AI as a driving force in industry

By Staff Report March 28, 2025 11:52 am IST

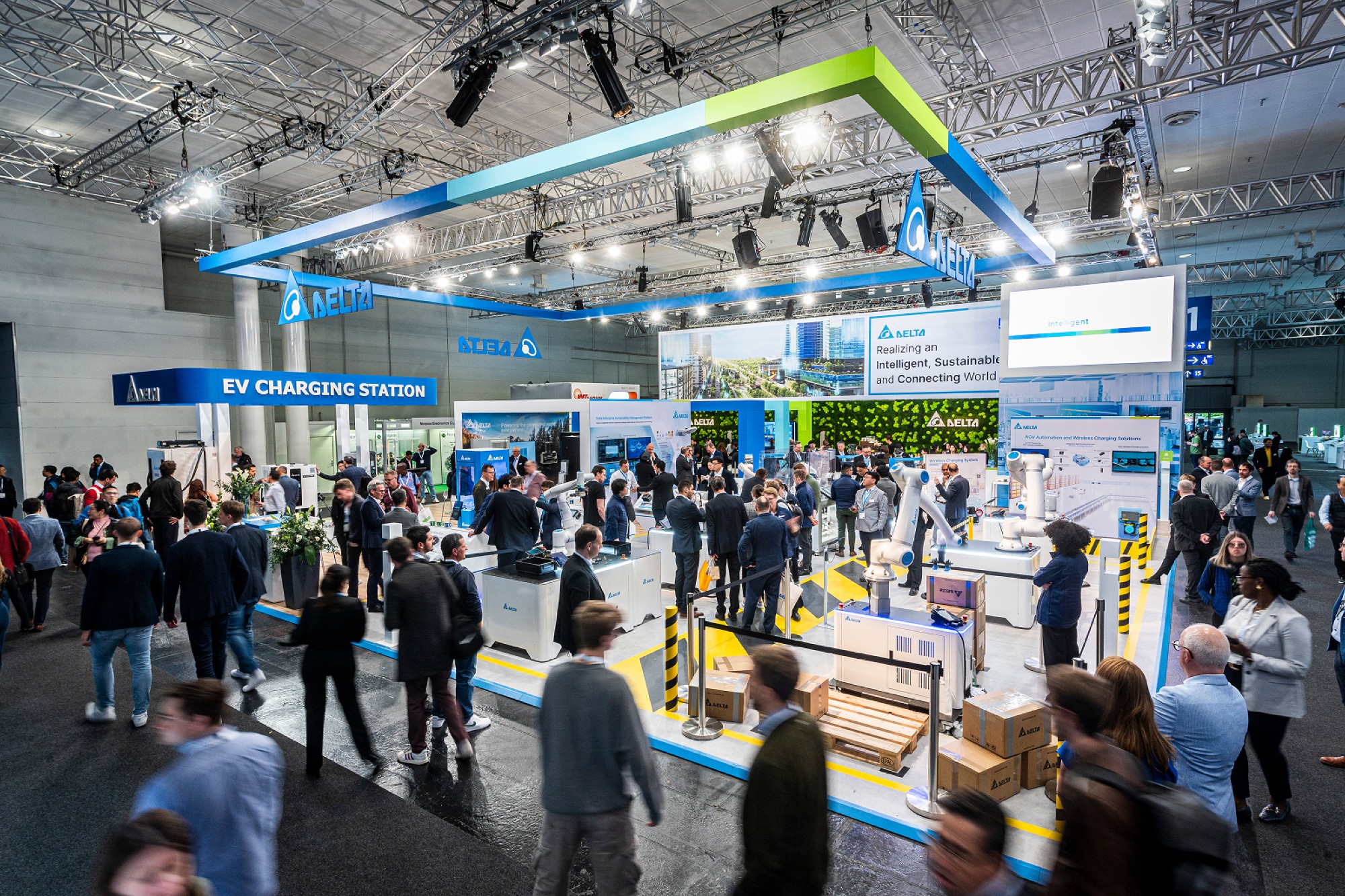

At HANNOVER MESSE 2025, Rittal and Eplan will be demonstrating how AI can help companies to succeed in the future under the motto AI-driven industrial automation is the future.

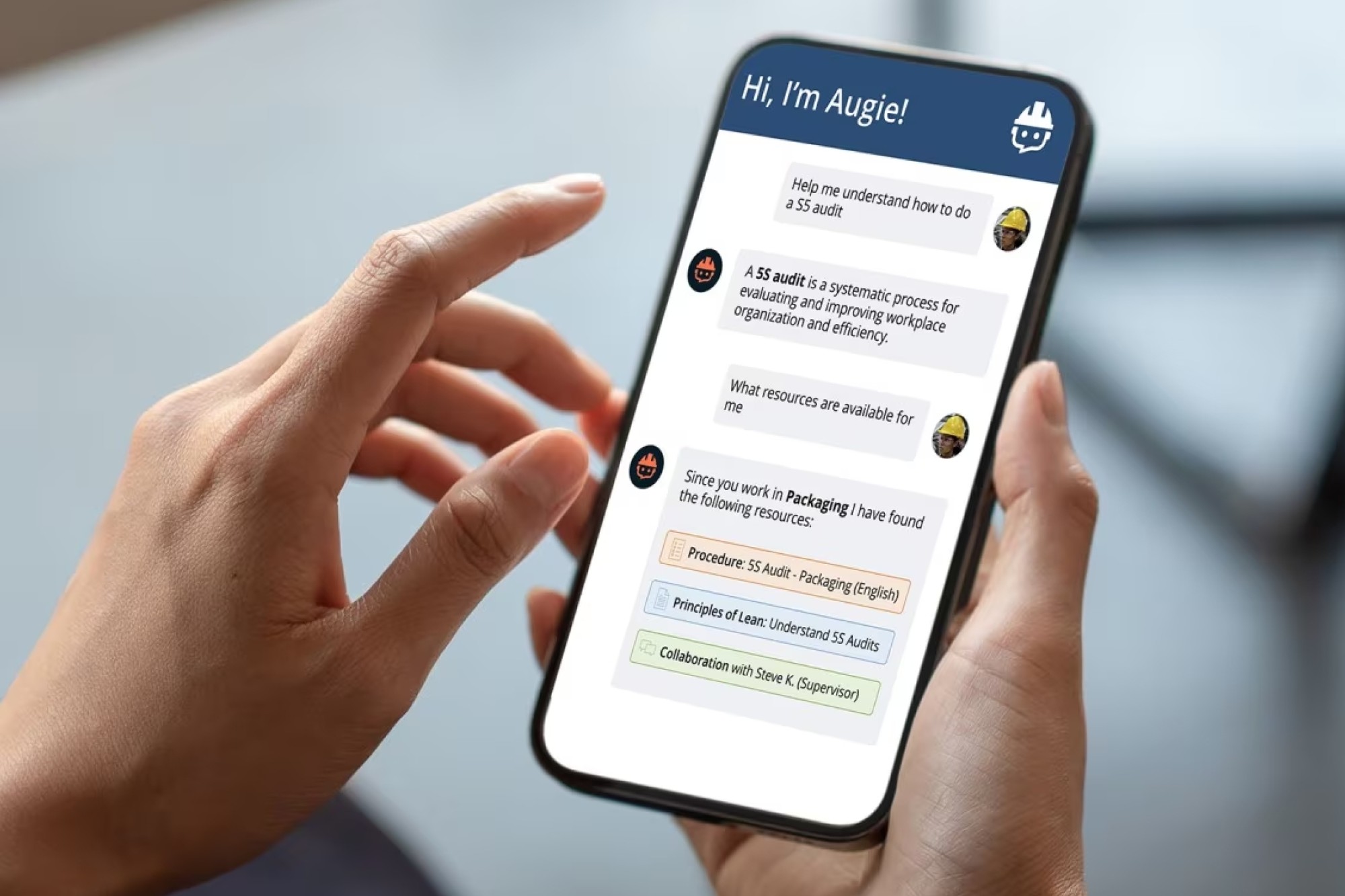

The basis for any automation, right up to the use of AI, is first-class data. This challenge fully meets the requirement that Eplan has already established for years with the Data Standard (EDS) – fully described, standardised article data. The Eplan Data Portal includes more than four million data records for users. In addition, Eplan will be presenting the upcoming Eplan Platform 2026 in Hannover. As a preview, visitors get a first glimpse of functional enhancements to the engineering solutions.

Is your IT infrastructure ready for AI?

HANNOVER MESSE 2025 showcases a wide range of AI applications that promise revolutionary benefits for business. But are the data centres ready? Computing power and power density for AI mean breaking new technological ground because the physical limits of established air cooling are being exceeded. Rittal is showcasing a new coolant distribution unit (CDU) that provides over a megawatt of cooling capacity with direct chip cooling based on water, thus enabling data centres to run AI applications for the first time.

New standard speeds up power distribution

The digital transformation and the energy transition require a great deal of electricity, which is why the new system platform RiLineX is designed to accelerate the construction of power distribution systems, for example in panel building and switchgear manufacturing, with time savings of up to 75 per percent during assembly. At HANNOVER MESSE 2025, Rittal is presenting eight new complete boards in the most common control cabinet widths for 550 amps and 800 amps, or 380 kilowatts and 500 kilowatts. With a consistent platform approach, the company is driving international standardisation and has initiated an ecosystem of technology partners who develop components ‘Ready for RiLineX’, which contacts the board directly. In Hanover, Rittal is introducing new partners who cover a wide range of future-proof applications for alternating and direct current.Machines for copper processing

The new products also include copper processing machines from Rittal Automation Systems, such as the Bending Terminal BT 20E and new system enclosures. The new AXE IT Nano DC, for example, protects the growing IT infrastructure, such as servers and switches, in harsh industrial conditions. The AXE compact enclosures are also available in new sizes that are particularly suitable for use as underfloor enclosures or for logistics and conveyor applications.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.