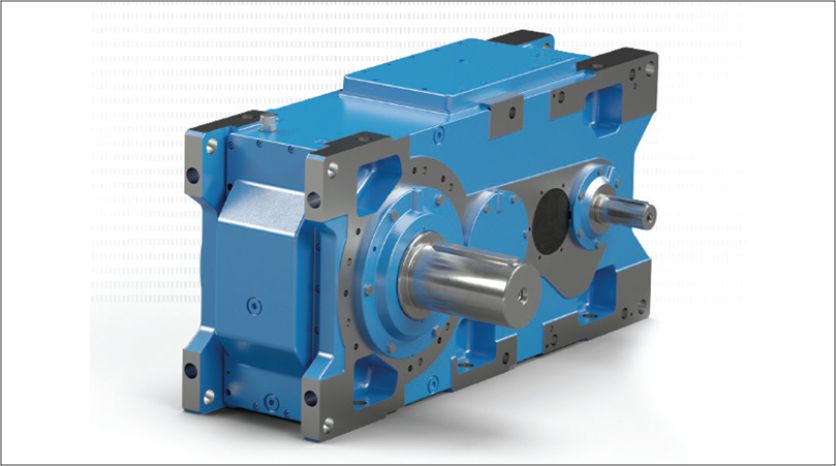

We are exploring the possibility of assembling industrial gearboxes

By OEM Update Editorial June 9, 2022 6:29 pm IST

We have planned to start it by the end of this year, and the management has already principally approved it. By October or November, the production of these industrial gearboxes in India will start. Dhanraj Kalbhor, Managing Director, NORD Drivesystems.

Dhanraj Kalbhor elucidates on the sectors that have driving growth for OEM and points out that the Ukraine crisis has intensified the importance of localisation, domestic markets and exports.

Can you brief us about the kinds of solutions you are presenting here for OEMs

Drive technology solutions are an important aspect of practically any industrial process, and NORD Drivesystems Private Limited, a wholly owned subsidiary of Germany’s NORD GmbH & Co KG, is widely regarded as Indian industries’ chosen partner for providing motion to their machines.The company, which began operations in Pune in 2005, is a market leader in the manufacturing and delivery of motors, drive solutions, frequency inverters, and industrial gear units for mechanical and electrical solutions.In 2007 we started manufacturing started with a small size geared motor, later, we moved on to the bigger size geared motor, but now from this year onwards, we are exploring the possibility of assembling industrial gearboxes We have planned to start it by the end of this year, and the management has already principally approved it. By October or November, the production of these industrial gearboxes in India will start. The geared motor is already there and the entire range from zero frame size to 10 frame size will be produced locally in India.

What are the supply chain challenges which have come up as a result of the ongoing tension in Ukraine?

The situation has led to an increase in exports from India. Since we are present in almost every country like Singapore, Southeast Asia, China, India and Indonesia. It is relatively easier for us to meet up to the challenge. This situation in Ukraine has also led to glitches in procuring components and we are roughly buying 75% of the required components from our subsidiaries. The developments have also intensified the importance of localisation in production and also focussing on the needs of the domestic market. In addition to catering to the domestic market we also have to address the rising demand from the European markets. So from the sales perspective it is a period of good growth. The first quarter itself was excellent. We have grown by almost 20 or 30% Compared to last year’s average. So it’s great, we are ahead of the curve.

What kind of future do you see from the OEM manufacturers which sectors are driving growth?

With time the sectors which grow for us change once it used to be steel and the mines but things change. Steel mines as well as mining industries are in the process of reform, So as a company we keep a track of which sectors can drive growth and remain fully equipped and prepared to meet those expectations. Our presence in the business of manufacturing OEM for the construction sector has paid off really well. Nord is a leading manufacturer of gear motors and gearboxes. Helical Bevel is the most commonly used product in crushing and screening equipment and we are into it as well. We are all aware of the ambitious road building targets and infrastructure targets the government has set up and this augurs well for our business as well. As I see it this is a good opportunity for us to grow and I can foresee this trend will continue for another four to five years

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.