Behind the facade of counterfeit consumables

By admin November 28, 2015 11:17 am IST

What manufacturers need to know when purchasing plasma torch consumables

Ask any original equipment manufacturer (OEM) to share their critical business challenges, and they are likely to raise common issues such as quality control, efficiency levels, budgeting, and inventory management. However, with the advent of technology and globalisation, modern OEMs are now faced with yet another area of concern – the proliferation of counterfeit products.

Counterfeiting has evolved over the years, from being largely localised operations into highly profitable global businesses with mass production facilities, international sales, and complex global distribution networks. According to the International Chamber of Commerce (ICC), the value of global counterfeit goods is expected to exceed $ 1.7 trillion by 2015.

In the past, counterfeiting used to be more prevalent in consumer goods, but counterfeiters have started to target highly sophisticated and engineered products in recent years, and B2B companies are similarly at risk to product piracy. One such example is in the consumables of plasma cutting systems, such as nozzles, electrodes, and swirl rings.

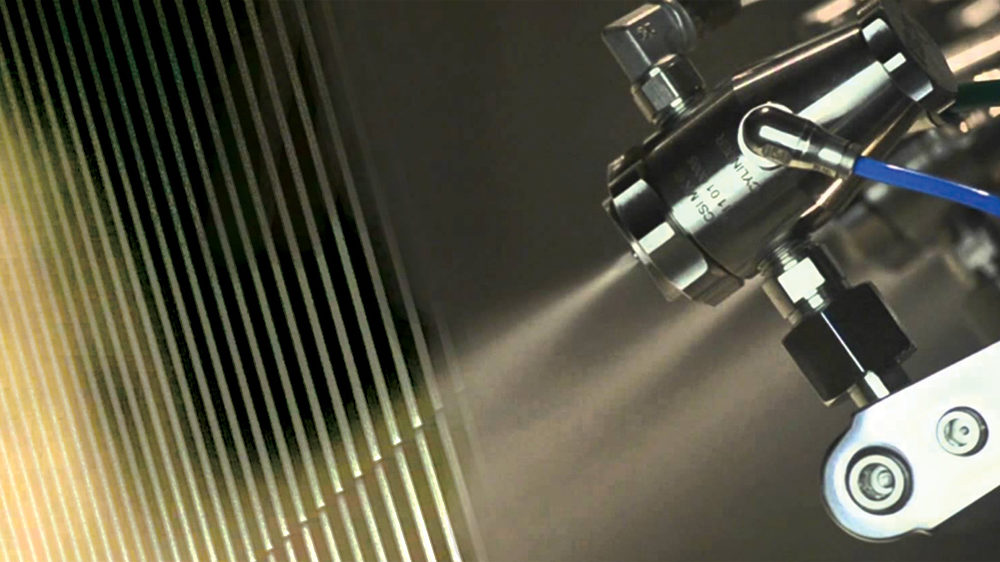

Counterfeiting in plasma cutting consumablesPlasma cutting makes use of an electrically conductive gas, such as nitrogen and oxygen, to cut through conductive materials. A typical plasma cutting system consists of the power supply, an arc starting circuit, and a torch. The torch serves as the holder for the consumable nozzle and electrode, and provides cooling (either gas or liquid coolant) to the consumables, while the nozzle and electrode constrict and maintain the plasma arc.

Today’s high precision plasma cutting systems are capable of producing cut parts of higher quality at faster speeds, with little or no post-production processes. Yet, a plasma system is only as good as the consumable parts in the torch. Even with the latest advances in technology and torch design, a high performance plasma system can become mediocre when inferior consumables are used.

So what constitutes a counterfeit? Counterfeits are products made in exact imitation of something valuable or important, with the intention to deceive or defraud a customer into thinking that the product is an original. There are various reasons as to why an end user would unknowingly purchase counterfeit consumables. More often than not, the relatively lower price is what attracts them, as counterfeit consumables are known to sell for minimally 30 percent lesser than the original. As counterfeits are usually close copies of the genuine product in appearance, at times, end-users may actually be unaware of their counterfeit purchase, and are misled to think that they are getting a good bargain instead. Why go original?Unlike the OEMs, most customers are probably unaware of the dangers and consequences of using counterfeit consumables. It may also be a challenge for them to identify the counterfeits. Poor equipment performance that is directly due to the counterfeit consumable is mistakenly attributed to the product’s brand instead. In turn, this creates the false impression that the original equipment is unreliable, which negatively impacts the company’s branding, credibility, and reputation.

Here, five reasons are highlighted why the use of counterfeit consumables can be more counterproductive than beneficial.

QualityNon-genuine consumables are manufactured only with quick profit in mind. Often times, they are manufactured with techniques that focus primarily on rapid mass production instead of quality. Counterfeit suppliers lack the stringent manufacturing processes found in original products, and they simply replicate the parts used in the most popular manufacturing equipment with no proper quality control and checks. They also tend to use the lowest cost materials that are more prone to wear and tear. As a result, the copies may look the same but they lack the quality and durability that original consumables offer, often resulting in poor cutting capabilities. In most cases, the performance of the counterfeit consumable is inconsistent and unreliable, which significantly increases downtime. Actual photographs of the manufacturing facility of an OEM (Hypertherm). In comparison, the factory is well organised with clearly segmented work areas, and well-maintained equipment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.