NORD is compacting the gears with smart technology

By Staff Report October 29, 2024 4:58 pm IST

NORD Drivesystems designs compact gear and motor solutions using advanced materials and smart technology. Amit Deokule, Director of Sales and marketing at NORD Drivesystems Pvt. Ltd, shares that their innovations support predictive maintenance and IoT integration, ultimately reducing costs and carbon footprints.

How does NORD Drivesystems adapt to the demand for more efficient and compact gear and transmission systems?

We are responding to the increasing demand for efficient and compact geared drive systems through several innovative strategies. We have developed IE4 and IE5+ synchronous motors, which offer higher energy efficiency and reduced operational costs. These motors are ideal for applications requiring continuous use, such as material handling or conveyor systems, where energy savings are critical.

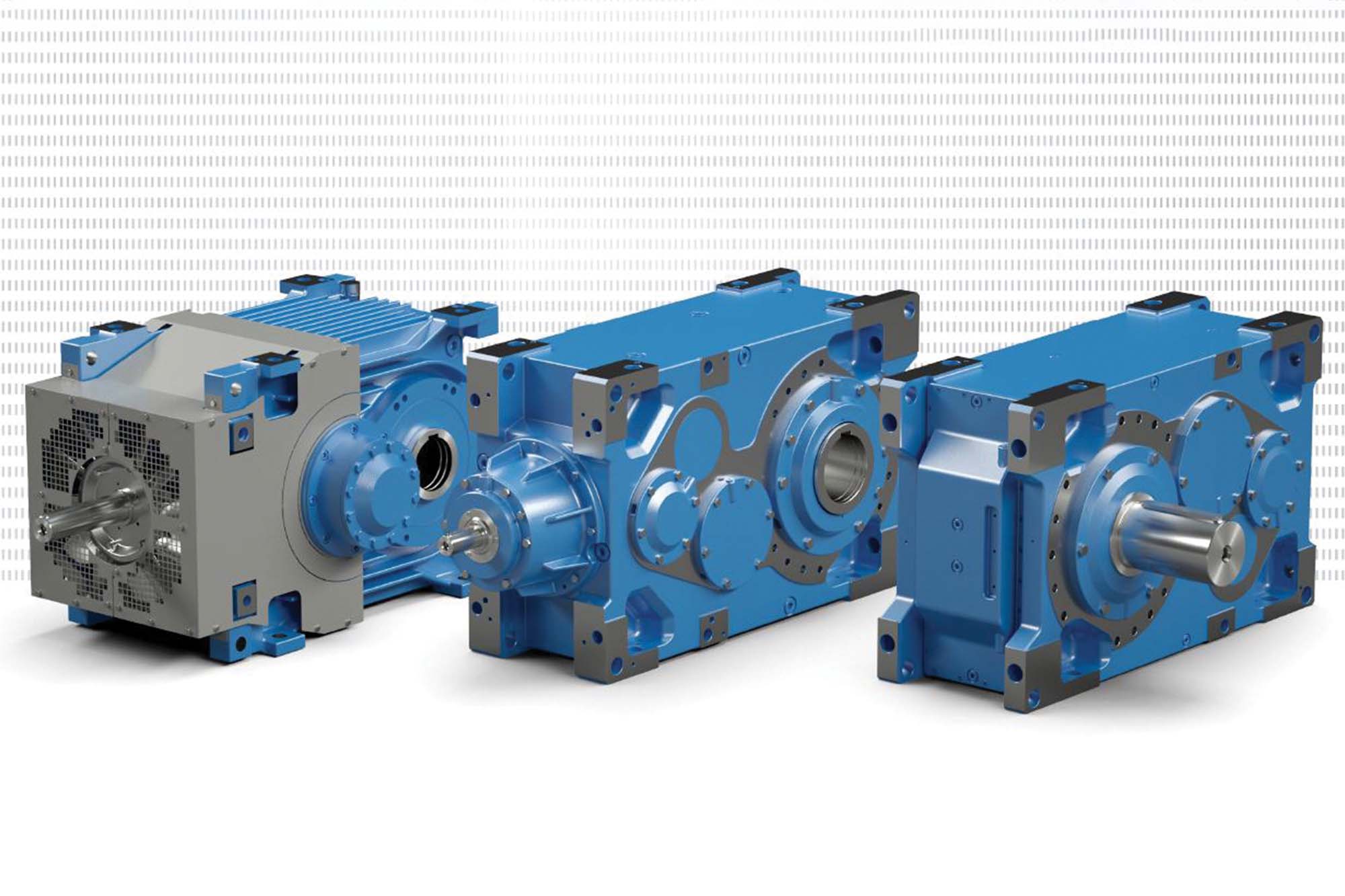

We are focusing on creating more compact gear units without compromising performance. Our NORDBLOC.1 helical inline and bevel gear units provide high power density and are suitable for applications with limited space. They are lighter and compact while maintaining high torque and reliability.

Our modular design makes configuration flexible. Users can select the ideal gear unit, motor, and drive electronics combination for their specific needs. The efficient and compact drive solutions are tailored to different industries, such as intralogistics and food production.

Decentralised Drive Systems by NORD has decentralised drive technology with integrated frequency inverters, such as the NORDAC FLEX and NORDAC LINK. These systems are installed directly on the machine, eliminating the need for control cabinets and reducing wiring complexity, making them ideal for compact installations.

We are integrating intelligent systems that monitor and optimise gear performance. This includes predictive maintenance features to ensure the system runs smoothly without interruptions. This improves efficiency while extending the system’s lifespan, reducing downtime and maintenance costs.NORD uses advanced materials that reduce wear and improve gears’ durability. Our UNICASE housing design, for example, minimises material use while bringing stability and longevity.

What role do smart motors play in predictive maintenance within automated manufacturing environments?

Smart motors integrate advanced sensors, connectivity, and data analytics into the motor system. This combination allows for real-time monitoring and predictive analysis of motor performance. We can detect the potential issues before they lead to failures. Smart motors enable condition-based maintenance, which thus helps reduce unplanned downtime instead of relying on time-based maintenance schedules. Smart motors are integrated with Industrial Internet of Things (IIoT) platforms, enabling remote monitoring and centralised control. We offer products that are Industry 4.0 and predictive maintenance ready.

Can you explain the impact of gear design improvements on reducing power losses in transmission systems?

NORD Drivesystems designs geared motors in UNICASE design for housing and with a double lip oil sealing system. We use the highest manufacturing standard, like DIN 3990, which ensures high comprehension efficiency. Also, our design provides long maintenance intervals & oil changes, i.e. 18 months/ 10000 service hours or 36 months/ 20000 service hours, including 1st change.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.