Cleanliness is more than biocompatibility

By OEM Update Editorial April 11, 2018 5:23 pm IST

In the medical engineering world, the concept of cleanliness is primarily associated with microbiological contaminations. In order to protect both operatives and patients there has been a growing emphasis in recent years on the removal of residues left by the manufacturing or assembly process, whether in the form of particulates or chemical films. This calls for cleaning solutions that are consistently reliable, and at the same time cost-effective.

In the case of microbiological contaminations, or so-called bioburdens, the manufacturers of medical engineering products such as implants, medical instruments and operating instruments for traditional and minimally invasive surgery are able to refer to a whole raft of norms, standards, regulations and procedural instructions which tell them how to deal with different types and quantities of contaminants. But it is a very different story when it comes to other organic and inorganic substances such as the residues of processing media or processing aids, release agents and chemical surfactants, particles, fibres and dust. Hitherto these have been covered by only a handful of norms and regulations, such as ISO 8536-4. But these substances – even if they have been sterilised along with the medical engineering product itself – can still pose a risk inside the body of a patient; so the need for effective cleaning has now become a growing concern. This means, on the one hand, achieving high standards of cleanliness and biocompatibility, while on the other hand it is necessary to ensure that the surface and other characteristics of the product are not modified or altered by

the cleaning process itself. Proper validation of the cleaning process poses a further challenge for manufacturers.

Factors governing the choice of the cleaning process

Various technologies are available for cleaning, including wet chemical cleaning processes, CO2 blast cleaning and plasma cleaning. Key factors governing the appropriate choice of process include the material or combination of materials involved, component size and geometry, the type and degree of contamination, throughput rate, required flexibility, the cleanliness specification with respect to particulate residues and surface films, and the production stage. A number of other aspects also need to be considered: At which points in the production operation are the parts contaminated, and with what? Do the contaminants need to be removed immediately, typically because they would jeopardise the next processing stage? Are the processing operations carried out with different agents or aids which could make cleaning problematic if they are intermixed? Is there a risk of cross-contamination if parts made from different materials, such as titanium, stainless steel, tungsten carbide and ceramics, are treated in the same cleaning plant?

The optimum cleaning solution, both technically and commercially, quite often consists of a combination of different procedures.

Wet chemical cleaning – standard procedure in the medical engineering sector

With metal or plastic parts, the required results in the majority of cleaning applications in medical engineering can be obtained by using wet chemical processes.

When choosing a suitable cleaning agent, the chemical principle “like dissolves like” is a useful guide: aqueous cleaning agents are generally used to deal with water-based (polar) contaminants such as polishing pastes, salts, dust and grit, and other solids. It is advisable to carry out tests to establish that the materials are compatible and the end results satisfactory. It is also important to check that the cleaning agent is a suitable match for the particular type of process being used, such as spraying or ultrasound; failure to do so can lead to unwanted consequences such as foaming. In order to ensure the required biocompatibility when cleaning with aqueous agents, it is usual to carry out final cleaning in several stages. This is normally done, at least at the final rinsing stage, using fully desalinated water. This ensures that no cleaning agent residues or water stains are left on the surfaces which would impair the quality and biocompatibility of the components.

Mechanical action optimises the cleaning effectThe effect of the cleaning medium is enhanced by a number of physical processes of varying intensity such as spraying, immersion, ultrasound and pressure flushing. The technique most often used in medical engineering applications is ultrasound. A relatively new wet chemical process that has so far been used in the semiconductor industry, some specialised areas of medical technology and in the optical industry is cyclical nucleation (CNp). Like ultrasound cleaning, it is based on the physical effect known as cavitation, which is here combined with an asymmetric volume flow rate. This combination makes it possible to dislodge particulate and film-like contaminants even from very fine capillaries, borings and 3D structures with consistently dependable results, and without damaging the substrate material. Cleaning is carried out in a closed chamber filled with cleaning agent, which is placed under vacuum. This causes millions of tiny gas bubbles to form in the liquid, which are then deposited on all the surfaces of the workpiece – even inside capillaries, borings and complex 3D structures. The vacuum is then released, causing the bubbles to implode. This cycle produces short, powerful pulses that have a strong mechanical effect on the component surfaces, effectively dislodging any contaminants attached to them. The critical cleaning effect results from the definition of a fixed cycle between the upper and lower switching point in the vacuum. This can be repeated and varied at will – hence the name “cyclical nucleation”. The pressure amplitudes cause the tiny gas bubbles to form and implode in an endless cycle. Cyclical nucleation can be used on its own, or in combination with traditional wet chemical cleaning processes.

Special processes for special applications

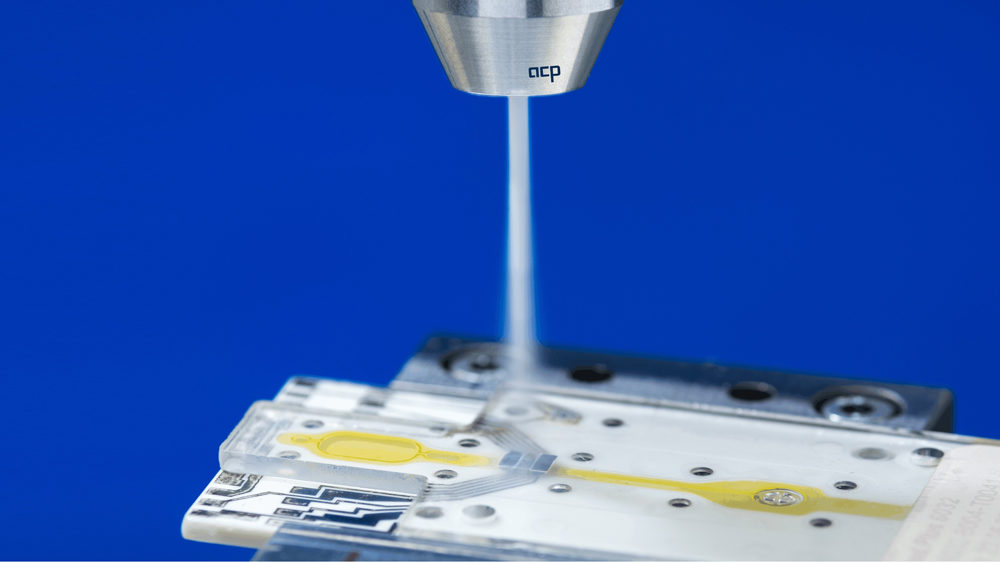

For special applications in the medical engineering sector, processes such as CO2 and plasma cleaning have been found to be effective. CO2 cleaning is typically used for the final cleaning of metal and plastic endoscope components, the micro-deburring and ultra-fine cleaning of one-way systems made of plastic, such as lab-on-a-chip products, and also for combined lubrication, cooling and cleaning during the machining of implants and medical engineering components made from PEEK.

Biocompatible plasma is typically used in medical engineering for the fine cleaning of stents, surgical and dental implants, and guidewires prior to coating with hydrogel or PTFE, and for increasing surface energy in microtiter plates.

Solutions for the verification of cleanliness

Norms and standards for the verification of residual particulate contaminations in the medical engineering field are virtually non-existent, apart from a few that relate to specific products or product groups. And the verification procedure is often described in vague terms, making it effectively impossible to compare different results. The standard reference work used in the automobile industry, known as VDA 19 or ISO 16232, offers some useful guidance on testing for residual particulate contaminations that can be applied to medical engineering products. A number of test laboratories that specialise in industrial cleanliness already offer services that are applicable in the medical engineering field.

Residual contaminations in the form of chemical films can be identified and quantified on components of any geometry with the aid of a measurement process based on vacuum-induced desorption. In this procedure, the quantity of residual contamination on the surface of the component is determined in grams, so that appropriate threshold values can also be defined. Furthermore, contaminants can be clearly identified, along with their source – for example, residues left by manufacturing aids.

Author:

Doris Schulz

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.