Connecting Smart Manufacturing

By OEM Update Editorial August 14, 2017 3:23 pm IST

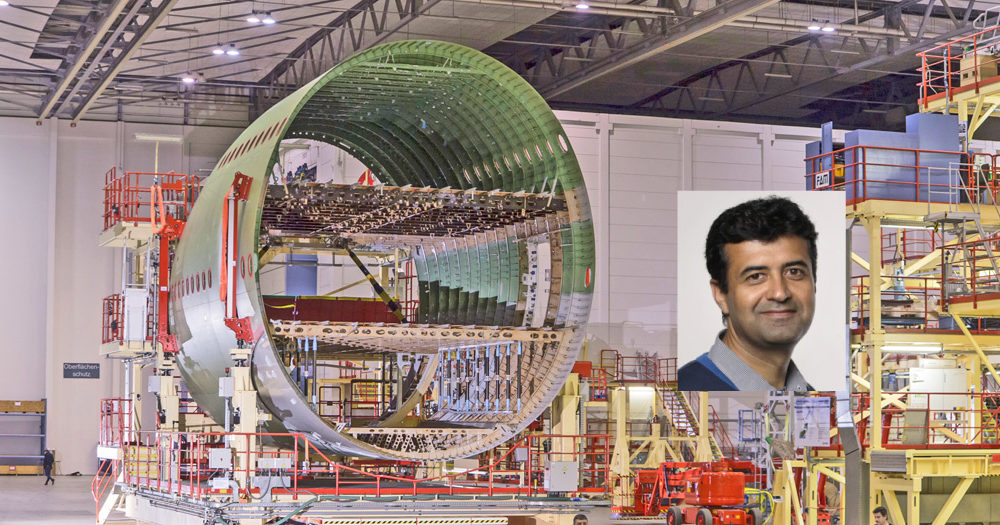

Marc Jarrault, Managing Director, Lapp India elucidates the role of cable and connection technology in the era of smart factories.

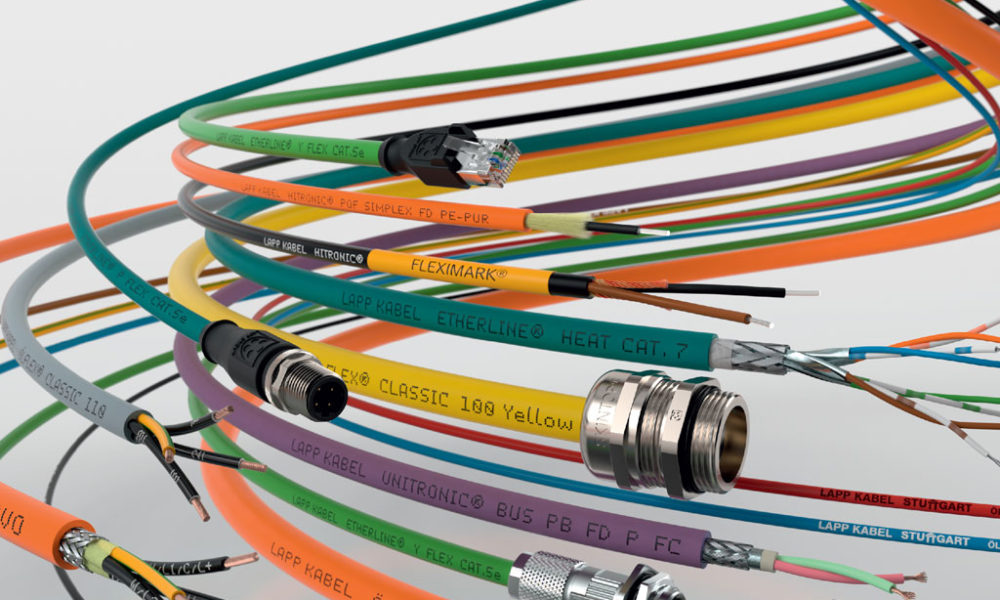

Mass adoption of digitisation across economies and societies has led to emergence of Industry 4.0. In the course of Industry 4.0, the demands on cable and connection technology will also change. Data rates will climb with the consistent networking of company and business processes, a development that demands high-performance networks. In future, network cables will no longer only be used to connect machinery and within control cabinets, they will also be laid directly to intelligent actuators or sensors in the field. The solution lies in system-specific field-compatible Ethernet cables and robust connectors. Industry 4.0 creates what has been called a ‘smart factory’. Smart Factories enables a business to be more plugged in to the Industrial Internet of Things. This allows a business to look for ways to identify, isolate and prioritise the predictable and repeatable components of processes. Flexibility and one-off production are the main aims of Industry 4.0, enabling companies to achieve resource efficient and ergonomic production, with dynamic integration of their customers and business partners into the value chain. The technological basis for this vision is the Internet of Things. It links cyber-physical systems, i.e., intelligent objects with embedded hardware and software, in a global network. The phenomenon is set to become increasingly important for industrial production in the coming years.

Trends and requirements born out of the Industry 4.0 revolution also influence the connectivity level of a machine or system. In Industry 4.0, development and production processes become more flexible, more efficient and more customer-specific. As customers demand customised systems and higher flexibility, industrial automation components should reflect these demands. In the new industrial revolution, products are becoming ‘smarter’. Cables and connectors are currently being developed that enable machines and systems to become modular. With customer’s increasing demands that products be customised and production be flexible, cables and connectors have to make these machine requirements a reality. Efficiency of cable and connectors is key to the productivity of the future of the industrial sector.

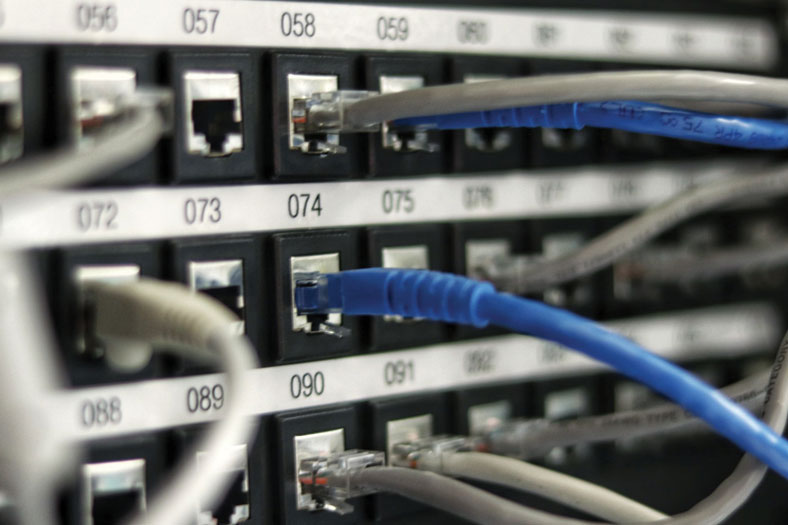

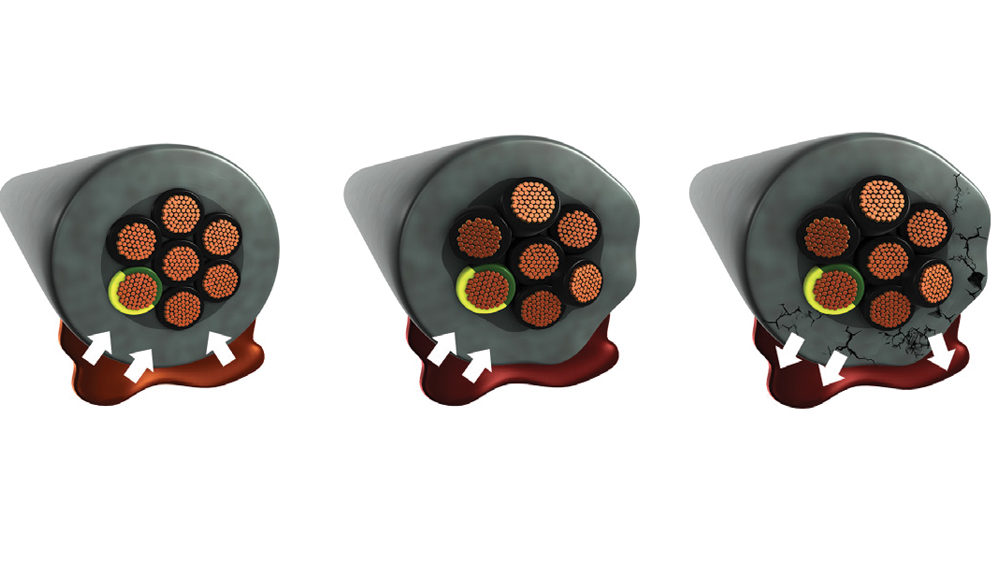

Essentially, in a truly smart factory, the manufacturing process becomes transparent from A to Z, and this transparency goes beyond the factory floor to the supply chain to the delivery process and stretches out to the user experience. Reliable networking of production across all levels is only possible with a comprehensive cabling and connection concept. Ethernet cables in a production environment must be substantially more robust than LAN cables in an office environment. It is an enormous challenge to combine the requirements of flexibility, robustness and the highest data rates. In addition, it must also be possible to install network connectors in the field without special tools.

This represents a turning point that offers enormous opportunities and at the same time confronts the sector with enormous challenges. It is only with consistent, interdisciplinary collaboration of all involved participants from industrial machinery, electrical engineering, automation and information technology that uniform, ground-breaking standards can be created and the future can be shaped. Component, system and solution providers must all change the way they think. The solution lies in system-specific field-compatible Ethernet cables and robust connectors.

Marc Jarrault,Managing Director, Lapp India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.