Intelligent monitoring

By OEM Update Editorial June 29, 2017 11:58 am IST

Simple way of making our workplace more appealing is by embracing digitisation and ensuring we are getting the most from it.

Micro System Engineers, a part of AGDP Ventures, design and develop innovative solutions for smart factories. Atul Garg, Group Head (Business Development) of the company explains why digitisation is at the centre of discussion today.

Adopt digitisation all across

Digitisation plays a vital role in the manufacturing process and should be adopted by entire manufacturing industry. It helps keeping a track of manufacturing process and quality of product being manufactured. Each important parameter of process will be recorded to ensure quality and quantity tracking. Also, flaws if any with respect to process or product, can be rectified by post analysis of recorded data.

Moreover, digitisation makes it possible to monitor and evaluate the process by senior officers and experts to take corrective actions if required. This monitoring can be performed by process parameters or information being available vide internet over secure cloud.

Digitised manufacturing process also helps in effective predictive maintenance, wherein appropriate on-line sensors were installed to get prior information about expected fault to ensure ‘no breakdown’ to best possible level.

Indian manufacturing sector is all prepared

Indian manufacturing sector is all set and prepared to move over from traditional methods to digital method for upgradation. Globally, manufacturing segment had experienced considerable increase in revenue by opting digitised manufacturing process like implementing IoT (Internet of Things). Not only can the digitisation of manufacturing provide manufacturers with better internal processes and enable greater efficiency and thereby improved profitability, but it can also enable them to attract more quality employees who love to be updated. But for small scale industries, it heavily depends on preview of the promoters in terms of the cost involved with respect to returns.

Smart solutions with smart features

Micro System Engineers, being a Research & Design organisation, is intensely involved in developing solutions which are fully automated and hardly requires manual intervention. Manual actions are involved to take corrective action once our solution highlights the flaw or problem in manufacturing process.

Micro System Engineers has designed and installed lots of solutions for smart factories. Some of the highlights are:

Coal Pile Thermal Monitoring (CPTM): To avoid coal fire. This is on-line thermal imaging camera based solution to detect any hot spot in coal yards due to spontaneous combustion. This hot spot will be highlighted along with location detail in the control room i.e. an alert is extended much before it becomes a fire. Alert will be extended visually or audible and send as an SMS/ E-mail instantly prior to smoke or red hot spot being visualised by naked eye.

Water sprinklers will be activated automatically for hot spot zone only in case no action has been initiated by designated staff to control combustion.

Inspired by ‘Make in India’ program launched by Prime Minister Narendra Modi, Micro System Engineers has designed and developed this solution within the organisation although thermal camera used is manufactured by Flir Systems, Sweden.

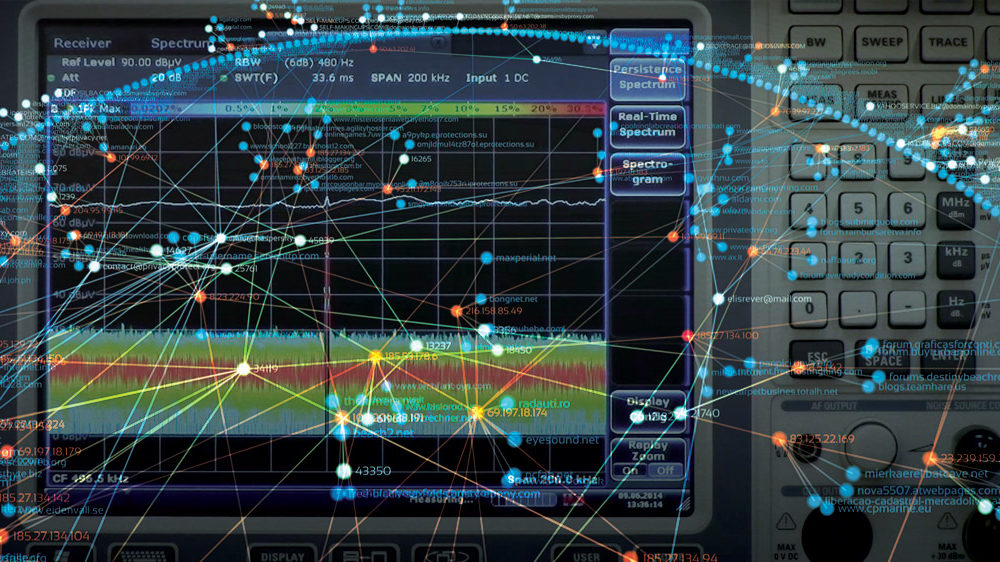

Grid Thermal Remote Monitoring (GTRM): To avoid breakdown in electrical grid and sub-stations. This is another on-line thermal camera based solution to detect hot spot in electrical sub-stations. This is a given fact that any substation breakdown will be followed by increase in temperature for that particular region. Breakdown only occurs if no action is taken on time. GTRM ensures detecting hot spot much before it leads to breakdown. Concern officers get enough time to take preventive action so that sudden breakdown can be avoided.

This solution includes lots of smart features like on-line continuous monitoring of entire grid by thermal camera being installed over a ‘Pan & Tilt’ mechanism to cover maximum area with single camera. Designated officer can access the substation for manual control and monitoring wide web cloud. Since complete substation is monitored 24×7 automatically, fire accidents can also be nullified.

OHE Line Thermal Monitoring

Thermal Imaging based solution to detect any abnormal hot spot in OHE lines (25 kV) which use to feed power to trains. This solution uses a thermal camera to be installed over train roof and look out for any hot spot which can lead to breakdown of train supply. Complete scanning is done automatically with manual intervention. At the end of journey, user will get a sheet stating problem area with GPS location to be attended for smooth functionality.

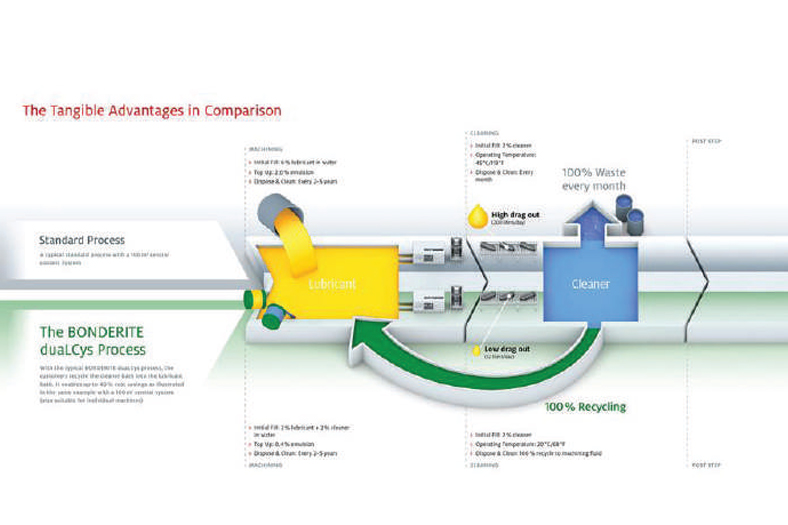

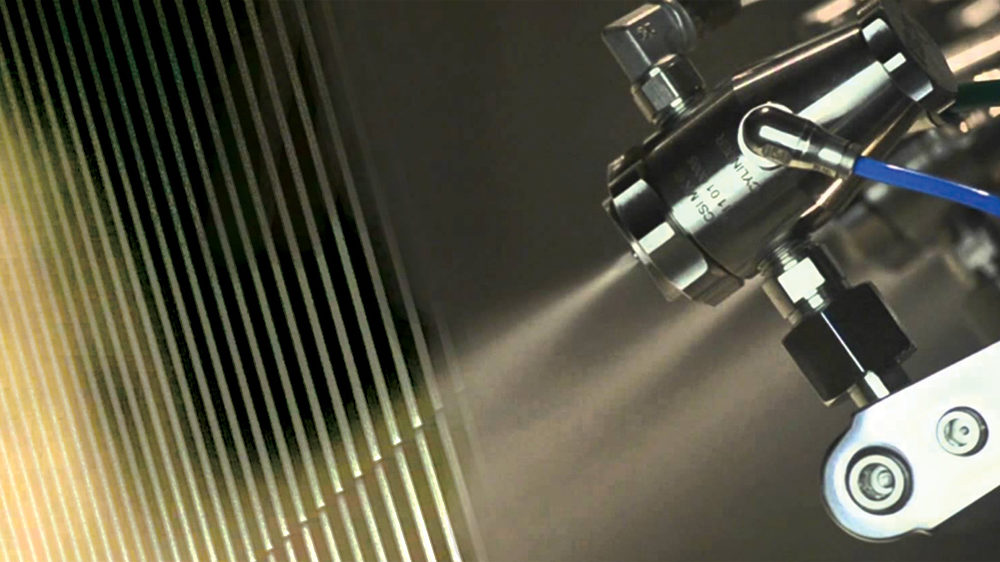

Efficiency enhancement solution: Under technological collaboration with Innotech, Germany Micro System Engineers has introduced Smart Efficiency Enhancement program for air cooled heat exchangers. This service ensures fetching maximum possible efficiency from the heat exchangers and hence considerable increase in revenue. The service provided under this program is completely digital and uses controlled

water jet pressure as per requirement. This also ensures using least possible water and this water can also be recycled.

Digitisation for control and monitoring

Micro System Engineers embraces digitisation by implementing as much features as possible using software coding or application in the solution they design. The company’s solutions ensure proper control and monitoring of manufacturing process with IoT and various other smart methods. Solutions designed by them give flexibility to user to get an access of the process on-line over web cloud for control and monitoring.

Micro System Engineers believes that, simple way of making workplace more appealing is by embracing digitisation and ensuring getting the most from it.

The company aims to design solution which requires least possible human action or monitoring. Manual intervention will be required to compliment the solution by taking timely action as per resultant of solution in order to get desired results.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.