Boost productivity with anti-sloshing

By OEM Update Editorial July 17, 2017 12:16 pm IST

Transport liquids faster without spills

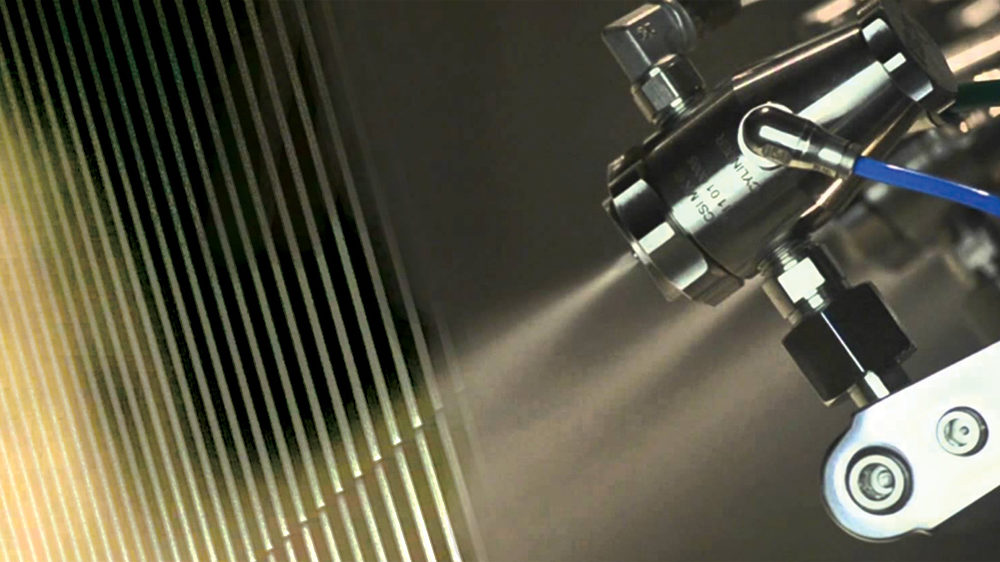

With B&R’s industrial transport system, it is now possible to transport liquids quickly with no spills. SuperTrak is the only system on the market to offer anti-sloshing technology. This technology suppresses the formation of oscillations on free surfaces to prevent liquids from spilling over container edges during transport.

No spills from open containers

The term slosh is used to describe the behaviour of liquids in moving containers. Specially designed movement profiles prevent the development of positive feedback loops on the surface of the liquid so that it remains calm during transport. This minimises downtime and increases productivity when handling open containers.

Minimising oscillations on the surface of liquids is particularly important in the packaging industry. The better you are able to control sloshing, the faster the products can be transported. B&R’s sophisticated anti-sloshing technology also prevents the formation of air bubbles and foam. The downtime otherwise required to allow the liquid to settle is reduced drastically or eliminated entirely for a substantial improvement in packaging line productivity.

As the only system on the market, SuperTrak offers anti-sloshing technology that suppresses the formation of surface oscillations to prevent liquids from spilling during transport.

For more information, visit www.br-automation.com.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.