EOS at the cusp of manufacturing revolution in India

By OEM Update Editorial March 15, 2017 12:22 pm IST

India is an aggressive market for us. We are looking somewhere around 30 per cent y-o-y growth because of the increasing industry acceptance.

Anand Prakasam, Country Manager – India & Sales Manager – ASEAN, EOS GmbH India

EOS enables its customers to produce innovative and high quality products by using solutions on the basis of industrial 3D printing technologies. The company aims to change the usage of this technology from its isolated production environment into the mainstream production technology across the Indian market, informs Anand Prakasam, Country Manager – India & Sales Manager – ASEAN, EOS GmbH India in an interview with Subhajit Roy.

Why 3D printing is being considered as revolutionary technology?

Industrial 3D printing or Additive Manufacturing is a manufacturing technology which enables our customers to produce innovative and high quality products using layer technology. This process enables industry players to cut down lead time, cost, enables manufacture lightweight products and also increases compatibility for batch production. 3D printing is being considered as revolutionary for a simple fact that one doesn’t need any die and mould to create a part – the part can be printed with the help of the machine even if the requirement is of one piece. In a manufacturing process, design defines the cost of final product and if a product is designed smartly with industrial 3D printing using the design rules, and then cost efficiency can be achieved.

Could you brief us about your expertise in this domain?

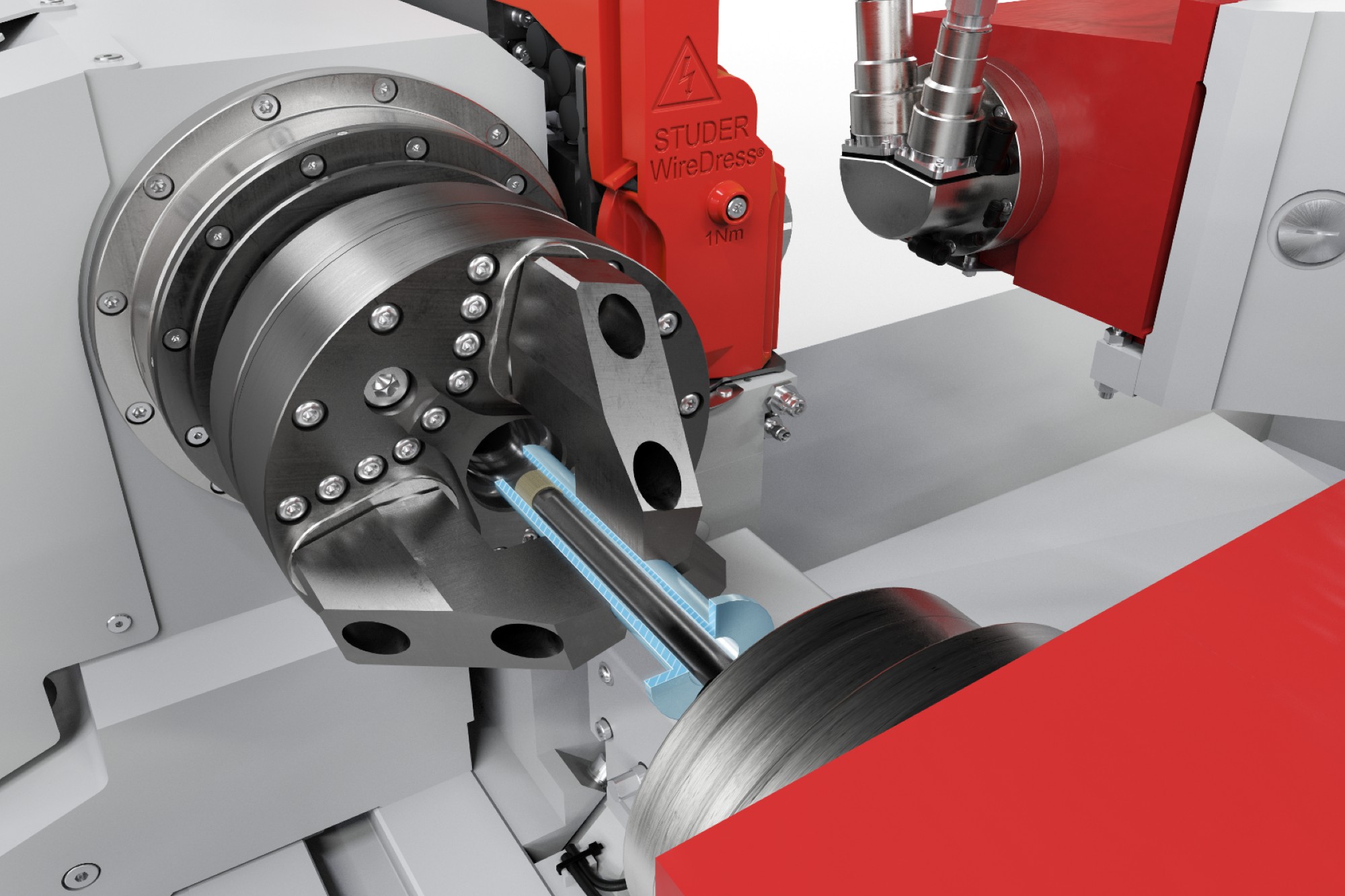

Founded in 1989, Munich based EOS is the global technology leader for industrial 3D printing of metals and polymers. We provide end to end solutions in Additive Manufacturing which includes machines, materials (powders) and the process parameters. The company spends a lot of its revenue in developing these process parameters which ensures that all EOS systems deliver superior part quality and consistency.

How is the concept catching up in India?

Initially, automotive companies were using additive manufacturing technology for rapid prototyping. However, as the technology is evolving, we see a big intake among aerospace and aerospace related companies. The technology has also found substantial traction in the dental industry for products like implants, dental copings and bridges. In the automotive segment, 3D printing can be used in direct part designing as well as tooling. In India, auto majors like Bajaj are still using it in their R&D phase. However, the component suppliers are using it as a tool of die and mould making for their mass production. We still have not seen enough adaption from medical industry despite having tremendous potential in terms of implant due to pending regulatory procedures locally.

Would you like comment on your alliance with Wipro?

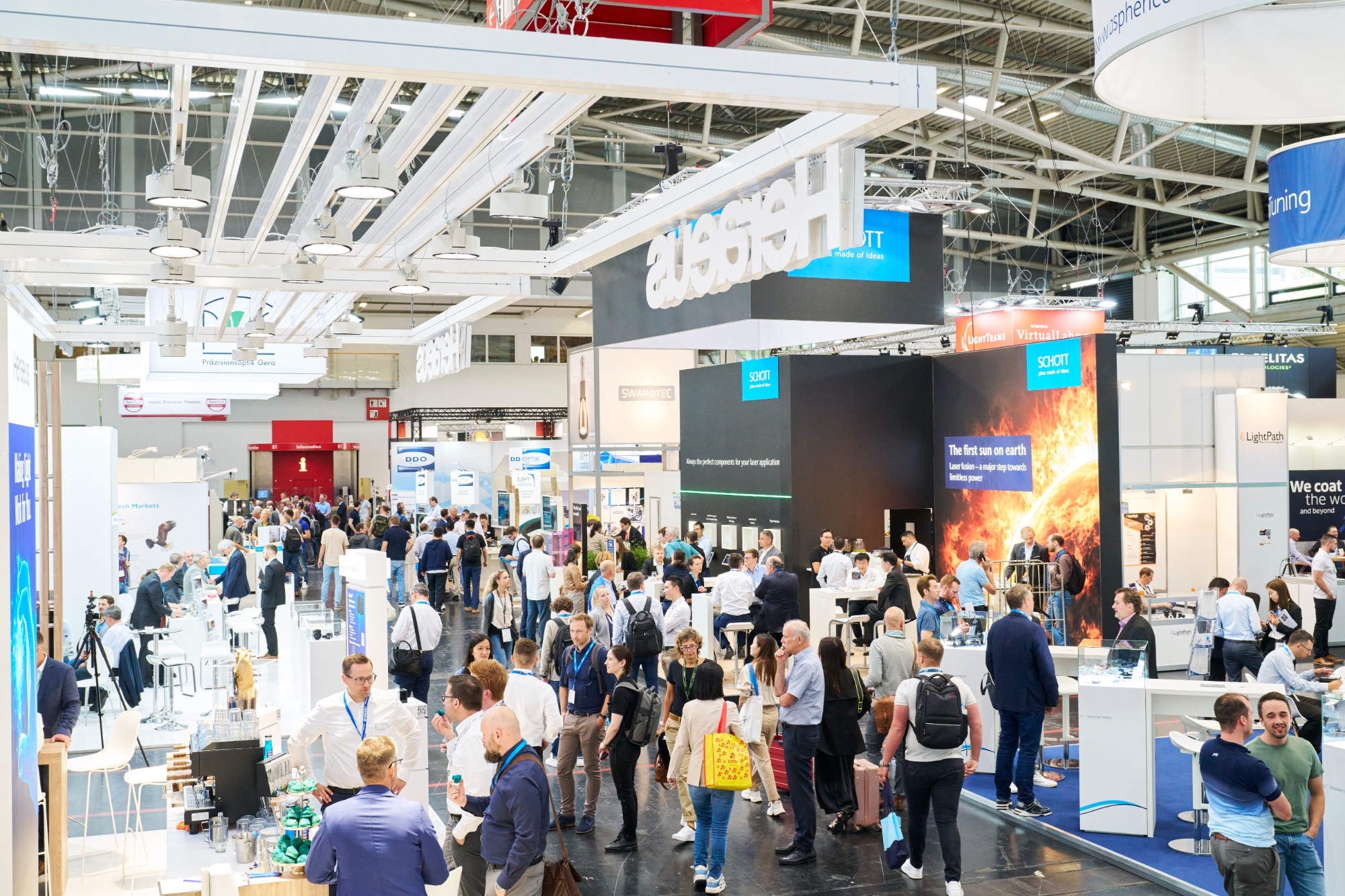

We signed a strategic alliance with Wipro for setting up a state-of-the-art AM solutions- cum- experience centre in Bengaluru. This will offer a unique hands-on experience to customers and help them explore and adopt AM technologies in their businesses. The centre would be fully operational by March 2017.

What are the USPs of your newly launched 3D printer M100?

EOS M 100 is an ideal entry level Additive Manufacturing model for Direct Metal Laser Sintering (DMLS). The machine is designed for dental industry, custom-built medical instruments manufacturing, manufacturing and small precision components.

What are the major growth drivers?

Stringent emission norms in automotive industry and increasing awareness and utilisation of the technology in other industries are driving the demand for 3D printing in India.

What would be your long-term perspective for the Indian market?

The idea is to have industrial 3D printing implemented on the shop floors. Today if we visit any industrial manufacturing set up, we’ll see all their production machines at one area and the 3D printer positioned somewhere else just to build certain parts or just to be a part of the process chain. This has to change because the 3D printer has to come into the production process and then it should be integrated to communicate with the other machines available. Our goal is to change the usage of 3D printing technology from its isolated production environment into the mainstream production technology across the Indian market and all the OEMs.

What kind of revenue growth you foresee for EOS in India?

Our target is to double our revenue in every two years. This year we closed at 315 million Euros globally and would like double the same by 2019. India is an aggressive market for us. We are looking somewhere around 30 per cent y-o-y growth because of the increasing industry acceptance. Today we have about 80 per cent market share on metal side in Indian market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.