Monitoring shop floor efficiency with digital technology

By OEM Update Editorial October 12, 2021 11:31 am IST

We have started monitoring the shop floor efficiency with digital technology. Making in India drive will certainly help to become ‘Global Manufacturing Hub.

The vision for the country is very clear i.e., Indian GDP to touch $5 Trillion by 2025 and manufacturing to contribute 25 percent of that. Today our GDP is less than $1.3 trillion and manufacturing contributes only 15 percent. So, the growth potential in manufacturing is anybody`s imagination and ‘Die & Mould’ with higher value addition will make greater impact.

Die & Mould automation

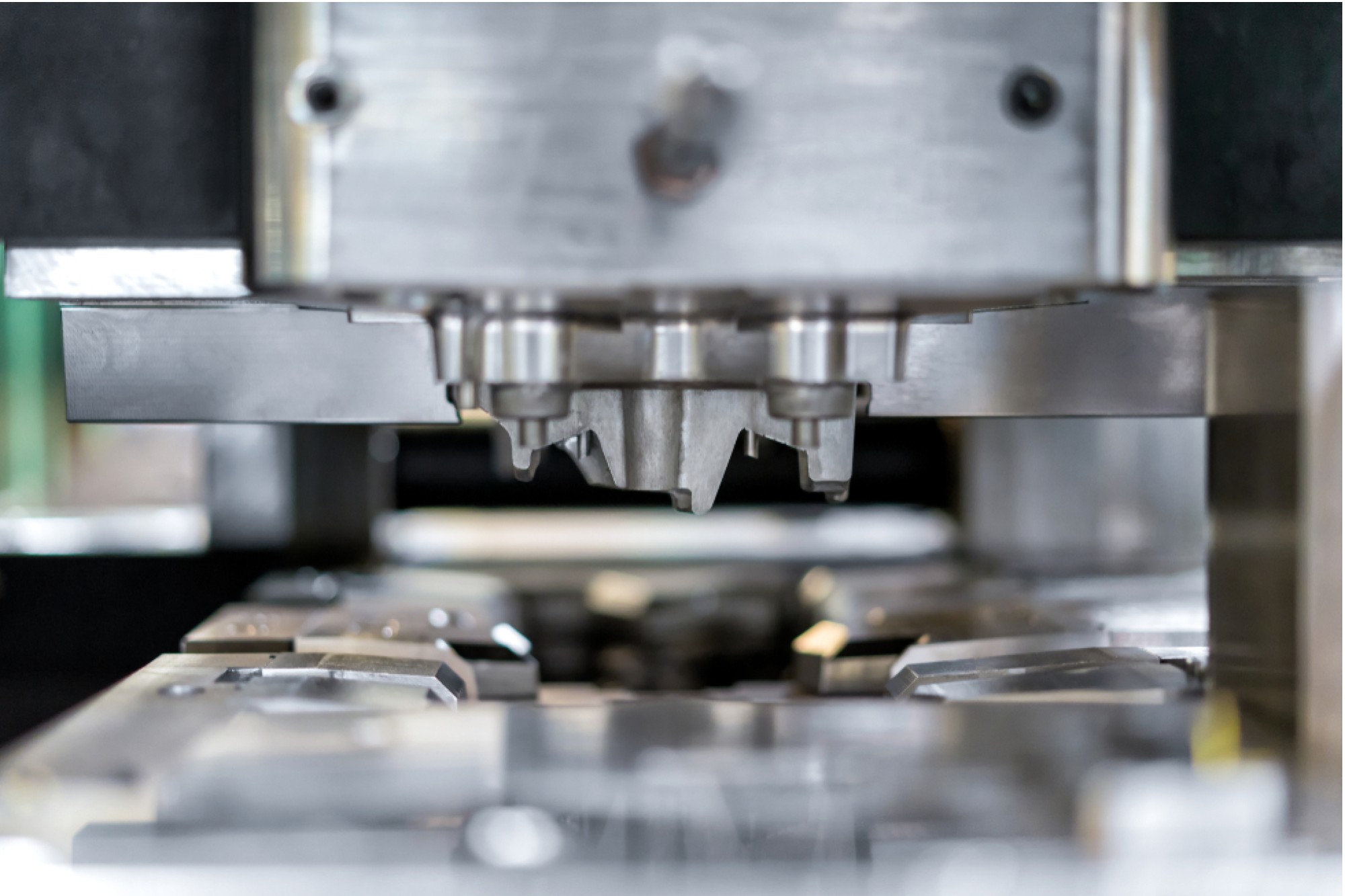

‘Die & Mould’ is called the mother industry of mechanical engineering. Manufacturing Die & Mould is a very complex process which involves the knowledge of the end use of the component coming out of Die/ mould, Metallurgical behaviour of the material of the component, life expectancy of the Die/ mould etc. Apart from the knowledge of the die design, it calls for the knowledge of the characteristics and the properties and the purpose of the e-component to be produced. This is the combination of the knowledge of Metallurgy, Machining technology, Tooling technology and the production process etc.

Let’s see where India stands today in this field. Due to the reasons known and unknown, India stands minimum 25 years behind the developed world, in the development and its technology of industrialisation.The Indian economy started opening up in 1990 but it took 5-10 years for us as a country to acclimatise with this concept of open economy, which was quite obvious. So, real industrialisation started in 2000. It started with white goods such as home appliances, entertainment electronics, automobiles and slowly but steadily now the Defence and Aviation and Aerospace sector.

But this industrialisation was brought by the developed countries. Due to the closed-door economy for more than 40 years, we as a country got isolated from the developments happening in the outside world. This gave a major setback to our education sector. We did not change the academics for almost 40 years in all the fields of education. Let me restrict myself to the education and the skill development required by the industry. ‘Die & Mould’ is one of the most important and fundamental segments of industrialisation which lacked the new technological developments. Though there have been many technical training institutes around in the country but due to isolation the content or the syllabus of the training courses did not change much.

Nevertheless, for the last few we as a country are changing for sure and now, we have acquired the speed not only to match with the external world but to surpass them in near future.

As far as the ‘Die & Mould’ is concerned it is not the automation which would make this industry run but the standardisation that is required. Dies and/or Moulds are not produced in quantities of the same profiles so automation will not help. The standardisation starts from the standard die block/plate so that the tool maker does not spend his time machining. The tool makers’ only job is to machine the profile in the standard die plate available in the market. Then he buys all the standard Die components such as Guide pillars, guide bushes, Wear plates, Cam units, Gas springs etc which reduces the final assembly time. The tool designer has already incorporated these standard die components which are available on the market. Today the delivery time is the bottleneck as compared to China /Taiwan.The world has become so fast now the TTM (Time to Market) has come down by more than 50 percent for all the products. Therefore, the education of the Tool maker on the new technology/technique becomes important.

Secondly, the ‘Making in India’ drive will certainly help us to become a ‘Global Manufacturing Hub’. In response most of the Automakers have already announced that they would increase the indigenisation to the higher level. As a result, many tool rooms are expanding their capacity and infrastructure. Traditionally Auto has been the major customer for Tool rooms. But with the Defence & Aviation/ Aerospace sector opening up, we need to tap these sectors and identify the potential for Tool rooms.

We at FIBRO India, keep adding new products in our manufacturing programme based on the market feedback. We are working very closely with our customers to understand their ever-increasing requirements. For example, we introduced interconnection of the Nitrogen Gas springs in the die to maintain the uniform pressure in every Gas spring in the die to avoid defects in the press parts. We did hand holding with the customers. Now we see an increase in the demand for interconnection of the Gas springs. To educate the customers and make them aware of the new products for die manufacturing we have started ‘FIBRO Know How’ series emailers to which we are receiving good response from the customers. We are proud to state that FIBRO India is the first one to start manufacturing Aerial CAM units in India. FIBRO Germany has very rich experience for more than 70 years of working with reputed Auto OEMs which we are sharing through these emailers.IIOT in Manufacturing

IIoT is the buzz word not only for industry but the day-to-day life of a common man.We find it difficult without the internet. The pandemic has certainly accelerated the speed of digital platforms entering our lives. From the Kindergarten school to working from home to corporate executives, everything is online.

It was quite obvious for the IT sector but even in the manufacturing sector most of the functions like marketing & sales, purchase; accounts Design etc., except actual manufacturing were performed from home. For many of us it was a discovery and in fact it was certainly cost saving for the organisation.With the help from technology, it is possible to monitor the shop floor production remotely. The concept of SMART Factory or Industry 4.0 says the same thing. Industry 5.0 is already on the horizon.

But let’s take a pause and relook, rethink & recover with open eyes. Let’s ask ourselves a few questions to ourselves – Whether this technology will create a civilised society or not? Are we making people jobless? Are we treating humans as machines? Are we making people lazy and dumb?

We need to strike a balance between man & machine. To me, the simple rule is to transfer the laborious, tiring, beyond human reach job to automation and robotics. Letus use this technology to make our job easier and not to offload our complete job to the technology.

During lock down we conducted the online ‘Product Launch’ to which we received an overwhelming response. We did analyse the reason and we came to know that our targeted audience do not get time for such activity while on the job as they are always under time pressure of delivering in the shortest possible time. But during the lockdown they had enough time to attend the webinar. As a result, after the lockdown was relaxed, we started receiving enquiries, orders for the new products which were launched.

We are also planning to implement ‘SMART Factory’ to the extent necessary for us. We have started monitoring the shop floor efficiency with the digital technology i.e., OEE which would help the machine operator, supervisor to identify the areas for improvement. Also online gauging is implemented wherever necessary to assist the machine operator. Similarly, we are using barcode readers in logistic functions to reduce/eliminate human error.

Nowadays, data analytics has become more important to understand business trends, dynamic market conditions, customer preferences etc.

We have started using Power BI (Business Analysis Tool) which is linked to ERP as well as CRM so that we get a real time holistic view of your business at Macro as well as Micro level which helps us to make appropriate strategic decisions.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.