Best practise to prepare metal surface for coatings

By OEM Update Editorial July 14, 2018 10:44 am IST

Highlighting the best ways to clean and prepare metal surface for coatings

The surface finish before coating is an important part of the painting process, with a big impact on coating life, coating appearance, dry film thickness and paint use. Studies have shown that more than two thirds of all coating failures are attributed to poor surface preparation that could have been prevented. Here, we highlight the best practices to get a clean and finished metal surface.

Latter – A highly effective method

Lokesh Saxena, Managing Director, DISA India Ltd, says, “Surface preparation methods range from manual cleaning with wire brushes or power tools to chemical cleaning and shot blasting. The latter is a highly effective method, removing contaminants from the surface consistently across an area and creating a defined surface profile of even peaks and troughs – ideal for coating adherence.”

He adds, “The result is a cleaner, more even finish and a precise anchor profile for coating. The better the anchor profile, the better the coating and the more even and precise the peaks and troughs; the less paint is needed to achieve the same coating coverage.”

Increasingly, blast clean finishes are specified by paint manufacturers or prescribed by standards, even for applications where good coating was long considered unnecessary.

Crushed glass – Latest innovative product

According to Praveena Jolly, Business Development Associate, Blastline India Pvt Ltd, “There are various factors to take into consideration when choosing your abrasive for surface preparation. If the objective is to clean and prepare metal surface, the most efficient and economical way is to use crushed glass abrasive. Crushed glass is the latest innovative product to enter the abrasive sector and arguably the best one yet. The advantages and benefits of crushed glass is multi-faceted and trumps all the other abrasives currently available in the market.

Crushed glass grit is made from 100 per cent recycled glass and contains no heavy metal or silica; so, it conforms to the present market’s inclination to being green and environmentally friendly. It has an angular shape and a Mohs hardness of 6.0. It needs only to be blasted at 90 psi to achieve optimal results and its unique properties give off translucent dust when blasted, which means the operator’s improved visibility of the surface can significantly improve productivity and efficiency.”

Jolly claims that Blastline India, is the leading supplier for the surface preparation industry and they are the first to introduce this abrasive to the Indian market.

Different parameters and media mix

Pratik Sikka, Head of Marketing, Accumech Solutions, opines, “The optimum solution may vary for different problems, but the mechanical method through high-pressure blasting or propelling the media on to the surface of the substrate is generally the most effective, efficient and economical solution.”

He adds, “There could further be different ways of doing so : Air-assisted or air-less depending upon the size, shape, weight, production demand, type, composition and required results. Then there is a variety of abrasives for different constraints in quality, texture, chemical compositions, etc.”

So, an optimum solution to almost every problem related to surface preparation can be figured out through managing the different parameters and media mix; hence, this method out stands all the other methods.

Latest surface blasting equipment for metal surface

Roller conveyor shot blast machineSaxena from DISA says, “For steel, the RB series roller conveyor shot blast machine is the proven solution for the descaling of plates, sections, profiles, fabricated jobs and more.”

Saxena adds, “Our preservation lines combine the heating (drying), blasting, coating and drying of work pieces such as sheet steel, profiles, pipes or steel structures in one automatic line. Preservation lines are ideal when there is a lengthy manufacturing or storage time between blasting and final coating. In order to prevent rust returning, a weld primer is applied to provide corrosion resistance for weeks.”

For steel wire and rod applications, DISA has the FL series shot blast machine. Both these offerings are technology transfer products from its centres for product innovation in Germany and Switzerland. The first indigenised RB-I 2500G is in final testing at company’s plant in Hosakote.

For aluminium, a lot of different machines types (LBS, SPH, DHB, HB, robot gripper, etc.) are available; suitable for a wide range of aluminium parts. DISA help sits customers find the best solution – depending on their specific application (improving the aesthetics of parts, preparing surfaces before coating) and taking into account factory layout requirements, for example, the cell concept is common in aluminium foundries.

For castings, DISA’s latest inline cleaning machine concept is the IBC (Inclined Belt Conveyor) shot blast machine for the descaling or cleaning of, for example, ventilated brake discs. This is now available directly from there Indian operations. Also, Wheelabrator offers a complete range of shot-blast solutions.

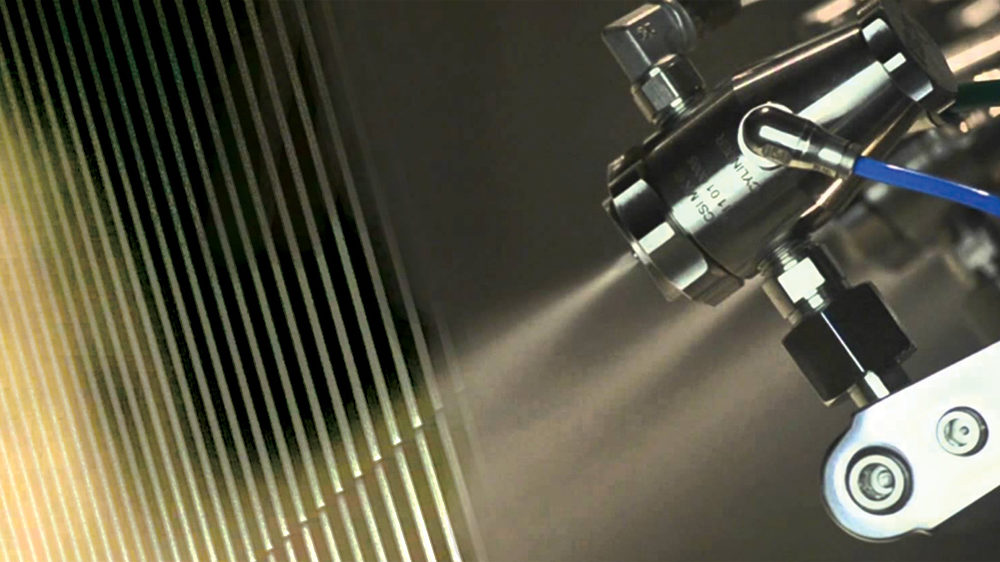

Graco’s EcoQuip 2

Jolly from Blastline informs, “Graco’s EcoQuip 2, the newest technology in vapor abrasive blasting which precisely injects moist abrasive into the blast stream that can suppress dust levels up to 92 per cent. This is not to be confused with slurry blasting, which is blasting with slurry of air, water and abrasives that ends up wasting too much water and abrasive and creating a significant pool of contaminated water that is difficult to contain and dispose of. Vapor blasting instead only uses minimal water (usually around 0.5 to 1.0 qt/min), which can lead to significant savings in abrasive and water consumption.”

Another exceptional trait is that of MediaTrak, the equipment’s precise media consumption monitoring feature. This feature allows one to not only track, but also control and change the media consumption based on the job at hand. Blastline India is the authorised distributor for Graco’s high pressure airless painting machine and the aforementioned EcoQuip 2 in India.

Dustless portable blaster

Accumech’s latest offering is a product by the name of dustless portable blaster which is air-assisted blasting equipment suitable to variety of media (glass beads to sand with water). Sikkafrom Accumech says, “Our product empowers our clients to operate effectively in an eco-friendly manner; the operation of machine is very handy

and the power consumption is lower than the other substitutes.”

For steel, the RB series roller conveyor shot blast machine is the proven solution for the descaling of plates, sections, profiles, fabricated jobs and more.

Lokesh Saxena, Managing Director, DISA India Ltd

Graco’s EcoQuip 2, the newest technology in vapor abrasive blasting which precisely injects moist abrasive into the blast stream that can suppress dust levels up to 92 per cent.

Praveena Jolly, Business Development Associate, Blastline India Pvt Ltd

Our product empowers our clients to operate effectively in an eco-friendly manner, the operation of machine is very handy and the power consumption is lower than the other substitutes.

Pratik Sikka, Head Of Marketing, Accumech Solutions

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.