Choosing the Right Lubricant

By OEM Update Editorial February 14, 2018 12:58 pm IST

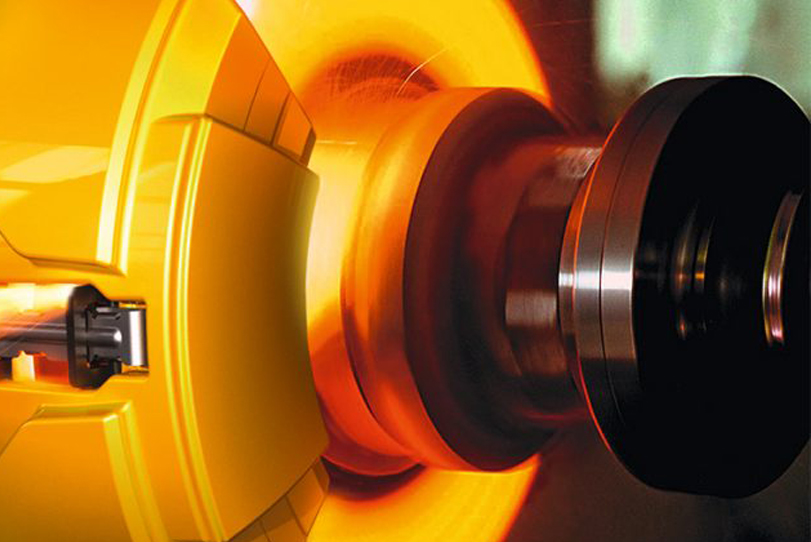

Reducing friction and ensuring productivity by evaluating the right lubricant for machine tool slideways.

Friction is the force that opposes the relative motion of two surfaces in contact. Solid surfaces that appear smooth to the human eye are actually not when examined minutely. They are rather rough and opposing surfaces scrape against each other producing surface wear and tear due to the friction created. Hence it is important to have solutions that protect the machine, improve productivity, efficiency and reliability as well as maintain environmental protection.

Friction can be either ‘static or break-away’ friction which is when a machine which has been at rest is turned on. Herein, the force applied to turn the shaft must first overcome the interactions between the two surfaces. As the shaft begins to rotate, ‘dynamic or kinetic’ friction comes into play.

As a result of the shaft rotation, lubricant is “dragged” into the contact zone, which reduces surface-to-surface interactions and thus causes friction forces to drop. With increasing speed, the lubricant film in the contact zone increases too and friction drops further. When surfaces are fully separated by the lubricant, friction is reduced to a minimum. If speed continues to increase past this point, friction increases again as the lubricant film grows and generates viscous drag.

Among the many types of lubrication regimes are three major categories that one needs to be cognizant of:

- Boundary lubrication: Where friction is dominated by the properties of the surfaces.

- Mixed lubrication: Where both the properties of the lubricant as well as the properties of the surfaces affect friction with a ratio depending on speed.

- Hydrodynamic lubrication: Where friction is governed by the viscosity of the lubricant film.

Minimising friction is not the lubricant’s only prime target for many applications, this is simply not good enough in machine tool slideways. Smooth and precise slideway operation/s require special attention to the friction properties of the lubricant. Loss of frictional control can cause inaccuracies, which in a metal removal process, ultimately results in lost machine tool productivity.

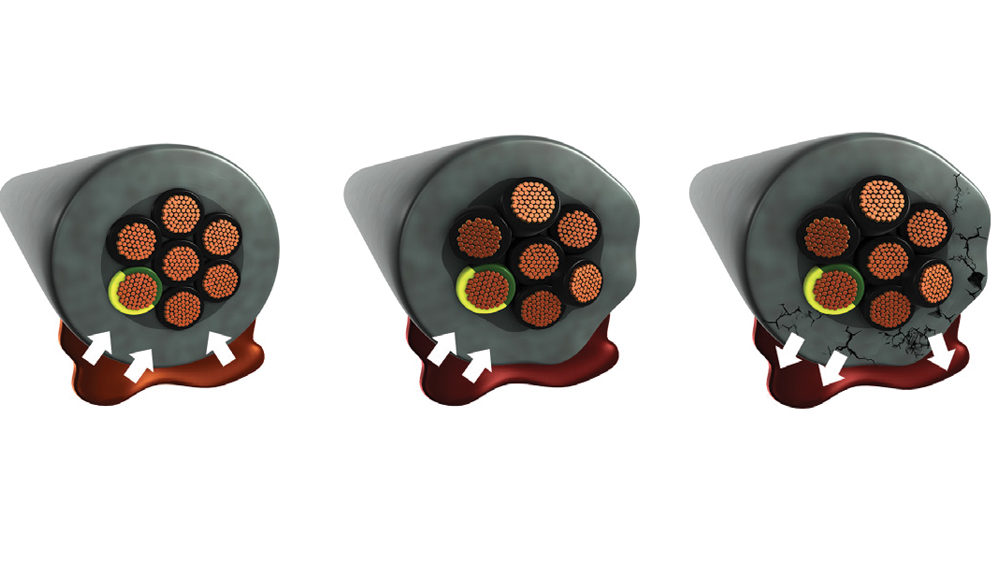

Slideways, also sometimes referred to as linear bearings, and require the same lubrication principles as described above. The differences are that the two surfaces in contact are now flat and the motion is linear instead of rotational. While a plain bearing is designed to operate under hydrodynamic conditions and theoretically could do so forever, slides have to stop when the end of the way is reached, and start moving again in the opposite direction. Therefore, and because slideways typically operate in a stepwise manner, mixed lubrication plays a more important role. Most significantly, slideways are far more susceptible to a phenomenon known as stick-slip due to the large amount of time that they operate in a mixed-lubrication regime.

Stick-slip is a phenomenon caused by continuous alternating between static and dynamic friction. It can occur when static friction exceeds dynamic friction, and when there is some elasticity in the system. When a driving force is applied, high static friction prevents the slide from moving immediately. Instead, the force is loading the spring, by which the driving force exerted on the slide is gradually increased. When the force of the spring exceeds that of the static friction, the slide starts moving. Due to the change from static to dynamic friction the spring force accelerates the slide, while the spring unloads rapidly. Eventually the spring is completely unloaded and starts opposing the slide movement. The slide slows down, while friction for mixed lubrication grows rapidly, until finally the slide comes to a halt and the cycle starts all over again. This jerky movement is what is often referred to as stick-slip.

While it may not be visible to the human eye, stick-slip is all around us, producing a range of very audible experiences. Stick-slip renders possible the experience of an enjoyable violin concerto, but also causes the less enjoyable noise of the teacher’s chalk on the blackboard or the brakes of a train coming to a halt at the platform. Stick-slip is responsible for the jerky motion of windshield wipers as well as the squeaking sounds of a loose drive belt. Car drivers making their tyres squeal by abruptly changing speed or direction unknowingly make use of the stick-slip effect. The small list above gives a flavour of how undesired stick-slip is in most situations. This is especially true for slideways, where stick-slip may cause jerky movements of the slide and the attached work piece or tool. Such uncontrolled motion can result in inaccurate machining operations, unacceptable finished part quality and lost production.

To facilitate smoother operations, special additives called friction modifiers may be added to the lubricant to allow for better friction control. Modern slideway lubricants usually contain a synergistic mix of friction modifying additives that enable accurate and smooth operation over a range of operating conditions.

Modern machine tools and slideway designs demand more of the applied lubricants. Increasing speeds and loads as well as greater expectations for machine accuracy require highly sophisticated slideway lubricants. In addition, there are an increasing number of friction material pairings (e. g. metal-on-plastic) that have different lubrication needs.

It is critical to choose the right slideway lubricant for machine tools that will help to improve the productivity of the equipment, protect the parts as well as prevent friction stick-slip. There are several recognised friction tests to demonstrate frictional properties of slideway lubricants such as:

- Cincinnati Lamb Friction Test

- SKC Tribometer

- Darmstadt Rig Test.

These tests allow evaluation of static and dynamic friction characteristics of a lubricant and the effect of various slideway materials.

Mobil industrial lubricants are developed by working closely with leading equipment builders. Mobil engineers gain deep insights into equipment trends and lubrication requirements to guide lubricant researchers and formulators in designing highly effective lubricants which are specially formulated to:

- Protect your equipment

- Enable problem-free operation in high or low temperatures, wet environments and under high loads

- Provide longer lubrication intervals.

Available in a range of viscosity, to offer customers the right choice for their applications, Mobil industrial lubricants can help enhance performance, reduce cost and waste, and improve industrial productivity.

Authored by:

Shankar Karnik,

General Manager Industrial, ExxonMobil Lubricants Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.