Technology aiding power circularity and a closed-loop supply chain

By OEM Update Editorial June 15, 2024 4:54 pm IST

Abhishek Agashe, co-founder and CEO at Elima, advocates for the adage “what goes around comes around,” applying it to the concept of “closing the loop” in the green revolution. This strategy is more akin to a savvy hack than a mere scheme, and it aims to reduce waste, costs, and resource consumption. Agashe asserts that a closed-loop supply chain can achieve this by efficiently recycling, remanufacturing, and managing materials.

In the business world, “closing the loop” denotes the culmination of activities and the achievement of objectives. However, as the world transitions to a green revolution with a significant focus on sustainability and its context, “closing the loop” strives to reduce waste and resource consumption by changing how products get managed throughout the cycle. Within the circular economy, waste gets reduced as products that we use today will be transformed into raw materials for tomorrow, creating a closed-loop system; according to recent research by CII’s ‘National Circular Economy Framework’ (NCEF), India’s circular economy is anticipated to be worth $2 trillion and create 10 million jobs by 2050.

Closed loop supply chain overview

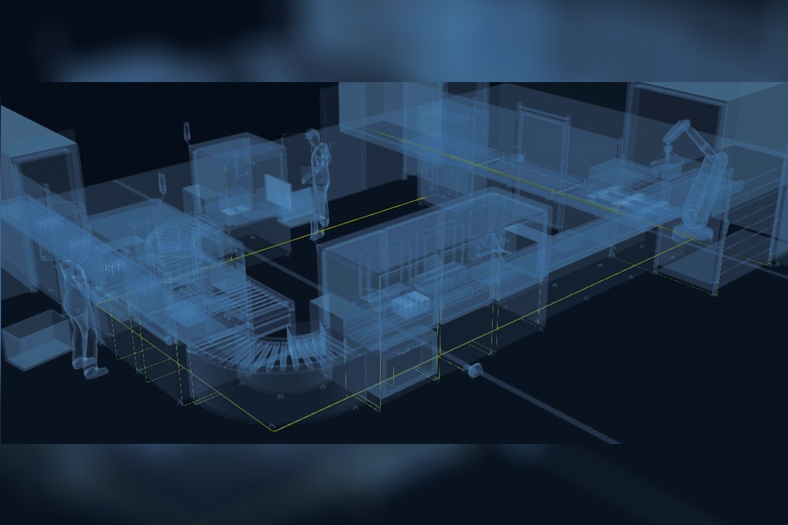

A closed-loop supply chain is where items and components are recycled, refurbished, or remanufactured to generate new products. This cuts down on waste and optimises the use of resources. Adopting such a system is critical for promoting circularity since it allows for the continuous use of materials while reducing the demand for new resources. This approach mandates the engineering of products to be done considering the recycling and use aspects. The materials are meticulously handled throughout their lifecycle to maintain their value and utility.

Overview of closed-loop supply chains

Closed-loop supply chains are becoming increasingly popular for improving sustainability within the circular economy context. The circular concept is linked to a “butterfly diagram,” representing its metamorphosis from caterpillar to butterfly. This transformation alters both its physical appearance and its essential core. Today, with the implementation of the revised EPR policies by the government, it is necessary for companies to include EPR, or Extended Producer Responsibility, into their DNA. EPR is a cornerstone of waste management and sustainable resource usage.

It simply means that manufacturers and producers accept responsibility for the entire lifecycle of their products, including disposal. Implementing EPR programmes encourages businesses to develop products with recyclability and environmental effects in mind. It also incentivises them to invest in waste reduction and recycling technologies, alleviating the burden on landfills while contributing to developing a circular economy where resources are kept in use for as long as possible, maximising their value and minimising environmental harm.

Technology as a catapult to drive the closed-loop supply chainThe future of circularity lies in using technology, particularly AI, IoT, and data analytics. The drive is innovating and restructuring existing linear supply chains into sustainable and circular ones. Technology is guiding us towards a future in which waste is reduced, resources are preserved, and organisations work in harmony with the environment by harnessing advanced data analytics, efficient logistics, and innovative solutions.

Data-driven initiatives are paramount for identifying ways to decrease waste and improve processes. Companies identify places where materials are used inefficiently or squandered by analysing massive statistics collected throughout the supply chain and implementing targeted efforts to solve these issues. Predictive analysis can forecast changes in demand, enabling better inventory management and reducing the risk of overproduction and excess inventory. This supports waste reduction efforts.

Innovative tracking systems, powered by IoT sensors and RFID tags, also enable continuous monitoring of products and materials throughout their journey. This improved visibility allows businesses to work out their reverse logistics, identify inefficiencies, and streamline the return process. The result is cost savings and improved resource management. IoT is prominent in understanding product usage, enabling repair, and scheduling maintenance.

Furthermore, innovative technology-driven waste management systems help firms move from zero-waste to landfill operations. Companies that use advanced sorting and recycling systems can more successfully separate distinct types of garbage, divert recyclable materials from landfills, and reintegrate them into the production cycle. Automated sorting systems employ AI algorithms to identify and separate recyclable items, increasing recycling rates while decreasing contamination.

Supply chain future

The future of closed-loop supply chains and circularity in India hinges on collaborative efforts among stakeholders, technological innovation, policy support, and consumer engagement. India can strive towards a more sustainable and resilient future by embracing the principles of the circular economy.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.