Self cleaning disc filtration systems: advanced tertiary treatment technologies

By admin July 16, 2015 11:19 am IST

Tertiary cleaning systems from Amiad India offer promising solutions for effluent treatment in textile industries

Filtration of suspended impurities, both inorganic and organic in nature, is one of the most important steps in Effluent Treatment Schemes since efficient removal of these suspended impurities is very critical for sophisticated downstream technology like UF membranes or even for quality process water. With the long due pollution control norms now in place, even disposal of treated effluent mandates suspended solids from tertiary treated water to be a bare minimum.

Pressure sand filters, dual media filters etc. have been used extensively in the past with well-known operation and maintenance issues such as bio fouling, sand slippage, channeling effect etc. which hampers the downstream water quality. However with the advent of newer filtration technologies, we now have options available to fine tune filtration scheme and downstream application in ETP systems.

A good filtration system in Tertiary Treatment must be capable of handling organic and inorganic suspended load with ease, along with minimum cost towards civil construction, small footprint, minimum water rejection in backwash and 24×7 uninterrupted operations. This is where Self Cleaning Disc Filtration Systems offer a very good alternative.

Self-Cleaning Disc Filtration SystemsSelf-Cleaning Disc Filtration System offers a plethora of advantages over conventional filtration technologies in ETP Tertiary Treatment Schemes. These filters offer particle filtration based on micron cutoff philosophy, working on absolute filtration principle rather than nominal.

A 55 micron disc filtration system for 10 – 20 ppm of TSS in Secondary treated water can offer considerably high level of protection to downstream equipment such as UF Membranes, provide high quality process water or comply with the pollution control norms for safe disposal.

This offers a greater level of credibility to ETP designers when accessing downstream water parameters for ETP schemes in Tertiary Treatment. To top it they are completely automatic in operation with dedicated PLC controllers to monitor filtration and backwash sequence, thus eliminating labor intervention.

Self-cleaning Disc Filtration System DescriptionDisc Filtration Systems essentially comprises of an assembly of Filter Pod which houses the filtration spine, along with header manifolds, 3 way valves, DP switches, hydraulic command tubes, pressure gauges and a PLC controller. The heart of the system is the filtration spine which is essentially a stack of grooved discs which acts as the filtration media. These filters essentially have a filtration and backwash sequence.

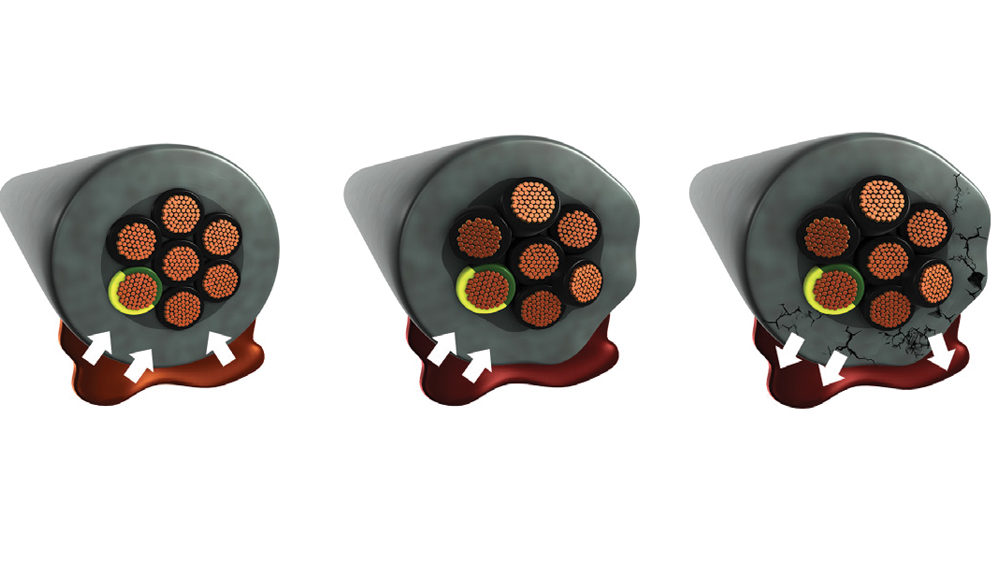

The Filtration SequenceThe grooved discs are stacked on the filtration spine and assembled according to pre-determined water filtration requirements. During filtration, the discs are compressed by means of a pre-loaded spring and differential pressure, forcing the water to pass through the grooved disc surface, thus trapping the solids.

The Backwashing SequenceActivated by a pre-determined time command or differential pressure, the system enters backwash mode. The inlet valve port shuts as the drain valve port opens. During the backwash process, pressure is released and the spine’s piston elevates, releasing the compression on the discs. Tangential jets of filtered water are then forced through the nozzles positioned along the spine. At this stage the discs spin freely, loosening the trapped solids which are then flushed out. During the flushing cycle each filter pod is backwashed sequentially, while the other pods continue to supply filtered water downstream. When a pod begins the backwash cycle, the system valves automatically reverse the flow in the pod, allowing filtered downstream pressurised water to backwash the filter. The backwashing sequence lasts 15 – 20 sec per filter pod, during which time the rest pods are still in filtration mode and provide uninterrupted filtered water, downstream.

Disc Filtration System advantages

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.