A commitment to recycling processed water for industrial purposes

By OEM Update Editorial June 9, 2021 3:45 pm IST

These are some of the smart things that we have added to our factories. On the water usage, we use pumps to boost the water directly instead of running the pipes and pumps round the clock.

Sanjeev Sirsi, Head – Municipal Business – INDO Region, Water Utility, Grundfos India, in an interaction with Megha Iyer, talks about their commitment to resent water wastage and elucidates their offerings that can minimise the same at industrial level.

Implementing wastewater management at plant level

I think earlier, there were no methods to measure your requirement, usage and wastage of water at your industry or plant level, which further led to wasting water. The moment the industries found ways to measure the water utility, they started realising the importance of making measured use of available water in terms of quality and quantity. That’s when one starts thinking on what’s to be done with this quality. How do I get to know about it, as the pollution control board is making their respective norms stringent every other day? Following to which, every single person, every single body, at the industrial level, municipality level has to ensure on delivering the prescribed quality output. This realisation made it quite simple for Grundfos to understand your expectations and create a workflow pattern by drawing to design that will gratify your needs.

Fighting the environmental challenges

Grundfos is completely related to SDG 6 and 13. We have made a commitment at the UN that we will initiate possible measures to comply with the climate change and contribute in building a healthy environment. We also mentioned few points in the SDG that we’re looking at, and pledged on providing safe drinking water to millions of people. So, we have certain parameters which are built in into Grundfos’s preamble. This makes things more open to access and drill down the critical aspects and focus on them. Climate change is nothing but scarcity, in terms of unavailability of water, poor access to water, and floods among the others. Why is the water scarcity happening? There is water scarcity because we are mercilessly taking our water from the ground, without realising the consequences.

Following a few incidents that shattered several cities, we as a company are involved in programs and plans for rejuvenation of lakes; not as a part of CSR but an attempt to make things more accessible. Grundfos is more conscious on developing solutions to make better water for everybody. We also believe in investing in factories and investing in our people. So, the whole idea is about give it back to the people and to the nature. So, keeping that in mind when we started off actually, when I started their operations here in India, 20 years back, and with the kind of service profile we hold amidst our customers, today, we are platinum rated organisation.

So, there is not a single drop of water which goes out of her factory. It says at LD, what they call the zero-liquid discharge, okay. So, we get back whatever is the enemy planted back all the trees which were taken out from the compound back into the same place, ensuring that we don’t disturb the ecosystem. Grundfos revolves around our concepts on developing solutions for the user, solutions that are environment friendly.

We are working with government, smart cities, and stake holders by giving them a direction to pursue the same. By collaborating with the government and industries, we are being able to save the two essential commodities, water and power. Our whole mantra stands on our operations. Look at the smart SDG 613 are embedded into our 2025 Action Plan; every decision was to take every product or every solution or we try and see we’ll link it through those.

We were a part of one of crucial projects, where we created flood control stations for one of our clients. We developed a solution for them which can pump out around 48,000 litres of water per second. Apart from setting up a pump for them, we also installed the control units and SCADA. It took 8 years for us to complete the O&M and delivered a final product recently.

Implementing wastewater management in Smart Cities

Water conservation is one of the basic agenda in smart cities, as the non-revenue water (NRW) is a grave concern in all the cities. We are collaboratively working with a couple of companies helping them in water conservation and apt utilisation. In a pumping process, the non-revenue water is ranging between 40 to 50 percent, which means, if I pump hundred litres of water from point ‘A’ but point ‘B’ receives only 45 litres to 50 litres, and the rest is lost. This further makes me clueless about the water loss.Non-revenue water is basically something that cannot be commercialised. So, we are looking at we’re talking to various people saying that how can you identify this non-revenue water the water which is not being used to make money which means leakages is the main thing and the second portion is a commercial problems and metering problems as a but that’s very less that can be sorted out.

Now, what if I can use that power and give you the same, through your district metered area (DMA) and to reuse the additional waste or power. It means, when my system reaches its maximum capacity for the day (10 hours) uninterrupted, it will send signals, an alarm indicating that there might be a problem. This is possible due as we have sensors installed in those pumps; we can locate the problem / leakage area and repair it instantly. I think people won’t mind paying for water meters, so as to make appropriate and controlled utilisation of available water, especially when these water meters are technologically advanced. Consumers today are smart, they know importance of controlled water consumption, and this it can drive the consumption pattern among the consumer themselves, and further modifies their overall routine consumptions.

Latest products and innovations in your basket

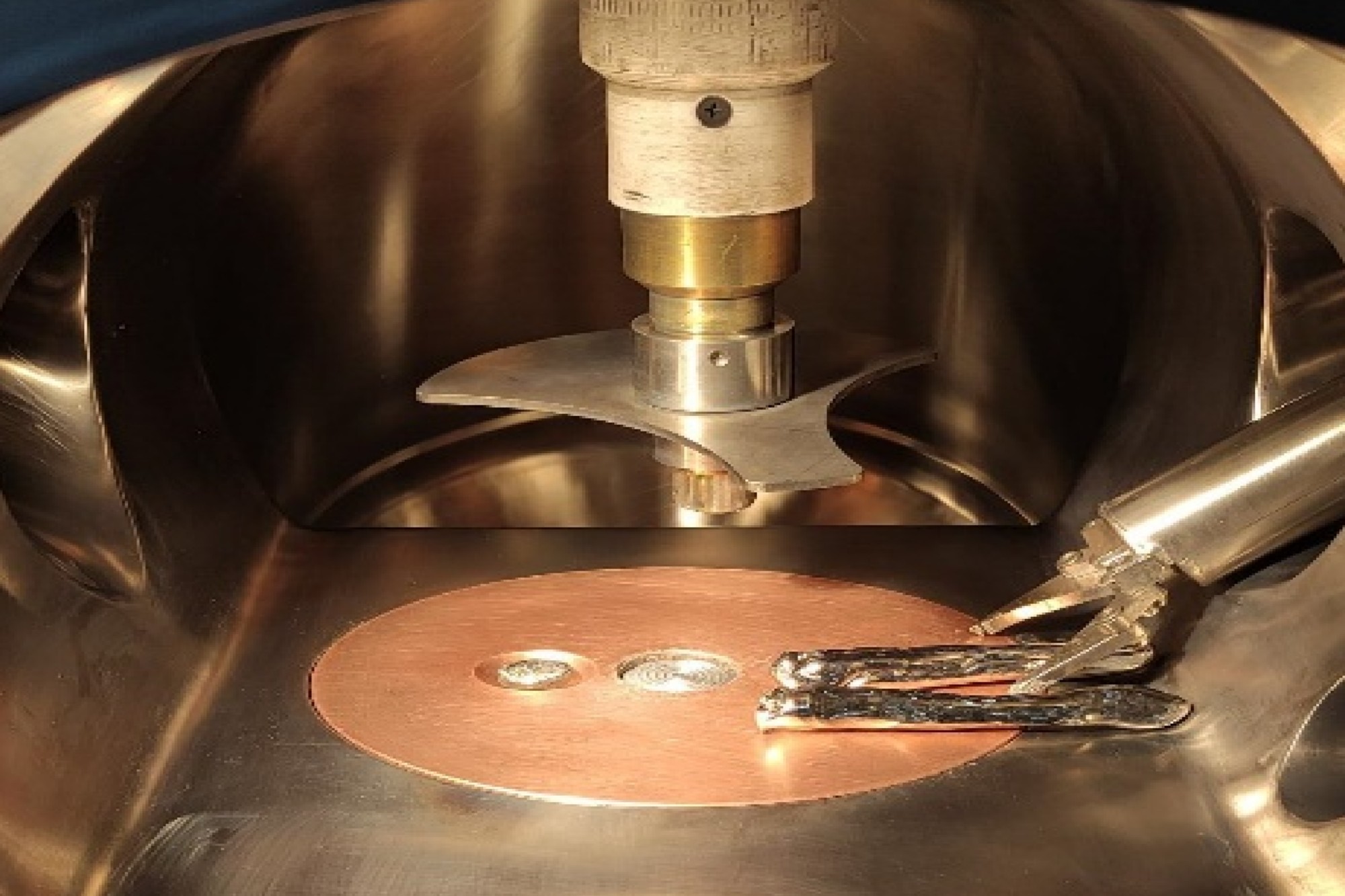

We are not just product oriented, but are equally keen in providing better solutions for our customers. Being a pump manufacturer, we don’t just manufacture pumps, but we also create solutions that fit best for the environment and the surrounding where our product will be installed and utilised. And this is where technologies like, AI, smart pumps and smart products comes into the picture. These technologies help you conduct a preventive maintenance on your products before it breaks down. So, we have sensors installed in our pumps that indicate a sign whenever it reaches its exhaust level require a maintenance.

Solutions to be expected in coming years

Every day is a discovery. We keep learning new things every day. It’s all about the user expectations and our consumer’s demand, which keeps changing every day. Like, we have implemented AI in most of our functions. When a service executive couldn’t solve an error or an issue, he uses Helo lenses through which he can transmit the system’s data to someone who can bring a solution by considering the required parameters. It’s all about reaching fast to your customers, and provides best fit solutions at the earliest, whilst reducing the machines downtime. Since Helo is quite expensive, so we are looking at plug-in sensors.

Grundfos solutions for Smart factories

The idea behind becoming a platinum rated building was, we wanted to walk the talk, we said we will increase efficiency in every product; like treating the water being used in kitchen and reuse the for gardening and related purpose. We have a solar farm counted down which you hardly use because we are using ZLD, we had the air conditioning for the complete office and the factory’s empty office areas. If you actually go by the theoretical means, we required approximately 120 tons of chiller. Instead of going for 120-ton chiller, we went for 80-90 tons chiller, during the night time when the power charges are less, we convert water into ice and remaining 30 tons we take from the melted ice. This is driving my power consumption down.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.