discharged from the batteries is used directly in the process or fed into the power grid. Recycling allows up to 95 percent of the chemical elements to be returned to the production process and thus reused in a targeted manner.

The 2D Grasping Kit project has been nominated. This application kit consists of a camera with lens, an industrial PC, AI software, and an application-specific gripper. What is innovative is the AI-based modelling of component variants and the transfer to a smaller training data set, which reduces recognition training times.

The nominated product is the SiGREEN CO2 management tool. This makes real-time emissions along the entire supply chain transparent, allowing them to be tackled. The system uses actual data instead of statistical averages and allows mapping throughout the supply chain to help decrease the product carbon footprint (PCF). Sensitive data is exchanged across companies within a protected space.

Jury chairperson and President of the Fraunhofer Society, Prof. Holger Hanselka, remarked that once again this year, the applications submitted showcased outstanding creativity and innovative strength. The three nominated products represent the whole gamut of modern production technology issues: automation, recycling, and resource-conserving supply chains. In this way, they demonstrate the importance of manufacturing technologies for a society looking toward the future.

Lastly, the founders of GLOBE Fuel Cell Systems wanted to create something meaningful with the green power to change the world. The result is digitally networked, hydrogen-powered fuel cell systems to support the industry on its way to a CO2-neutral future. And the list of innovations goes on.

More than 4,000 companies will act as an interconnected industrial ecosystem and demonstrate how climate neutrality can be achieved through electrification, digitisation, and automation.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.