The grail of energy

By OEM Update Editorial November 13, 2018 4:25 pm IST

Increased energy efficiency and safety compliance are hightly significant for industry. Here is special report on how to define optimal sizing of energy storage systems for industrial use.

Industries cater to about 45 per cent of the power consumption in India. Having a well-planned energy system not only brings resilience, but also significant cost savings. Due to various environmental and sustainability parameters, focus is on deployment of renewable energy sources and reducing the use of fossil fuels as much as possible.

Defining the optimal sizing of energy storage systems for industrial use

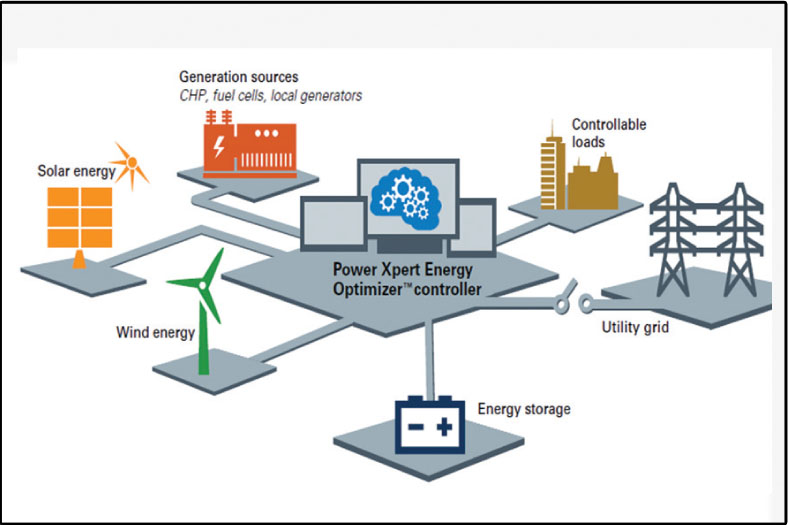

The initial investment on energy storage is a bigger constraint. It becomes important to size the storage optimally to have maximum utilisation and minimum expense. Based on the load profile of the user, peak shaving can be planned by load levelling. Demand response can be planned based on the hourly active power requirement. The independently operating system of generators can be transformed into a demand managed micro grid. The use of lithium ion batteries, flywheels and ultacapacitors for storing energy has been popular among users. Each technology has its own application benefits and constraints. Eaton’s microgrid installation at US Base Military is a testimony of its expertise in the field. The design seamlessly integrates various components with the use of Power Xpert Energy Optimiser Controller for optimal source dispatching and demand control.

Industries should plan system audit and design for increased energy efficiency and safety compliance. Experts from Eaton can help keeping your next project on time and on budget.

Significance of power quality monitoring system in the aspect of industrial operations

Power quality affects many aspects of industrial operations. Poor power quality means loss of production and man-hours, manufacturing interruptions, and decline in productivity because of equipment failure and decreased machinery lifetime. This can largely affect the revenue of the industry. Having a strong power monitoring system can help industries overcome this challenge. Deployment of uninterruptible power supply systems to provide clean power to the machineries is a recommended solution to the problem. While most UPSs available in the industry provide basic level power conditioning, Eaton UPS systems are specially designed to meet the most stringent challenges for industrial environment.

Back feed protection: It refers to a situation when power is fed back to the input terminals of an electrical device, which can result in serious disturbances at the common coupling point. Back feed protection in the UPS device shields the bypass line from static switch failure. The internal back feed contactor is used to automatically protect against fault situations within the static switch.

Hot sync technology: When more than one UPS systems are connected in parallel and they are powered from different sources (input and bypass), chances are, it may fall out of synchronisation because of input power disruption. This will in turn affect the connected load. Competitive UPS products in the market utilise centralised or distributed load-sharing technology with the master-slave principle, which introduces a risk of single point failure. The absolute reliability of a UPS system can be achieved with Hot Sync technology. The secret here is a patented built-in digital signal processor (DSP) algorithm, running continuously in each unit. It drives the UPS outputs toward synchronisation and takes care of load sharing. If there is a common bypass available, it is used as valid synchronisation source for output. In the absence of a common bypass, the processor makes subtle adjustments to the inverter frequency on the basis of output power level measurement in order to find a common frequency and load balance among the units.

Apart from the above mentioned features, Eaton UPS systems are capable of operating in wide power factor range, which makes it capable of feeding the loads without de-rating, and your processes will not be affected.

Authored article by:

Pallavi Sinha

Prescription Manager –

Electrical Sector

Eaton Power Quality Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.