Advanced CNC solution for precision milling machines

By OEM Update Editorial October 26, 2016 9:33 am IST

Fully scalable control system suits wide range of precision milling applications

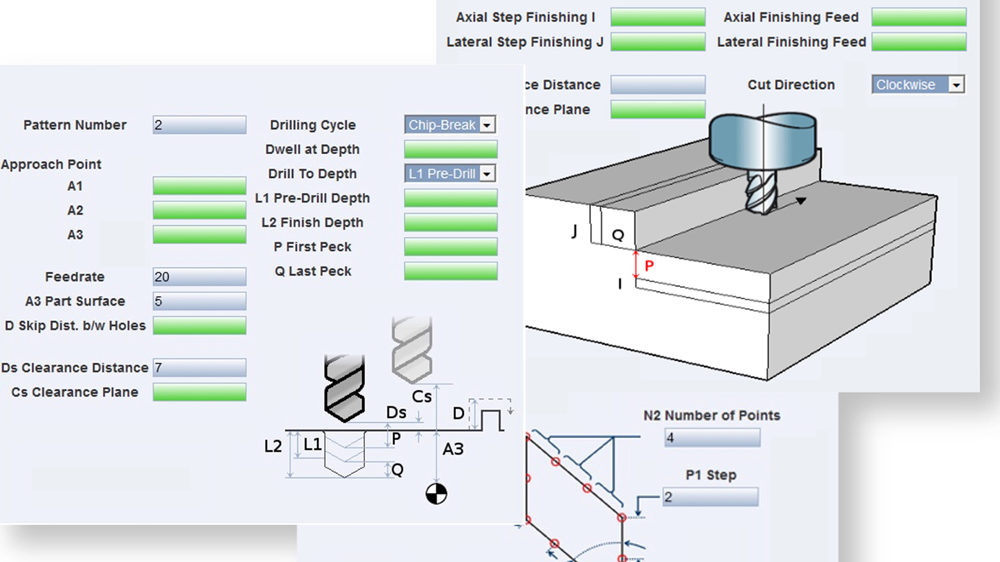

NUM has launched an advanced control solution for CNC milling machines that features a highly intuitive conversational style user interface. Known as NUMmill, the CNC hardware and software provides a fully scalable control system and is supplied as a complete ‘off-the-shelf’ package.

NUMmill is designed specifically for CNC milling machine manufacturers and control retrofitters. It offers an extensive suite of canned cycles, ranging from simple centre drilling, boring and threading to pocket cycles and complex profile milling cycles. All with 3D simulation for pre-process verification. The package is suitable for a wide range of precision milling applications in markets as diverse as metal cutting, woodworking, plastic, and high precision machining.

Based on NUM’s market-leading Flexium+ modular CNC platform, NUMmill is typically configured with 3 or 4 linear axes and a single rotary axis, though it easily scales to suit any size and type of milling machine application. All motorised axes are equipped with high performance brushless servo motors, controlled by NUM’s latest-generation NUMDrive X digital servo drives. The NUMmill software features an exceptionally easy to understand graphical user interface which employs an interactive, conversational style dialogue to radically simplify machine operation. In fact, it is so simple to use that end-users can operate machines without any prior knowledge of ISO code programming techniques.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.