Research provides strong impetus for industry

By Staff Report April 3, 2025 3:05 pm IST

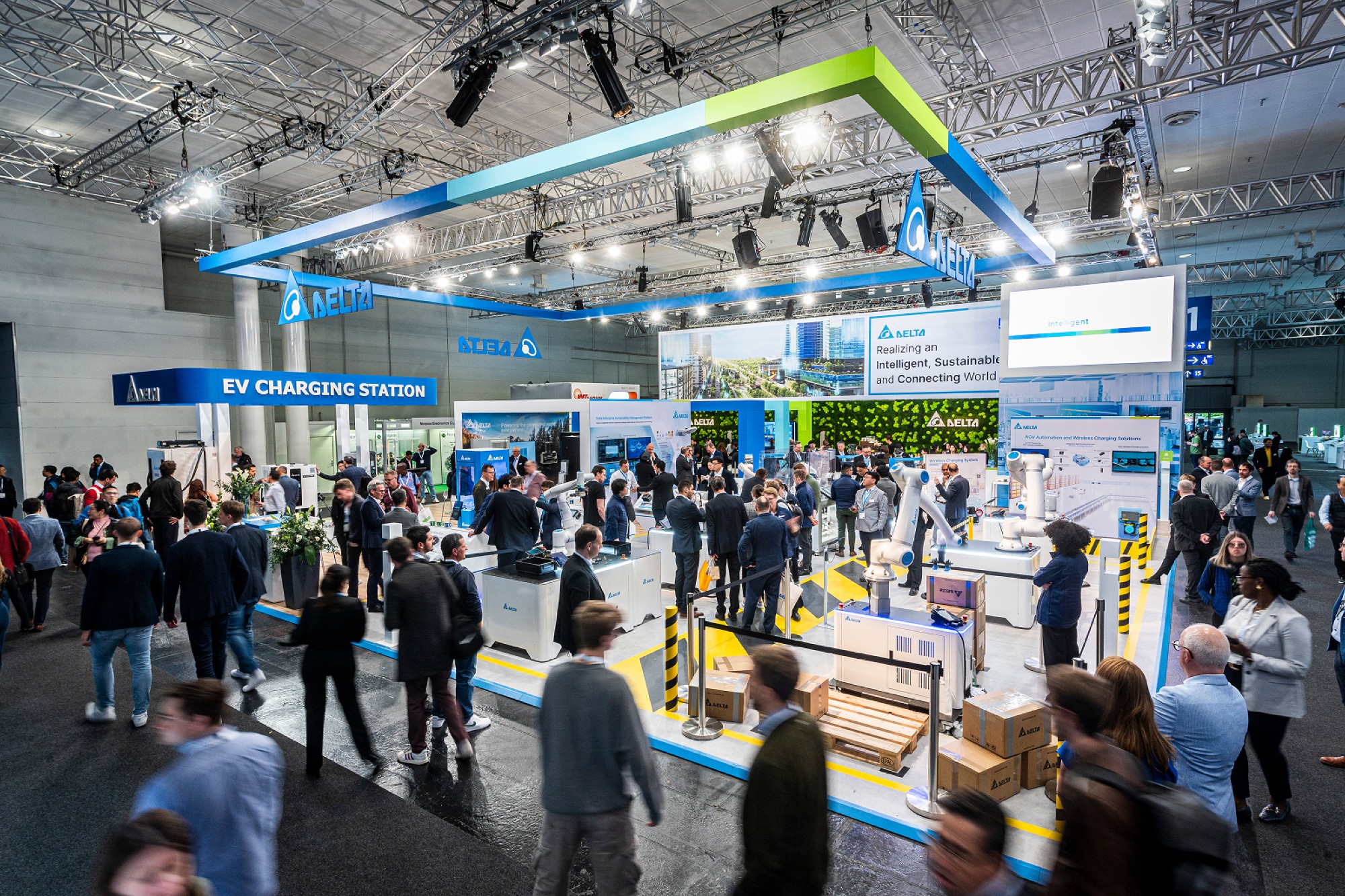

The Fraunhofer-Gesellschaft will once again be represented at HANNOVER MESSE with a joint stand in 2025. Fraunhofer institutes, groups and alliances showcasing 38 exhibits with technological highlights from the fields of production, energy, artificial intelligence and digitisation.

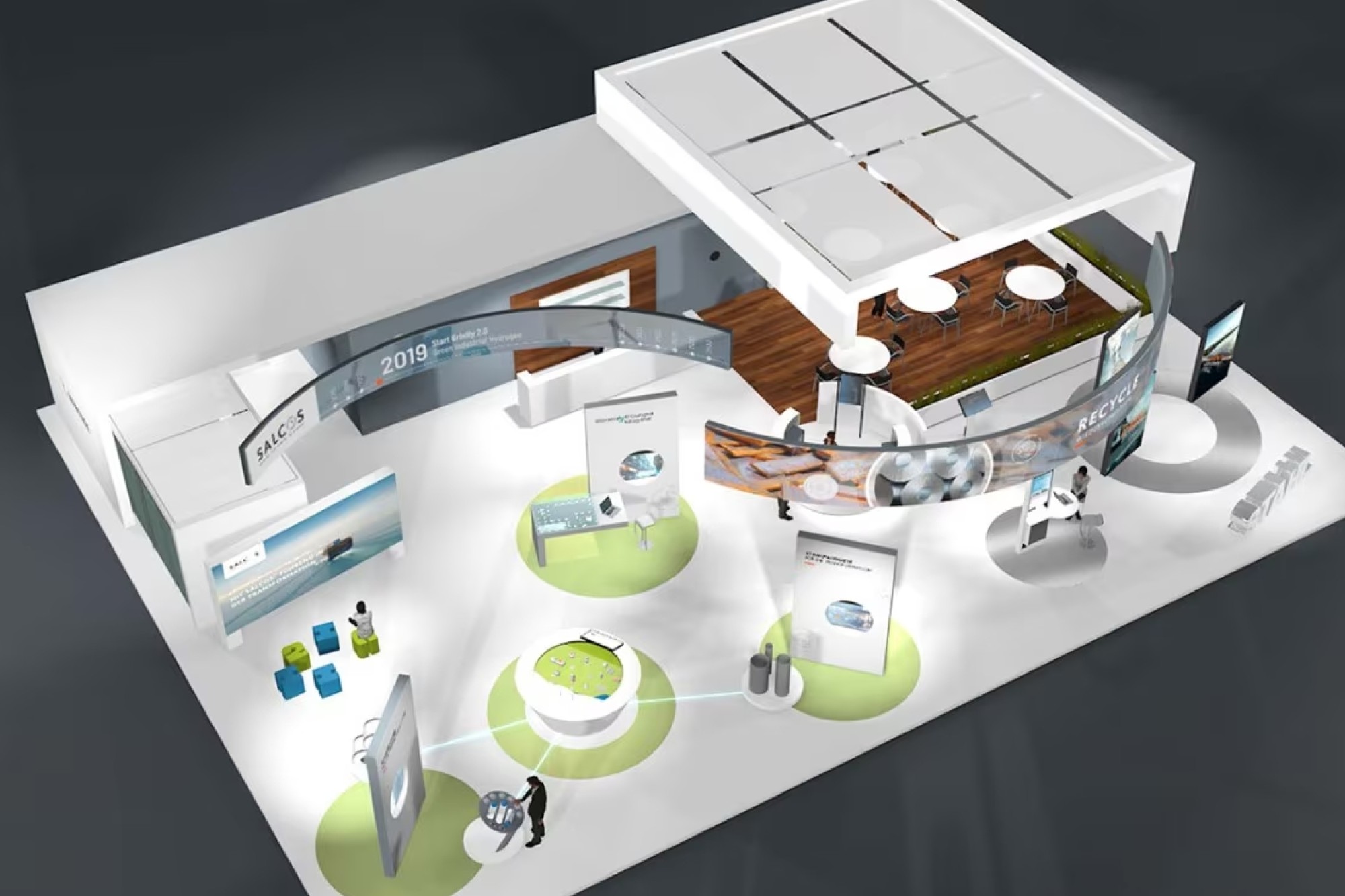

Every year, HANNOVER MESSE is the yardstick for the innovative strength and performance of industry in Germany and Europe. In 2025, the Fraunhofer-Gesellschaft will be present at the world’s leading trade fair for industry with a large joint stand. Under the motto “Innovations for our Future”, 13 Fraunhofer institutes, groups and alliances are presenting their innovations and technologies. A total of 38 exhibits from the three thematic areas of AI for Industrial Innovation, Energy Solutions and Circular Economy, and Smart Systems and Materials Efficiency.

The aspects of sustainability and resource conservation

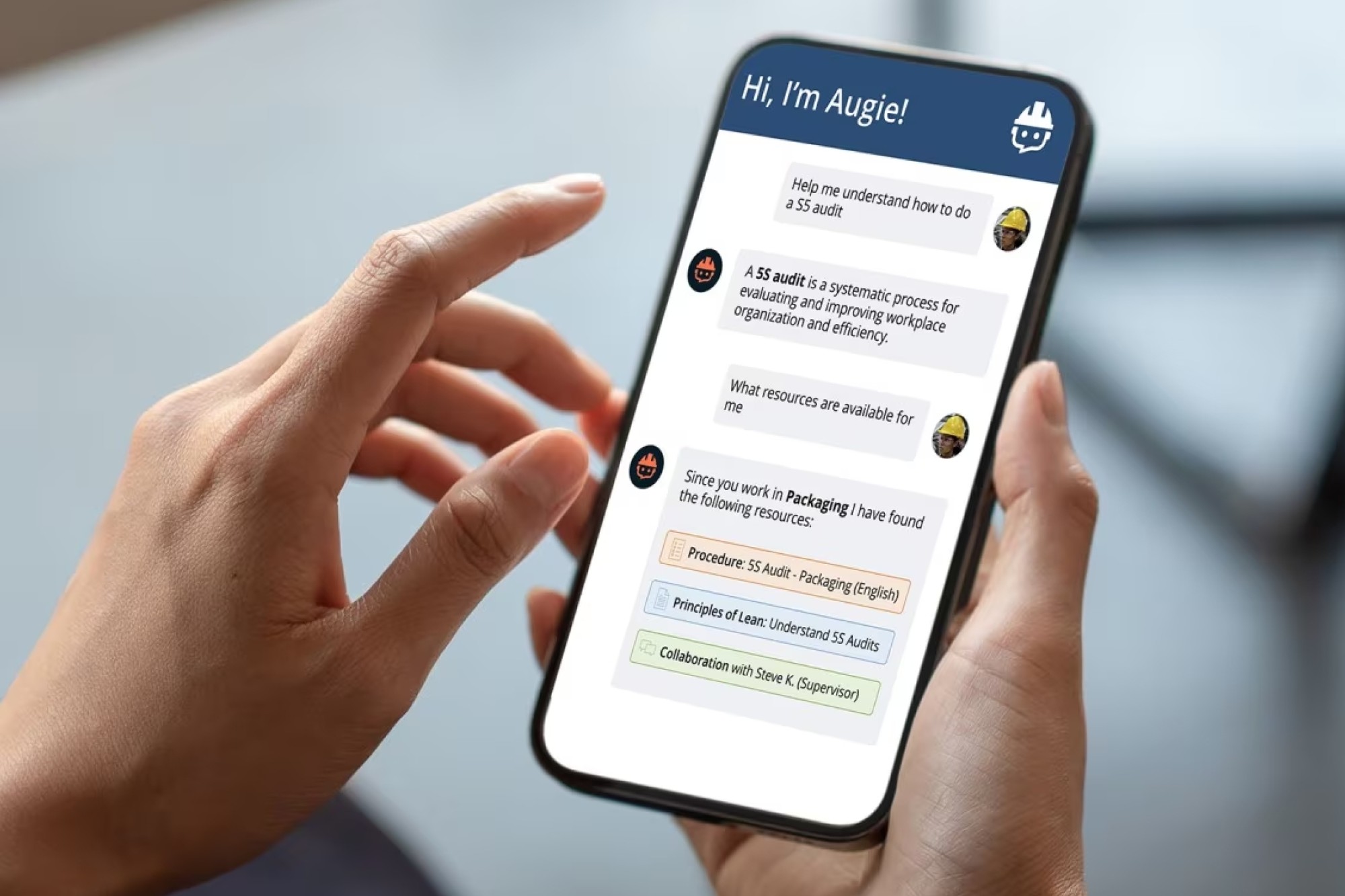

The exhibits demonstrate how forward-looking innovations are already helping companies to improve their competitiveness today – through optimised processes and innovative products or services. This is especially true in times of great upheaval and challenges in the economy, politics and society. In all of their developments and solutions, the Fraunhofer researchers consider the aspects of sustainability and resource conservation. In the field of artificial intelligence, the Fraunhofer Institutes are presenting concepts that already offer real added value today. For example, AI helps companies to accelerate processes and make them more efficient. Small and medium-sized companies also benefit from this.

Highlight exhibits

The highlight exhibits represent key technologies that mark the state of the art in terms of what is technically feasible. These exhibits, selected for each topic area, are marked by a glowing cube at the booth.

Reliable AI for production monitoring

Artificial intelligence can make production processes more efficient and error-free, but many companies are still hesitant. How safe is AI? On what basis does it make decisions? And who is liable in an emergency? Using the example of quality monitoring for the robot-based insertion of expansion nuts, Fraunhofer IEM shows how AI can be used reliably in production and what added value it creates.

3D components manufactured at high speed

The Fraunhofer Institute for Laser Technology ILT has further developed extreme high-speed laser material deposition (EHLA), which was originally designed as a coating technology, for additive manufacturing (EHLA3D). According to the researchers at ILT, the advantages are the construction of thin-walled elements and the processability of materials that are difficult to weld, as well as near-net-shape additive manufacturing and even repair.

Cyclometric: recyclable products

The Fraunhofer Institute for Industrial Engineering IAO is presenting “Cyclometric”, a software platform and methods for the sustainable and cycle-orientated development of products. These make it possible to evaluate and optimise the recyclability of a product or component right from the initial design phase.

Green hydrogenThe Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT is presenting information on the topic of green hydrogen: a video table offers visitors the opportunity to interactively explore the production, use, and storage of green hydrogen.

Edge Cloud Continuum for production

In the Fraunhofer Cluster of Excellence Cognitive Internet Technologies (CCIT), more than 20 Fraunhofer institutes are working on technologies and infrastructures for digitised production. The Edge Cloud Continuum project combines sensor technology, edge computing and AI-supported analyses to enable resource-saving and economical production by using production data.

From plastic waste to 3D printing

Researchers at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research IFAM, together with the University of Applied Sciences in Bremen, have developed a process for using recycled plastics for 3D printing. The plastic granulate obtained in this way has a purity level of almost 100 per percent and can be used in a 3D printer to manufacture components.

Wind turbine made of wood: Wind of change tower

The “Wind of Change Tower” in the northern Swedish city of Skara is 150 metres high and thus the tallest wooden tower for wind turbines in the world. It consists of modules that are glued together on site. Compared to concrete or steel structures, the wooden construction enables CO₂ savings of up to 90 per percent. The Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut, WKI, supervised the bonding of the wooden tower. The exhibit shows a replica of the wooden tower.

Exhibit for citizens: future energy

This interactively designed exhibit takes laymen on a journey around the topic of hydrogen. Visitors follow a molecule on its way through the various stages – water, hydrogen and energy. The exhibit represents an important part of the Fraunhofer mission: the transfer of knowledge to society.

Hydrogen solutions in hall 13

In the special topic area “Hydrogen + Fuel Cells EUROPE” in Hall 13, nine other Fraunhofer institutes and facilities are presenting solutions related to hydrogen and the hydrogen economy.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.