Advanced wire feeding welding techniques

By OEM Update Editorial November 13, 2018 4:00 pm IST

Ador Welding Ltd. one of the complete welding solutions provider with manufacturing plants located across the country provide welding consumables and equipment, welding automation solutions, CNC cutting systems, PPE & Gas cutting products and accessories.

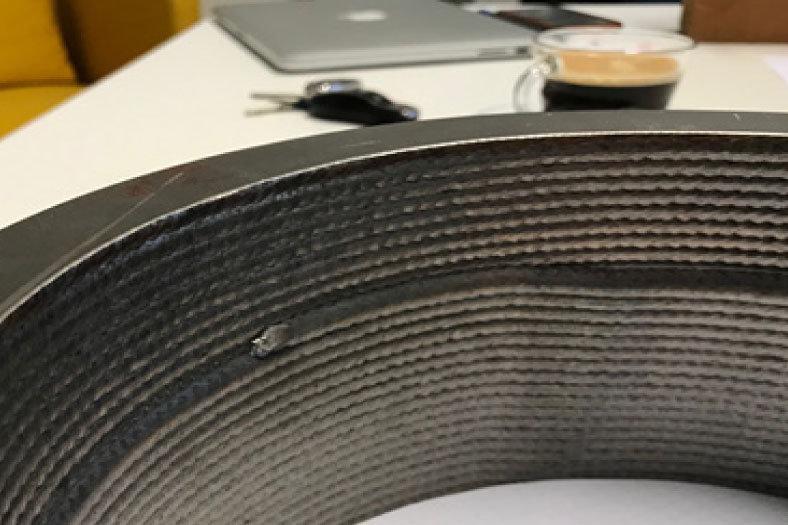

There are different modern MAG welding machines made to reduce the heat input and spatter formation. All these methods use different types of pulsing techniques. But they also use advanced wire feeding techniques or altering polarity to influence the heat and material transfer.

AC aluminium pulse GMAW process

AC Aluminum Pulse (GMAW) brings features that cannot be realised with standard DC pulse MIG welding. The AC pulse process reduces the heat input by focusing the energy away from the base plate and switching the polarity of the arc. Productivity increases with improved deposition rates using AC Aluminum Pulse (GMAW) waveform technology.

This is possible because the negative polarity arc redirects the heat away from the workpiece, reducing the chance of burnthrough.

Synergic welding in AC aluminum pulse

AC Aluminum Pulse waveforms are synergic weld modes. Based on the wire feed speed, set by the operator, a preprogrammed voltage is automatically selected. The Arc length is fine-tuned by using the Voltage adjustment.

Hot wire GTA welding has been developed to improve the deposition rate through heating of the filler wire. This process is suitable for almost all the materials. Hot wire GTAW setup consist of TIG power source, hot wire power source for heating the wire, wire feeder with special vibrating arrangement for wire and wire feeding mechanical arrangement on TIG torch. Apart from advantages of TIG process, it can replace the MIG process for its deposition rate.

Advantages of hot wire TIG process will include:

• Very high welding speed as compare to normal TIG process. It can weld up to 1.2 meter/min.

• Excellent weld appearance

• Excellent penetration achieved up to 8mm depth

• No fumes and no post welding process such as grinding

• Due to high deposition rate, this process is most suitable for cladding operation process

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.