3 ways edge computing will benefit smart manufacturing

By OEM Update Editorial October 7, 2020 3:43 pm IST

It is estimated that there will be 41 billion Internet of Things (IoT) devices by 2027, but how can manufacturers access the full benefits of this revolution? Here, John Young, APAC director at automation parts supplier EU Automation, identifies the three main ways edge computing will benefit smart manufacturing in the coming years.

In simple terms, edge computing refers to locating computer processing of data as close to the source of the data as possible. According to research by Gartner, around ten percent of enterprise-generated data is created and processed outside of traditional centralised data centers or the cloud. It is estimated that this figure will rise to 75 percent by the middle of this decade.

Although edge computing is in most respects the polar opposite of cloud computing, the two technologies will likely prove most valuable when used together as part of a hybrid data architecture. However, here are my three Ss for understanding those areas where edge computing really does have the edge:

Speed

Speed, or reduced latency, is central to the potential benefits of edge computing. Latency, in case you didn’t know, refers to the time taken between data being sent from an IoT device and when it returns to the same device. Even if we are talking about milliseconds, there are certain applications where reducing latency is critical.

The best example given to explain the importance of this is autonomous driving, where the data generated by smart sensors needs to be acted on in real-time to prevent accidents. However, there are many other potential uses in the world of manufacturing. Edge computing promises to reduce the risk of accidents caused by machinery and allows manufacturers to monitor the health of factory equipment in real-time.

Security

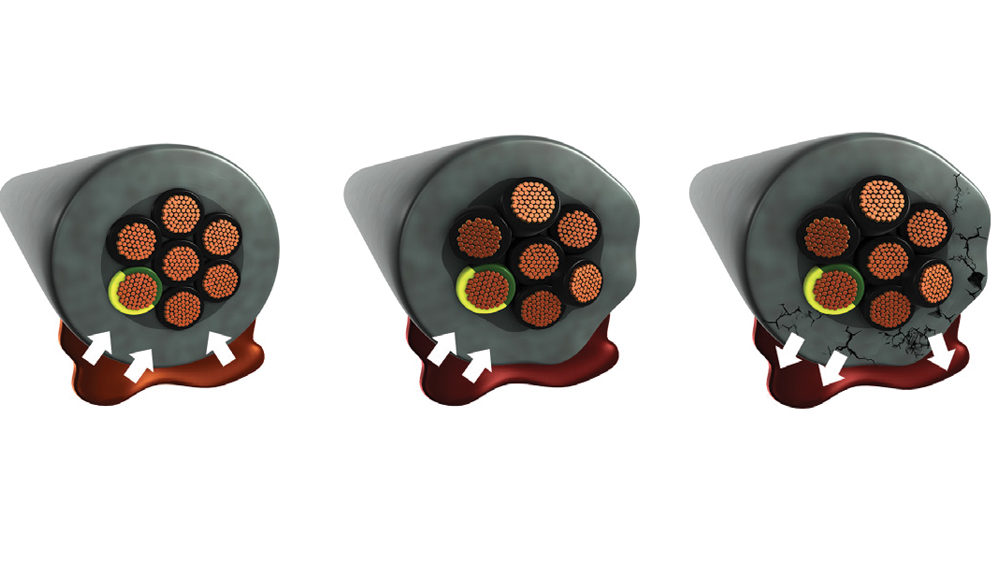

SavingsIf implemented correctly, edge computing can also help manufacturers save money. As already discussed, it reduces the risk of downtime caused by network outages. It is also a key enabler for more effective predictive maintenance.

By gathering, processing and acting on data in real-time, with the reduced latency offered by edge devices, manufacturers can be sure that if an automation part or an item of machinery is about to fail this will be acted upon quicker than ever before. Replacement parts can be ordered from a reputable supplier before money is lost to unplanned downtime.

Cloud subscriptions, along with the volume of bandwidth required for the growing number of IoT devices, can also cost large sums. With edge computing, manufacturers reduce their need for larger volumes of cloud storage and free up bandwidth. Taken together, the above benefits suggest that when implemented in the right way, edge computing can help manufacturers make savings. Furthermore, the very nature of edge computing means it can be implemented in a piecemeal way, without the need for a large upfront investment.

In the time it takes to read this article, approximately 20,087 devices will be connected to the internet. In the next few years, edge computing will be essential in allowing manufacturing to reap the benefits of the IoT. Implemented in the right way, edge computing promises to increase speed, enhance data security and bring savings in productivity and reduced downtime.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.