Industry 4.0: Yet to be merged with welding

By OEM Update Editorial June 18, 2019 11:15 am IST

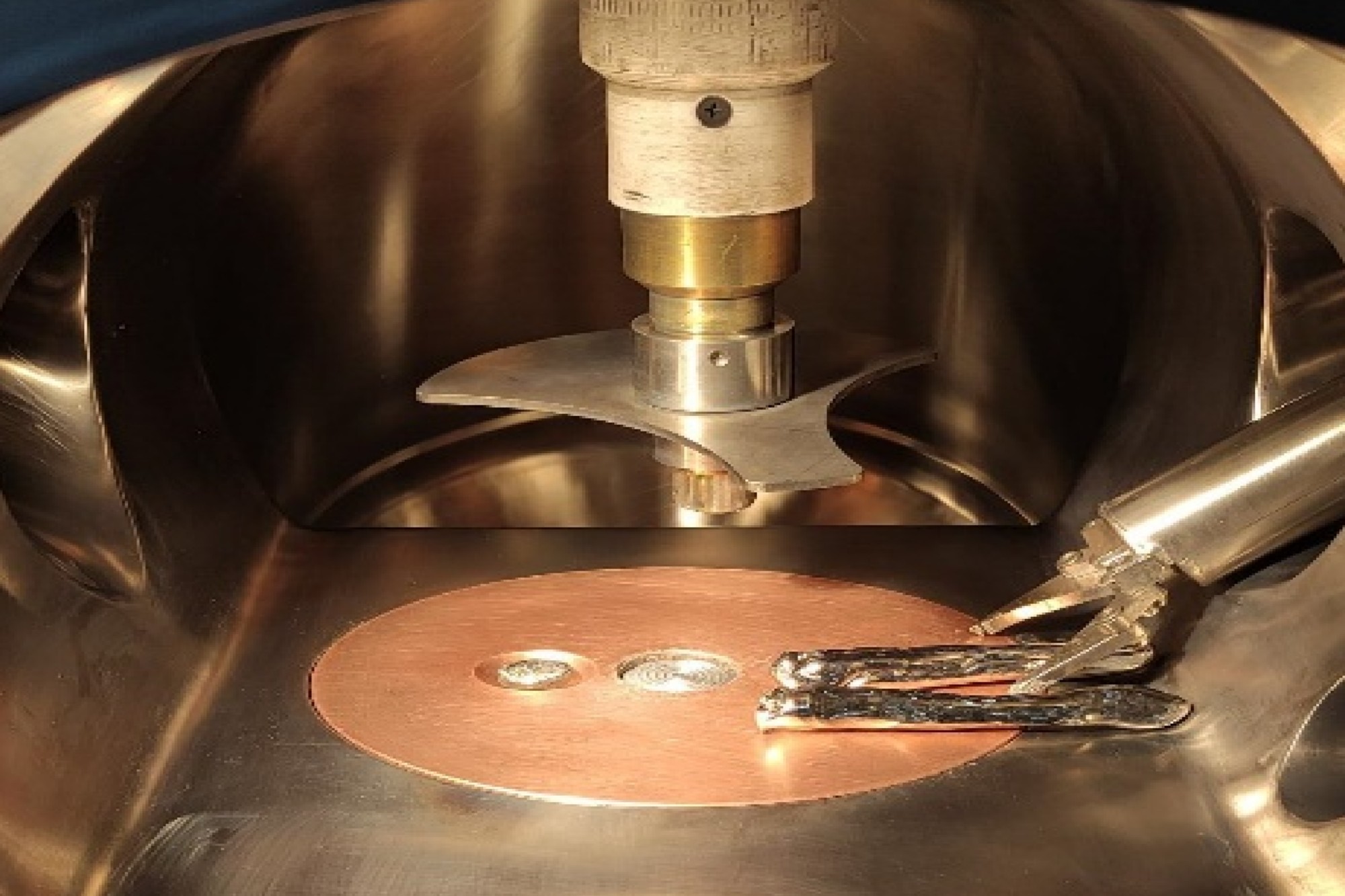

Vishwanath Kamath, Managing Director, Fronius India Pvt. Ltd. discusses on how welding is an integral part of process and manufacturing.Without welding, there is no manufacturing or growth and no growth means there will be no GDP growth or economic growth.

Make in India for India’s welding industry

Make in India and manufacturing, is really a new dawn for a new India, because I could see that many products, which have been earlier manufactured in Europe, because of this initiative, are now forced to manufacture in India. This is really helping the welding industry because welding is the backbone of any manufacturing industry. So, the more you make in India, it’s better for the welding industry.

Digital India for welding industry

When it comes to welding, people are not able to relate IT and welding, especially the manufacturing sector. But because of the implementation of Industry 4.0, people now know the advantage of IT and they want to have information in their fingertips.

However, it will take some time for Industry 4.0 to merge with welding. However, Fronius has all the equipment Industry 4.0 ready. Unlock the licence and you can have all the welding data on a connected network. However, this awareness is, as of today, at a manufacturing level, is very minimal and any upgradation will take some time. Government is taking effort; there are so many conferences happening on Industry 4.0 or IoT in manufacturing sector, but at the end of the day everything boils down to cost and Indian manufacturing industry should invest more.

Welding being perceived as a blue collar job

There was an accident in Mumbai a few months back, where a railway bridge collapsed; one of the reasons was welding failure. So, it’s exactly right to say that welding is the key element between success and failure of a product. It’s a product which saves human lives.

The welding fraternity has to play a big role, with the government to boost welding industry. Today what’s happening is that the curriculum of the government sector talks about the oldest style of the welding; irrespective of the fact that many things have been upgraded. At one side, you are talking about Digital India, where you want people to operate everything digitally and other side, you are teaching the old school method of welding. This doesn’t go hand in hand. Welding industry definitely requires a lot of working.

Welding courses, need of the hour

Apart from government, what is more important is that all technical education institutes need to paint welding not just as a blue collar job but a high paying one, which is worth pursuing. We need to bring welding at the forefront. We, on an estimate, have a shortage of 20,000 welders every year. So, if you’re talking about growing at a rate of 8 to 10 per cent GDP, then you require even many more welders. So to bring about this, I think the government and the private colleges need to bring in some incentivising welding courses. For example, no college in India offers B.Tech specialising in welding. We say welding is an integral process of manufacturing but there is no course which offers a welding technology as a bachelor degree.

The future?

The Indian welding industry is in a good shape. Last year, it was fantastic for all the welding industry. As long as economy grows, manufacturing grows, welding will definitely grow. Indian customers have now become smart because they rely more on quality products. For Indian and other manufacturers, the industry would prove to be very robust; but, unless we don’t address the key issue like required skillset, people won’t get attracted to welding industry. We need to showcase the right picture about welding as a bright career.

Also, whenever you do a welding show, the manufacturing industry hardly visits a welding show. This is also one of the major concerns. For that, we definitely require government support in pushing their R&D units to make them visit the welding shows, so that they also come to know what’s happening in the welding industry. It can be a win-win situation for an economy as well as welding industries.

At one side, you are talking about Digital India, where you want people to operate everything digitally and other side you opt for the old school of welding methodologies; this doesn’t go hand in hand

Vishwanath Kamath, Managing Director, Fronius India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.